Marine electromechanical equipment virtual test application service system and method

A virtual test and electromechanical equipment technology, applied in special data processing applications, design optimization/simulation, geometric CAD, etc., can solve problems such as huge labor costs, high test costs, etc., to reduce repetitive work, reduce the number of physical tests, The effect of reducing production cycle and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

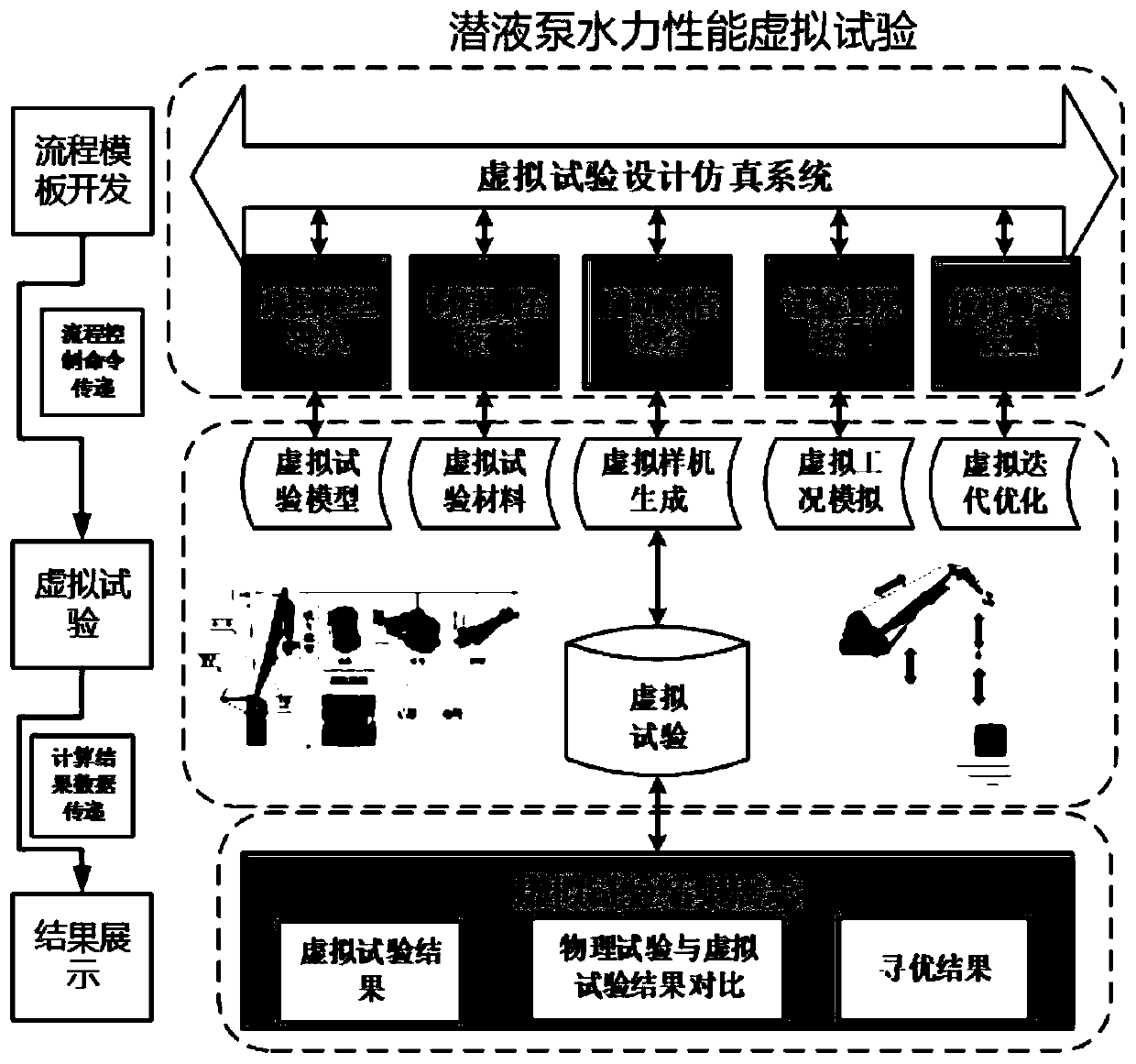

[0049] The implementation steps of the hydraulic performance of the submersible pump: enter the virtual test module of the hydraulic performance of the submersible pump through the portal system, use the general finite element software Ansys as the platform, and go through the following steps:

[0050] (1) Virtual test calculation management. In the virtual test interface, the user first needs to select the working directory, and all the completed submersible pump hydraulic performance virtual test tasks in the table are automatically updated in the table, and each subsequent virtual test task is placed in the Under this directory, it also serves as the homepage of the virtual test of the hydraulic performance of the submersible pump;

[0051] (2) Test bench model import. In the test bench model import interface, it supports the function of importing the local model of the test bench and the import function of the database model of the test bench. On the premise of importing th...

Embodiment 2

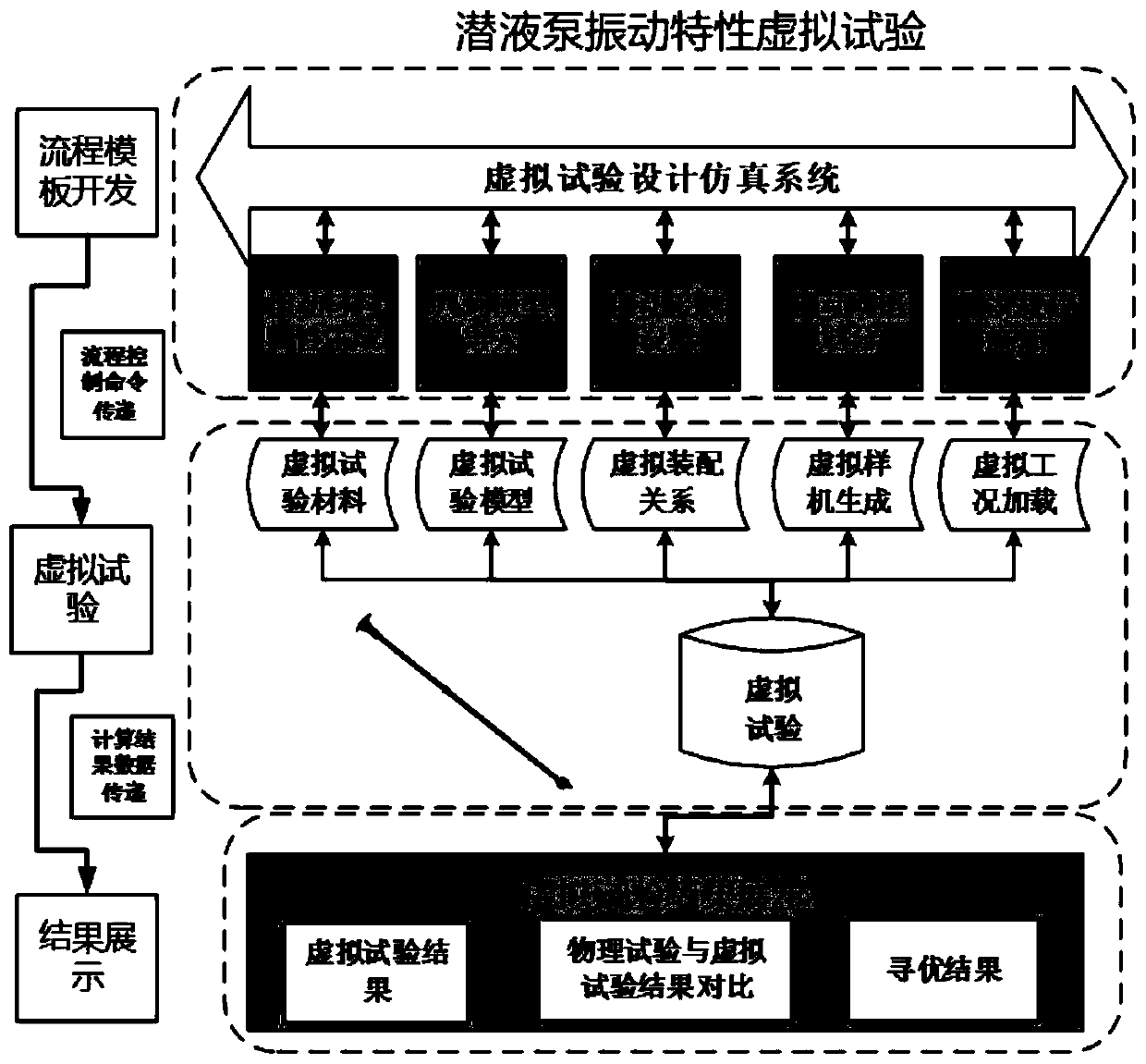

[0062] The implementation steps of the vibration performance of the submersible pump: use the general finite element software Ansys workbench as the platform, import the submersible pump model (including roof, pipe string, pump head and other components) in the DesignModel module, and check the material density, Yang Modulus and other parameters are modified. Tolerances between parts are adjusted through manual contact settings. Set the mesh size between different parts to discretize the submersible pump model. According to the mechanical characteristics of the crane, the boundary constraints and load addition are carried out, so as to establish the final vibration simulation model of the submersible pump.

Embodiment 4

[0064] The implementation steps of STC valve speed regulation performance of submersible pump: enter the process interface, select the working path and create a new virtual test; use the multi-field general CAE platform MWorks as the calculation platform, import the STC valve model required for this calculation from the local or database; Modify the control parameters and save them, set the sweeping parameters and solution parameters, and then start the calculation program; add the physical test data after the calculation is completed, check and compare the data and result curves of this virtual test; analyze the error of this virtual test and Give an evaluation, if the error is large, you can choose to modify the parameters and recalculate; view the final result curve and generate a report.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com