Processing technology of wild rubus suavissimus

A processing technology, red sweet tea technology, applied in the field of wild red sweet tea processing technology, can solve the problems that cannot meet the consumption trend of safe and healthy tea, increase the bitterness and aftertaste of tea, and the inability of tea to achieve the inner quality aroma, etc., to achieve reduction Grass odor, reducing bitterness and sweetness, good market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

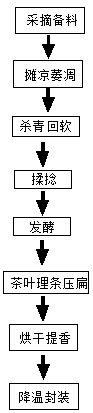

Image

Examples

Embodiment 1

[0018] Embodiment 1: Firstly, wild red sweet tea leaves are picked manually, and one bud and one leaf are selected during picking, and rain leaves, dew leaves, purple bud leaves, and pest and disease bud leaves are not picked when picking. The leaves are 7 cm long and 3 cm wide to ensure the quality of the picked tea leaves, thereby ensuring the quality of the product. The picked red sweet tea leaves are placed in the tea cleaning box and rinsed repeatedly for 3 times, and the cleaning time is 3 minutes each time to ensure the quality of the tea leaves. Cleanliness, take out the washed red sweet tea leaves and place them on a clean water control net to control the moisture, spread the dry red sweet tea leaves on the cooling basket, control the indoor temperature to 24 degrees, and the thickness of the tiles 2 cm to reduce the water content in the red sweet tea leaves to 60%. In order to let the tea leaves emit green air and moisture, and also to improve the quality of the tea l...

Embodiment 2

[0019]Embodiment 2: First, by manually picking wild red sweet tea leaves, one bud and one leaf are selected when picking, and rain leaves, dew leaves, purple bud leaves, and pest and disease bud leaves are not picked when picking. The leaves are 9 cm in length and 3 cm in width to ensure the quality of the picked tea leaves, thereby ensuring the quality of the product. The picked red sweet tea leaves are placed in the tea cleaning box and rinsed repeatedly for 4 times, and the cleaning time is 5 minutes each time to ensure the quality of the tea leaves. Cleanliness, take out the washed red sweet tea leaves and place them on a clean water control net to control the moisture, spread the dry red sweet tea leaves on the cooling basket, control the indoor temperature to 26 degrees, and the thickness of the tiles 3 cm to reduce the water content in the red sweet tea leaves to 66%. In order to let the tea leaves emit green air and moisture, but also to improve the quality of the tea l...

Embodiment 3

[0020] Embodiment three: firstly, wild red sweet tea leaves are picked manually, one bud and one leaf are selected during picking, and rain leaves, dew leaves, purple bud leaves, and pest and disease bud leaves are not picked when picking. The length of the leaves is 10 cm and the width is 4 cm to ensure the quality of the picked tea leaves, so as to ensure the quality of the product. The picked red and sweet tea leaves are placed in the tea cleaning box and rinsed repeatedly for 5 times, and each cleaning time is 10 minutes to ensure the quality of the tea leaves. Cleanliness, take out the washed red sweet tea leaves and place them on a clean water control net to control the moisture, spread the dry red sweet tea leaves on the cooling basket, control the indoor temperature to 30 degrees, and the thickness of the tiles 4 cm to reduce the water content in the red sweet tea leaves to 65%. In order to let the tea leaves emit greenness and moisture, and also to improve the quality ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com