Composite formaldehyde catching agent and preparation method thereof, artificial board formaldehyde removal method and artificial board

A formaldehyde capture agent and wood-based panel technology, applied in the field of formaldehyde removal from boards, can solve the problems of limited amount of formaldehyde capture, difficult formaldehyde, and easy re-adsorption inside the core board or on the veneer material, so as to avoid pollution and harm the users The effect of causing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

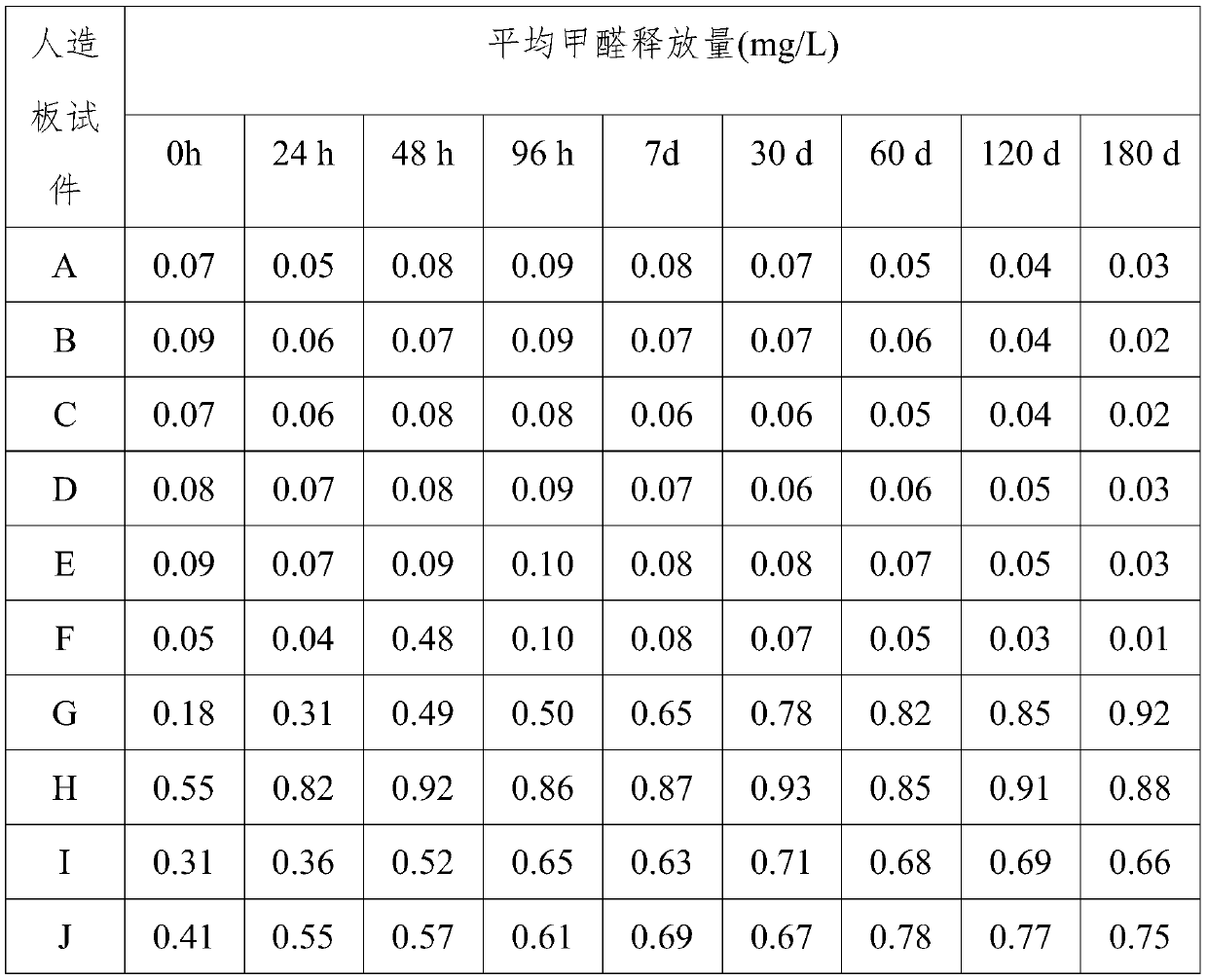

Examples

Embodiment 1

[0042] The present embodiment provides a composite formaldehyde trapping agent, comprising the following components in weight percentage: 8% of IRMOFS material, 3% of modified starch, 0.5% of fluorinated polyether, 2% of xanthan gum, 6% of ethylene urea and Epoxy fatty acid methyl ester 3%, the rest is deionized water.

[0043] This embodiment also provides a method for removing aldehydes from wood-based panels, which includes the following steps: mixing the adhesive and the composite formaldehyde scavenger at a weight ratio of 5:1 to prepare a mixed adhesive; placing the veneer paper in the mixed adhesive Soaking; heat-press the veneer paper soaked with the mixed adhesive on the outer surface of the core board to make a veneer wood-based panel; heat the veneer wood-based panel to 100°C and keep it for 4 hours.

[0044] The above-mentioned composite purifying agent comprises the following components in weight percent: 2% of nano-zinc oxide, 1% of nano-titanium dioxide, 5% of nan...

Embodiment 2

[0047] The present embodiment provides a composite formaldehyde trapping agent, comprising the following components in percentage by weight: 15% of PCN material, 6% of modified starch, 2% of fluorinated polyether, 5% of xanthan gum, 12% of ethylene urea and Epoxy fatty acid methyl ester 8%, the rest is deionized water.

[0048] This embodiment also provides a method for removing aldehydes from wood-based panels, which includes the following steps: mixing the adhesive and the composite formaldehyde scavenger at a weight ratio of 5:2 to prepare a mixed adhesive; dipping the core board and the veneer paper into composite formaldehyde scavenger for 25 minutes, and dried to obtain the treatment core board and the treatment veneer paper; the treatment veneer paper is placed in the mixed adhesive for soaking; the treatment veneer paper soaked in the mixed adhesive is hot pressed on the outer surface of the treatment core On the surface, the veneer wood-based panel is made; heat the v...

Embodiment 3

[0052] The present embodiment provides a kind of composite formaldehyde trapping agent, comprises the component of following percentage by weight: ZIF material 10%, modified starch 4%, fluorinated polyether 1%, xanthan gum 3%, ethylene urea 8% and Epoxy fatty acid methyl ester 5%, the rest is deionized water.

[0053] This embodiment also provides a method for removing aldehydes from wood-based panels, comprising the following steps: mixing the adhesive and the composite formaldehyde scavenger at a weight ratio of 5:3 to prepare a mixed adhesive; placing the veneer paper in the mixed adhesive Soaking; heat-press the veneer paper soaked with the mixed adhesive on the outer surface of the core board to obtain a veneer wood-based panel; heat the veneer wood-based panel to 110°C and keep it for 3 hours; heat-treated veneer wood-based panel The surface is evenly sprayed with a composite purifier, and then irradiated with ultraviolet light for 36 hours.

[0054] The above-mentioned...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com