Printing and packaging wastewater treatment process

A wastewater treatment, printing and packaging technology, applied in water/sewage treatment, biological water/sewage treatment, flotation water/sewage treatment, etc., can solve the problems of industrial wastewater biochemical tail water not meeting discharge standards, water environment hazards, ecological problems, etc. To solve the problems of high toxicity, to achieve the effect of increasing the sludge age, high volume load, and improving the treatment capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

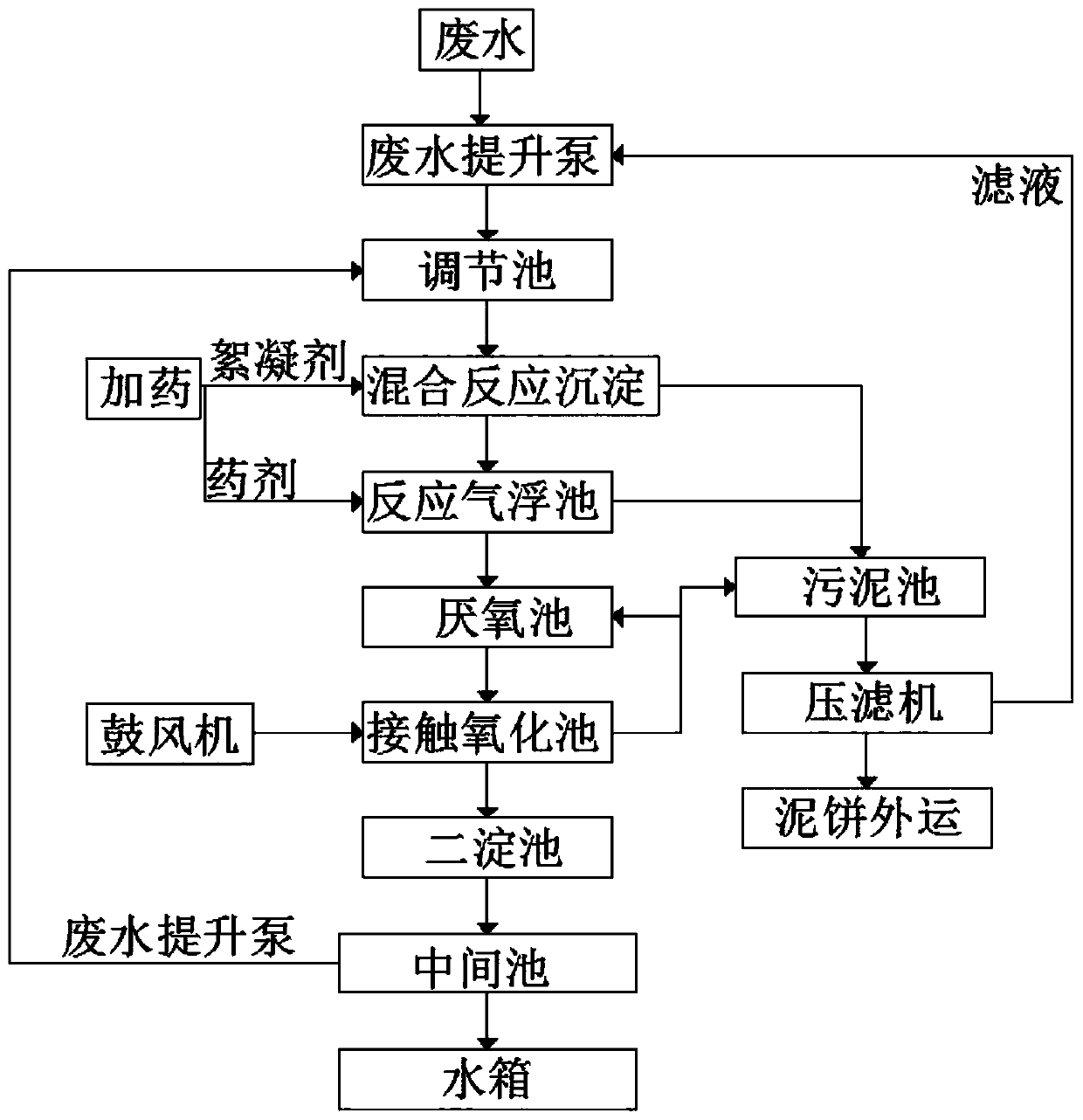

[0032] A printing and packaging wastewater treatment process, comprising the following steps:

[0033] (1) The wastewater from the workshop is directly discharged into the sump, and then automatically sent to the sewage treatment regulating tank according to the liquid level. The air mixing system fully mixes the wastewater in the regulating tank to achieve a state of homogeneity and quantity;

[0034] (2) The wastewater is transported from the adjustment tank to the mixed reaction sedimentation tank through the wastewater lifting pump, and flocculant is added to the mixed reaction sedimentation tank, so that the SS and oily substances in the wastewater undergo coagulation and flocculation reactions, thereby transforming into easy The precipitated large-grained alum flowers separate the solid pollutants from the wastewater, and the sludge separated from the reaction sedimentation tank is discharged into the sludge tank;

[0035] (3) Lift the wastewater to the air flotation rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com