Scented tea making machine

A tea making machine and scented tea technology, which is applied in household containers, beverage preparation devices, household utensils, etc., can solve the problems of destroying the taste and nutrition of tea leaves, the natural quality of tea water is not high, and does not meet the requirements, so as to achieve multiple cups of tea in rapid succession , enhance the value of commercial promotion, and meet the effect of fast-paced demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

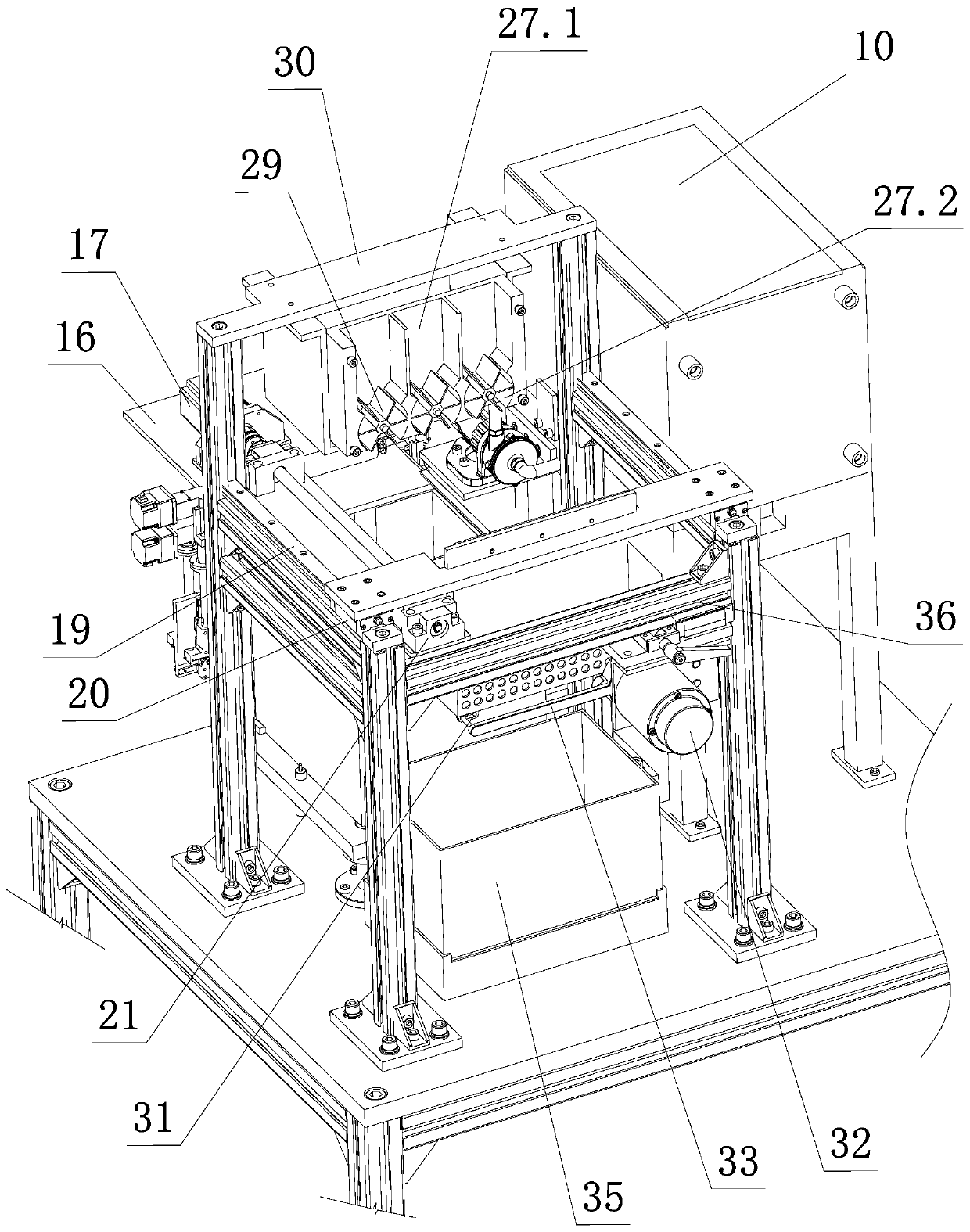

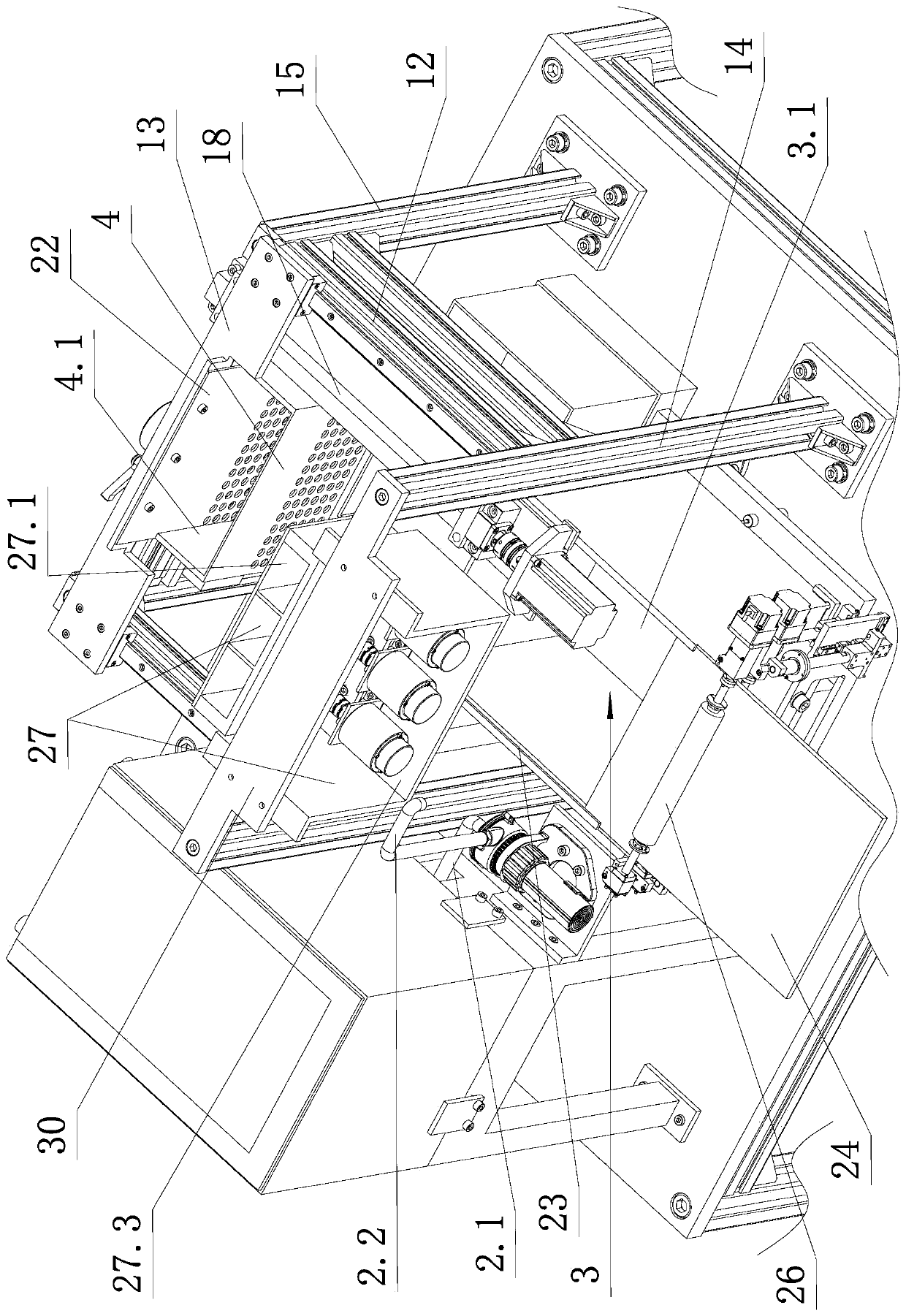

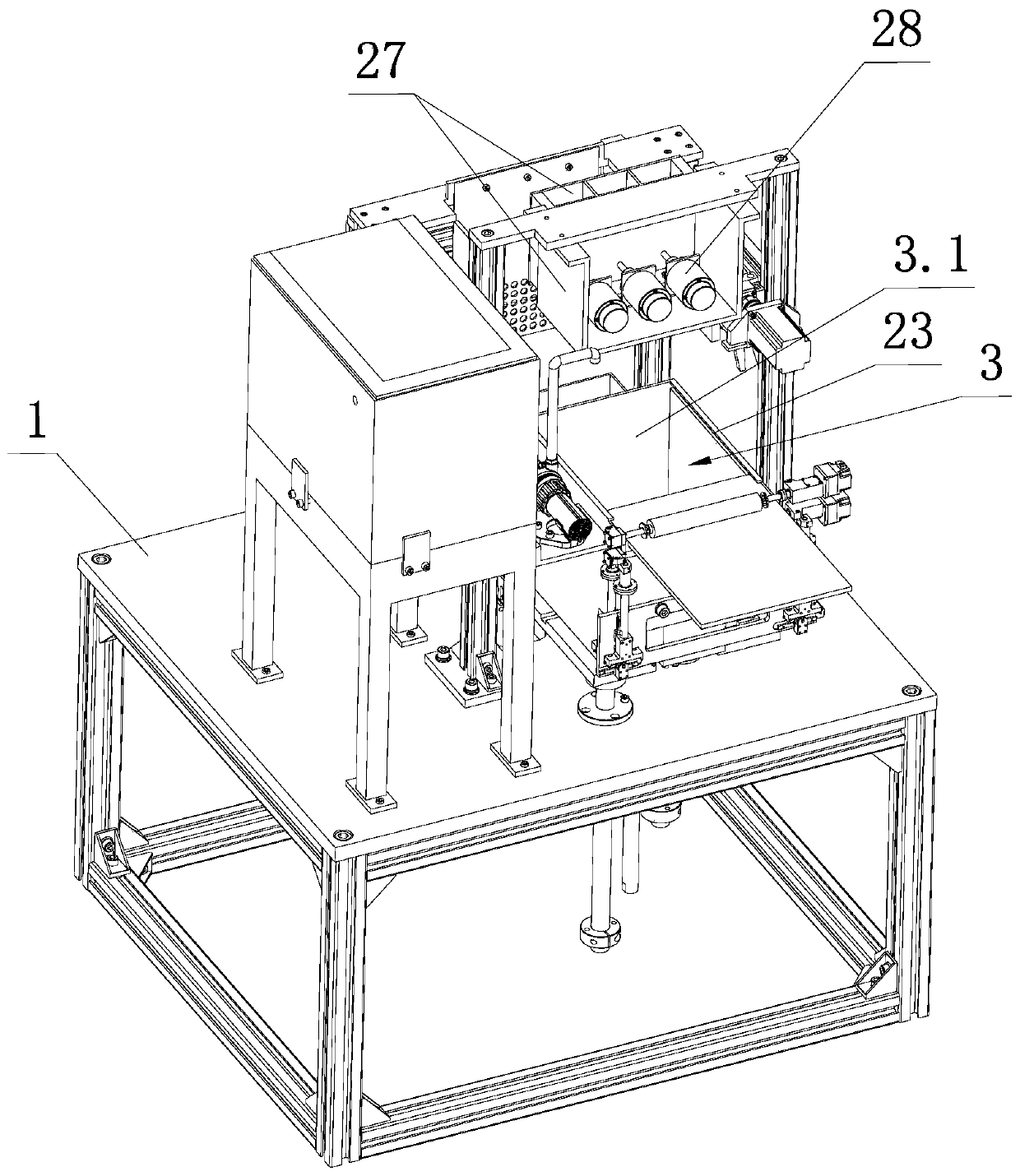

[0028] Such as Figure 1 to Figure 7 Shown, scented tea brewing machine of the present invention, it comprises workbench 1, and workbench 1 is provided with lifting driving pair, and the lifting part of lifting driving pair is provided with soaker 3 that communicates with hot water pipe 2. Specifically, the workbench 1 is rotatably equipped with a vertical first lead screw 6, the workbench 1 is provided with two vertical guide rods 7, the lower surface of the workbench 1 is provided with a second motor 8, and the second motor 8 Connect with the first leading screw 6 through a corner gearbox 9, in other words, the input shaft of the second motor 8 stretches in the corner gearbox 9, and the first leading screw 6 then directly serves as the output shaft of the corner gearbox 9. The bottom of the infuser 3 is provided with a threaded hole and two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com