Large-amplitude ultrasonic vibration cutting device

A cutting device, ultrasonic vibration technology, applied in fine working devices, fluids using vibration, metal processing, etc., can solve problems such as low amplitude, improve output power and amplitude ratio, increase vibration amplitude, application promising effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

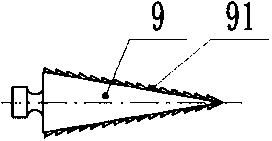

[0026] Such as Figure 1-6 As shown, a large-amplitude ultrasonic vibration cutting device in this embodiment includes a piezoelectric transducer, a primary horn 5, a secondary horn 7, an elastic horn 8, a cutter head 9 and a high-frequency power supply 62. Piezoelectric transducer The piezoelectric transducer is in the shape of a cylinder as a whole, including a bolt 1 and a back cover 2, a piezoelectric ceramic sheet 3, and electrodes that are sleeved on the bolt 1 from back to front and are connected and pressed together. The sheet 4 and the primary horn 5, the secondary horn 7 is fixed on the front end of the primary horn 5, the elastic horn 8 is fixed on the front end of the secondary horn 7, and the cutter head 9 is fixed on the elastic variable The front end of the rod 8, the electrode sheet 4 is connected to the high-frequency power su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resonant frequency | aaaaa | aaaaa |

| impedance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com