Electronic detonator leg wire tail end connecting device and electronic detonator

An electronic detonator and connecting device technology, which is applied to weapon accessories, fuzes, offensive equipment, etc., can solve problems such as the inability to achieve the set blasting shape and directional blasting, the inability to achieve the blasting shape, the blasting directional target, and the unreliable connection. , to maintain integrity and stability, good waterproof and rainproof functions, and ensure accurate and controllable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

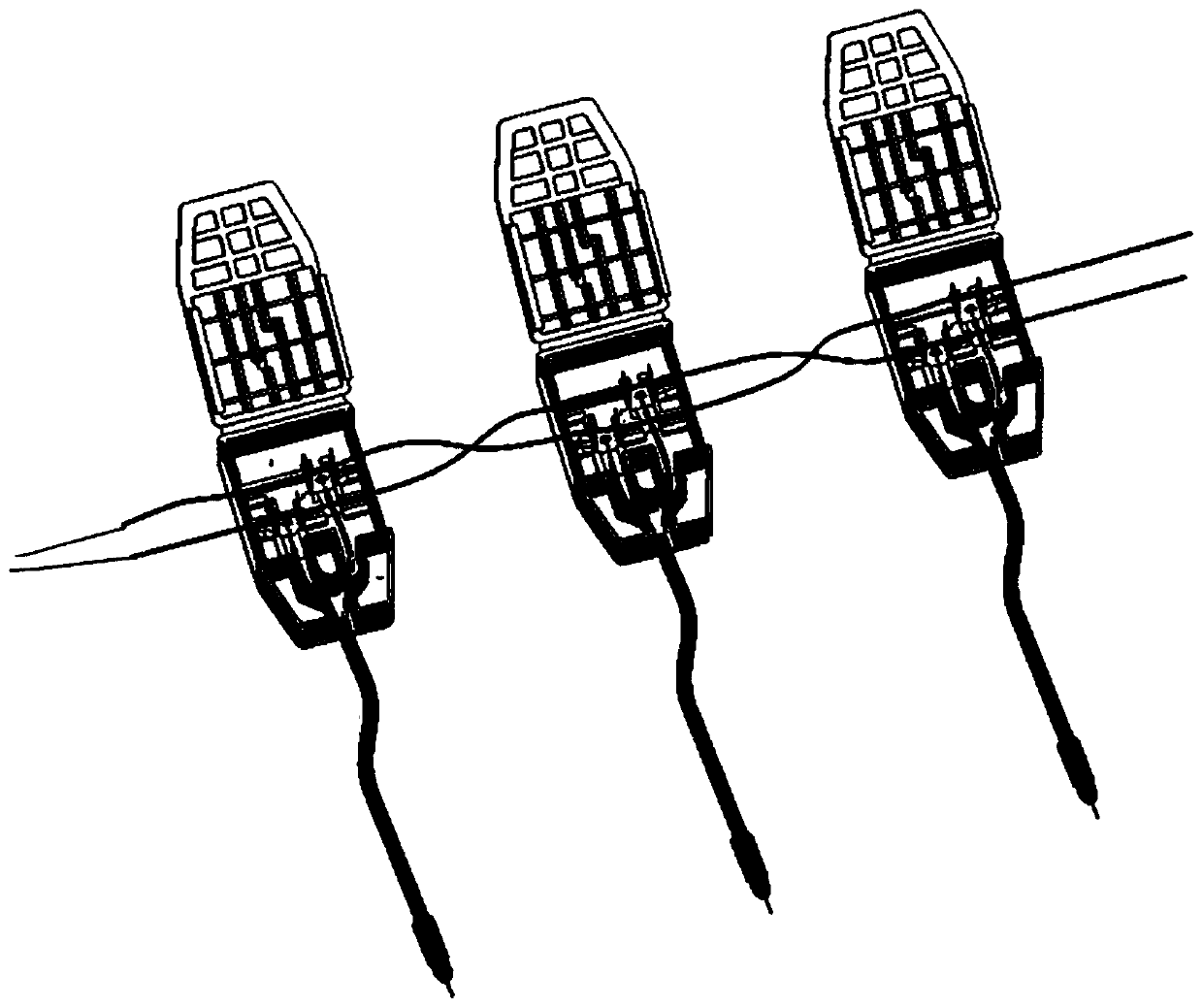

[0038] Embodiment 1: as figure 2 , 3 As shown in , 4, the connecting device at the end of the electronic detonator foot wire includes two sections of detachable male-female butt joints that are mutually detachable. Connecting parts, the male plug-in 1 and the female plug-in 2 can conduct a circuit after being plugged and connected, the male plug-in 1 is connected to the detonating bus 5, and the female plug-in 2 is connected to another section of the detonating bus 5 and the detonator foot wire 4, Both the male plug 1 and the female plug are integrally formed adapters, and the interior is sealed and waterproof after docking. One end of the detonating busbar 5 is connected to the detonator, and the rest of the detonating busbar 5 is divided into several sections and connected between the female plug-in 2 and the male plug-in 1 in turn to form a complete detonating busbar 5. One parallel connection is connected to each electronic detonator, and the electronic detonator is con...

Embodiment 2

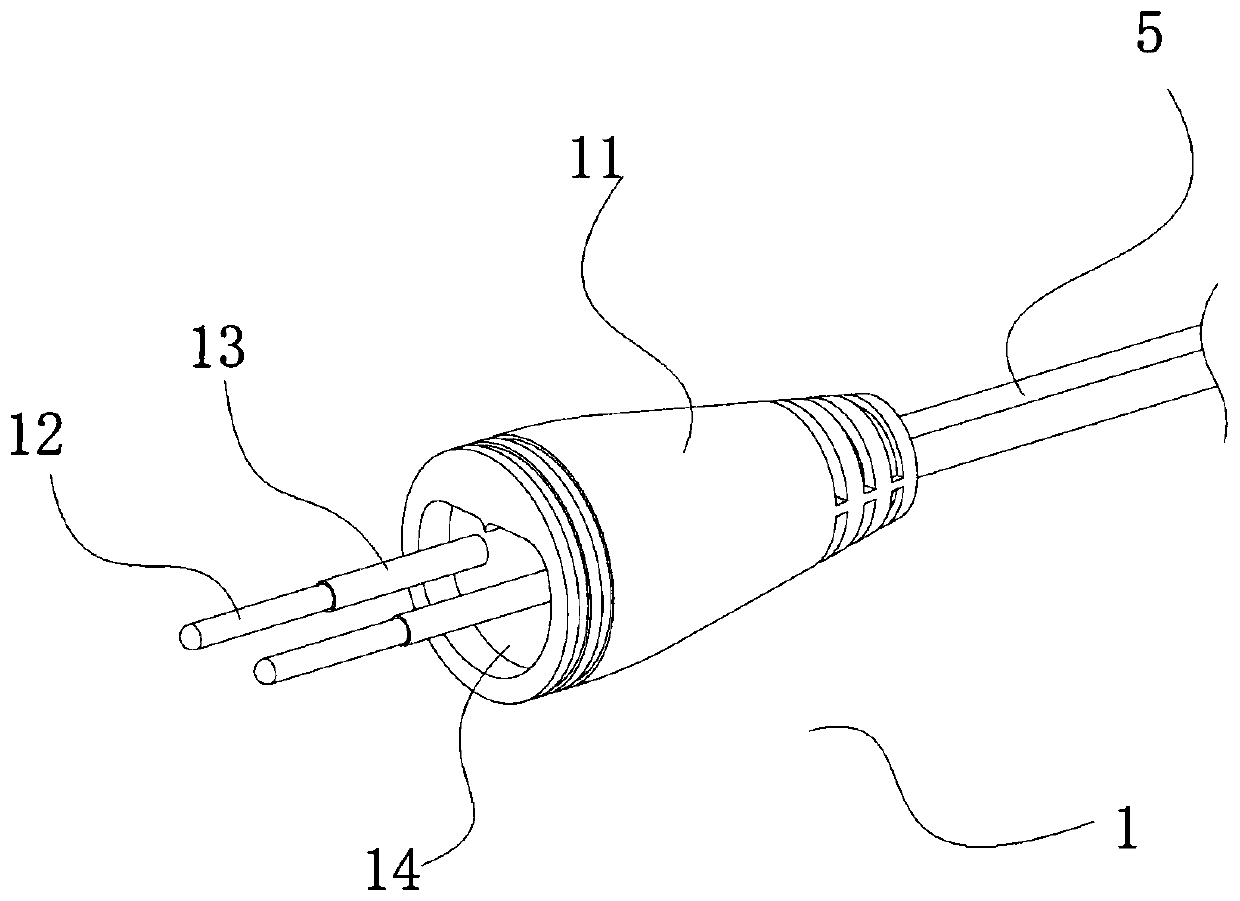

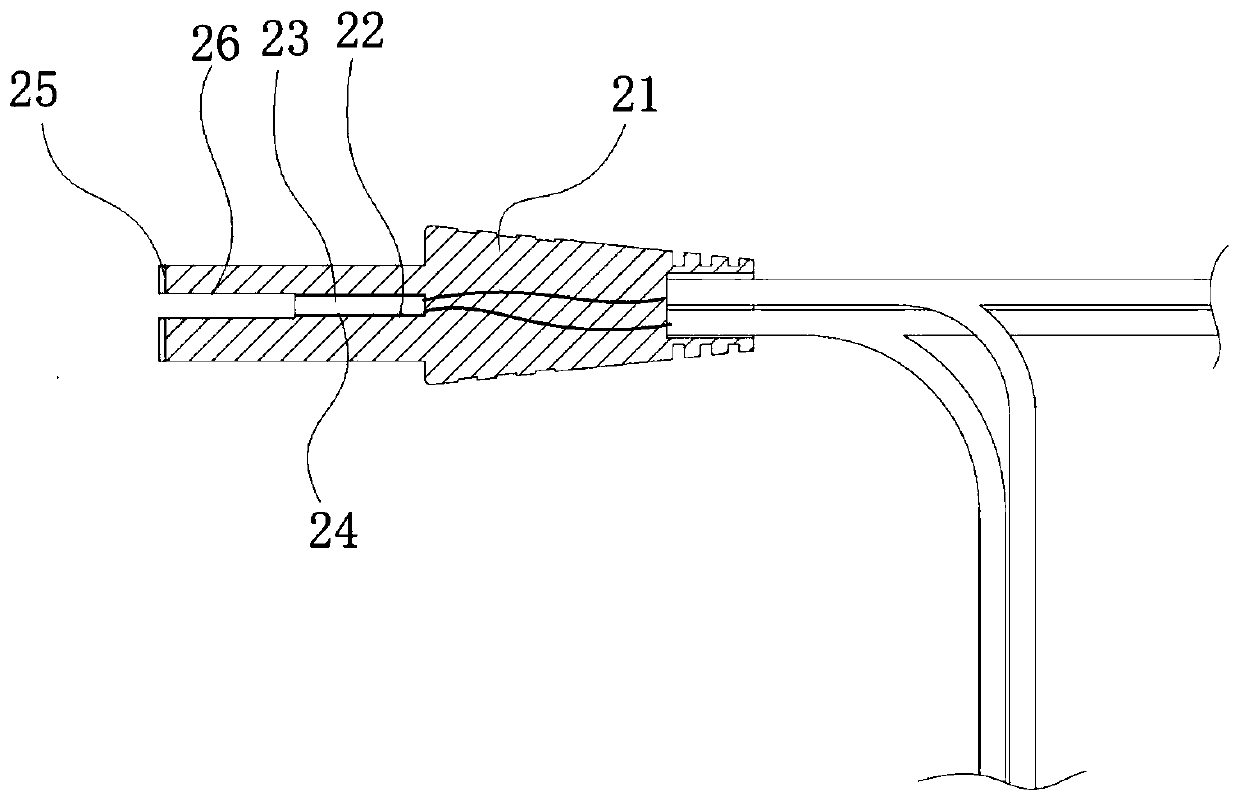

[0039] Embodiment 2: On the basis of Embodiment 1, preferably, the male connector 1 includes a body 11, two pins 12 located at the end of the body 11, and each pin is conductively transmitted to the two electrode wires of the detonating bus 5; The roots of the pins 12 are all wrapped with a layer of waterproof coating or waterproof cover 13; the female plug-in 2 includes a female plug body 21, and two sections are opened in the female plug body 21 to fit the slots 23 of the pins 12. , the slot 23 is provided with a contact ring 24 for contacting with the pin 12, the contact ring 24 is connected to the line electrode 22 built in the female plug body 21, and the line electrode 22 is connected to a group of detonating bus bars 5; The outer end face portion of the slot 23 is partially coated with a waterproof coating or a waterproof ring 25 . In actual use, hold the main body 11, align the pins 12 with the slots 23 on the female plug body 21 of the female plug 2, insert the pins 1...

Embodiment 3

[0041] Embodiment 3: On the basis of Embodiments 1 and 2, the easy-to-fall male and female butt connectors are formed of PVC material as a whole. The body 11 of the male connector 1 has no pins 12, and there is only one dual-circuit plug 3, which is compatible with the earphone plug. The hole structure is similar. The dual circuit plug 3 includes a second contact segment 32 at the root and a first plug segment 31 at the end. The junction between the second contact segment 32 and the first plug segment 31 is insulated Layers are separated; and the female plug body 21 of the female plug-in 2 has only one section of jack 33 that is compatible with the dual-circuit plug 3, and the jack 33 includes two sections of contact sections, which are sequentially from outside to inside The second contact section 35 and the first contact section 34 are separated by an insulating layer and connected to the detonating bus bar 5 and the detonator leg 4 respectively. After connection, the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com