Elastic unloading meat grinder

A meat grinding and elastic technology, applied in the direction of processed meat, meat processing equipment, grain processing, etc., to achieve the effect of smooth meat grinding process, prevent motor burnout, and prevent machine failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific embodiments of the present invention will be further described below with reference to the accompanying drawings. It should be noted here that the descriptions of these embodiments are used to help the understanding of the present invention, but do not constitute a limitation of the present invention. In addition, the technical features involved in the various embodiments of the present invention described below can be combined with each other as long as they do not conflict with each other.

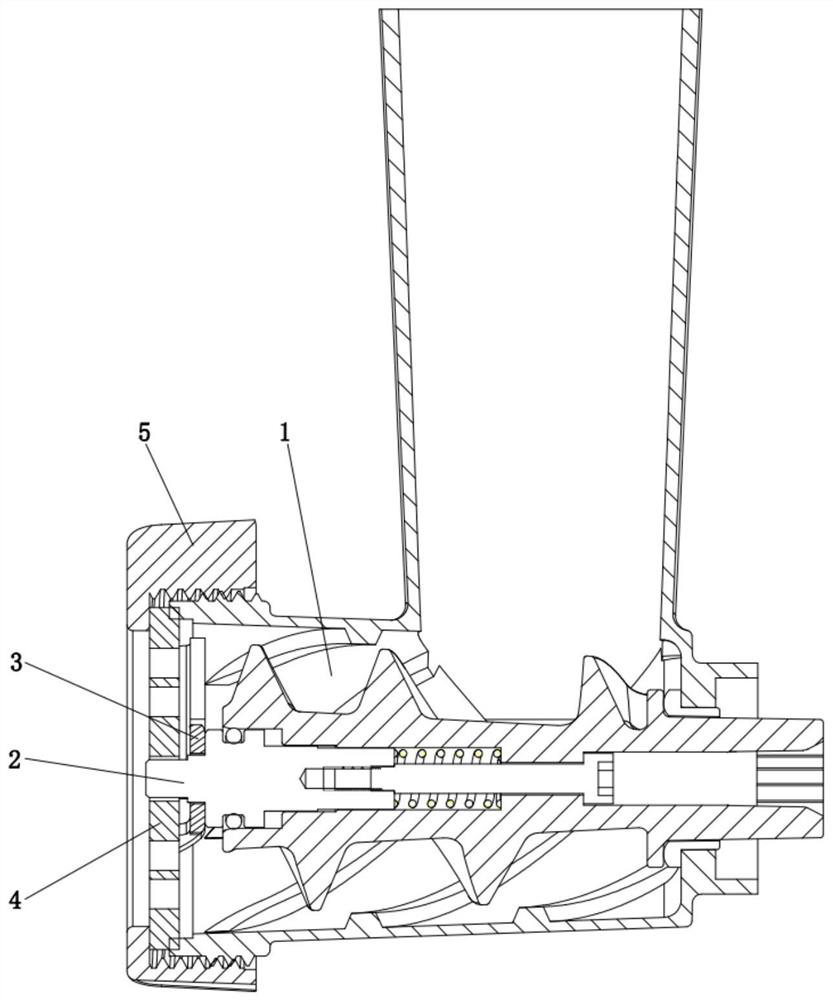

[0015] like figure 1 As shown, the elastic unloading meat grinding device is mainly composed of a meat grinding cylinder 1 , an elastic screw feeder 2 , a meat grinding blade 3 , a screen piece 4 and a nut 5 .

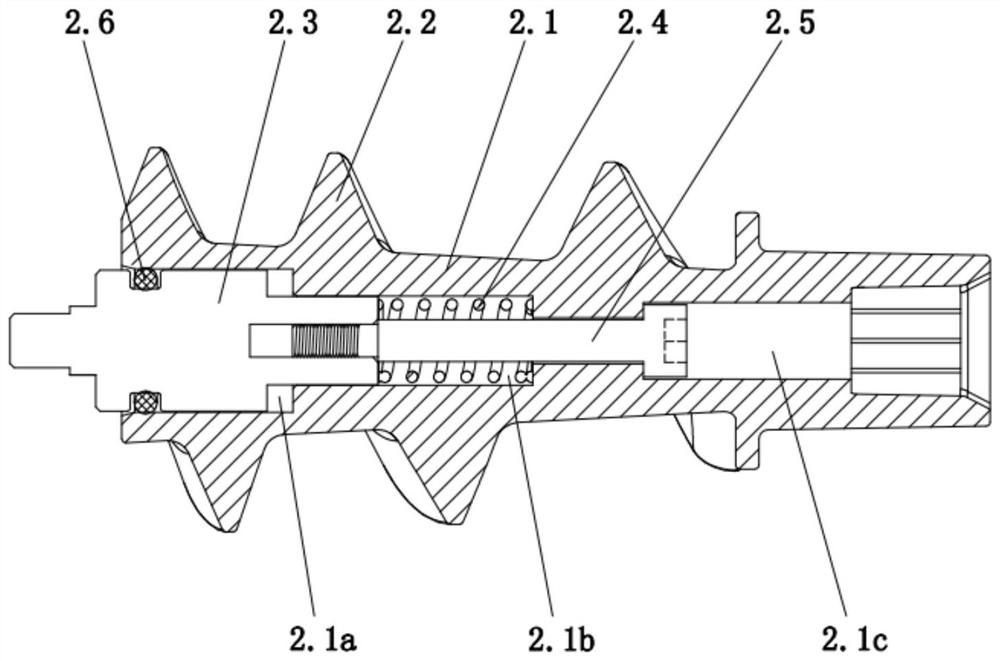

[0016] The elastic screw feeder 2 is composed of a screw shaft body 2.1, a screw blade 2.2, a shaft core 2.3, a spring 2.4, a limit screw 2.5, and a sealing ring 2.6. The spiral shaft body 2.1 is surrounded by a spiral blade 2.2, and the spiral blade 2.2 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com