Engine balance shaft assembly and engine

A technology for balancing shafts and engines, applied in the field of vehicle parts, can solve the problems of occupying engine space, inconvenient engine layout, complicated crankshaft structure, etc., and achieves the effects of good oil pumping effect, simple structure and simplified layout.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

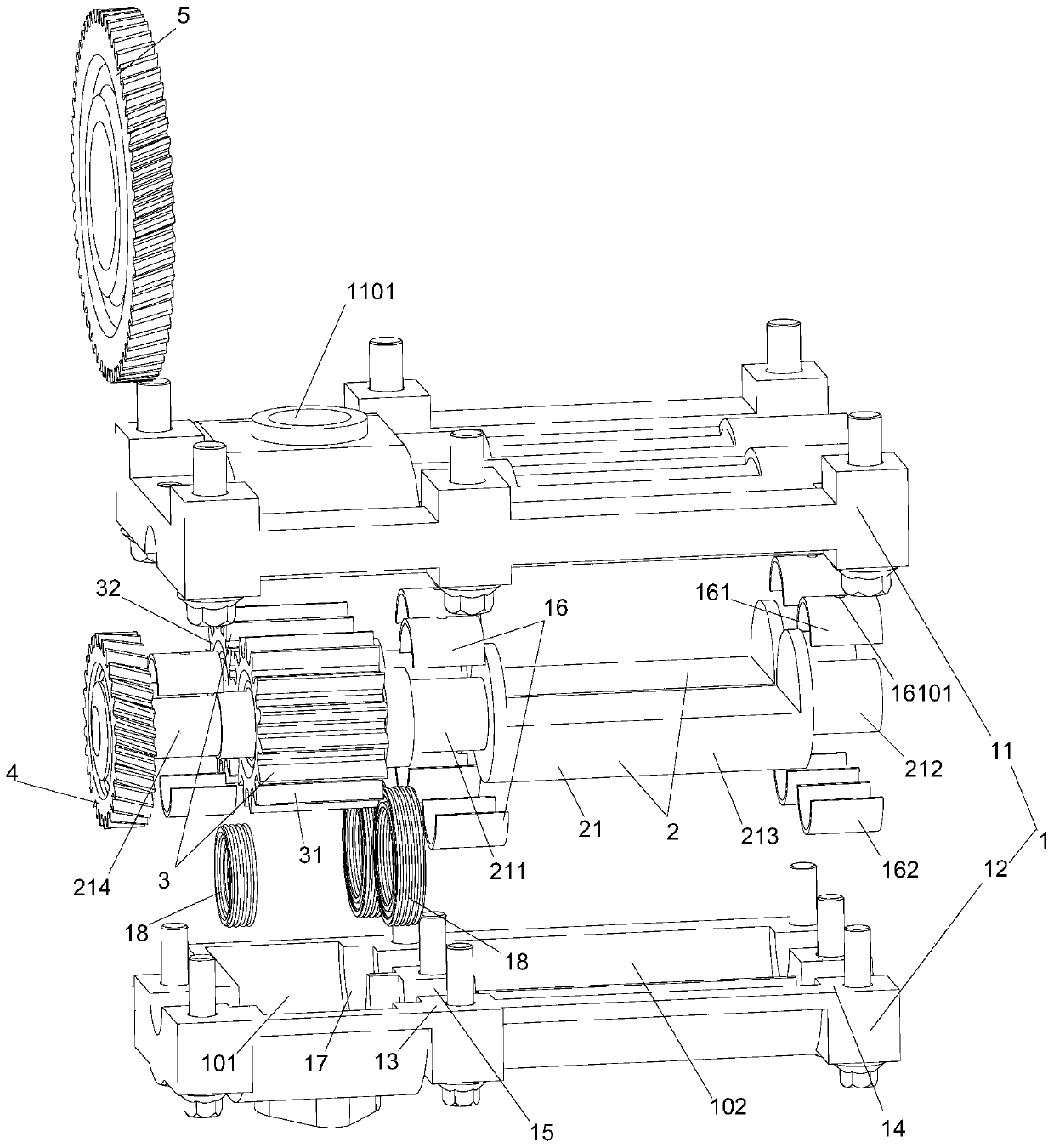

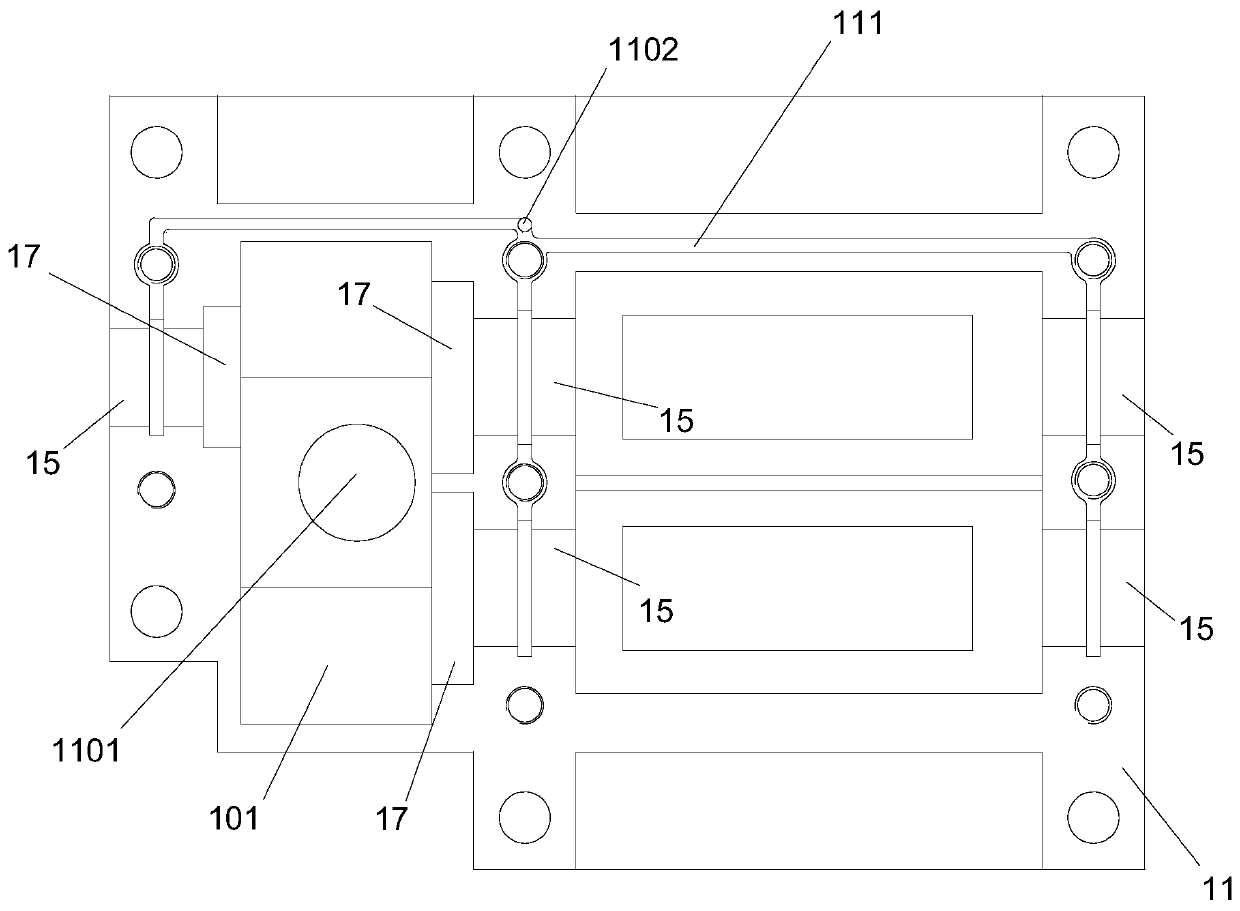

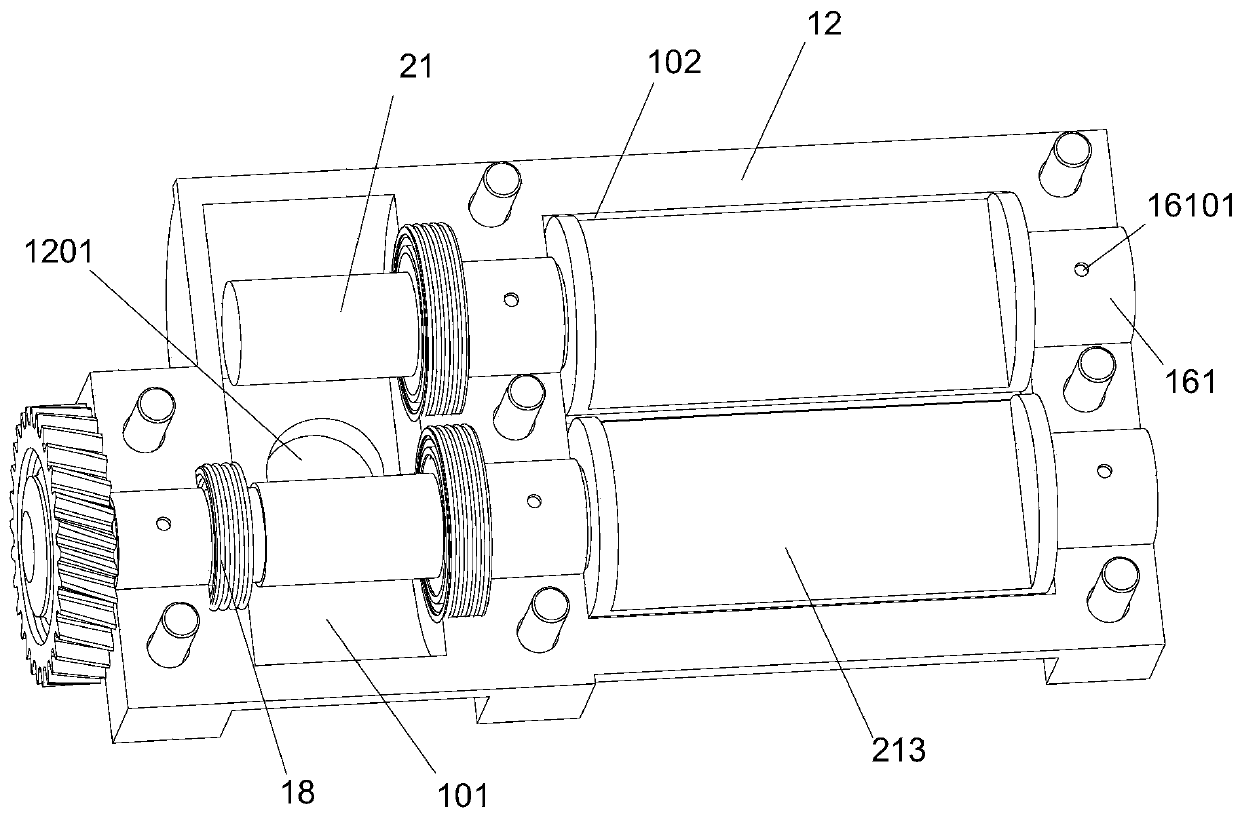

[0036] This embodiment relates to an engine balance shaft assembly, which includes a housing 1 with a first cavity 101 and a balance shaft with two balance shafts 21 rotatably supported on the housing 1 component2. In addition, the engine balance shaft assembly also includes a linkage assembly 3 located in the first cavity 101 to form a synchronous rotation of the two balance shafts 21, and the linkage assembly 3 can also form an oil collection device for oil from the engine cylinder For pumping into the oil channel on the engine block, in addition to the above structure, the engine balance shaft assembly also includes a transmission member 4 for inputting power to the engine balance shaft assembly.

[0037] Based on the above overall structure, a preferred structure of the housing 1 is as follows figure 1 As shown, it specifically includes an upper casing 11 and a lower casing 12, and opposite grooves are configured on the upper casing 11 and the lower casing 12, and the abo...

Embodiment 2

[0051] This embodiment relates to an engine, and the engine balance shaft assembly as described in Embodiment 1 is installed on the engine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com