A corrugated steel web bridge asynchronous hanging basket

A corrugated steel web and asynchronous technology, which is applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of low installation efficiency of corrugated steel webs, shorten the length of the tower crane boom, shorten the occupation time of the tower crane, etc., and achieve shortening The effect of boom length, improving construction efficiency, and reducing the demand for hoisting energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

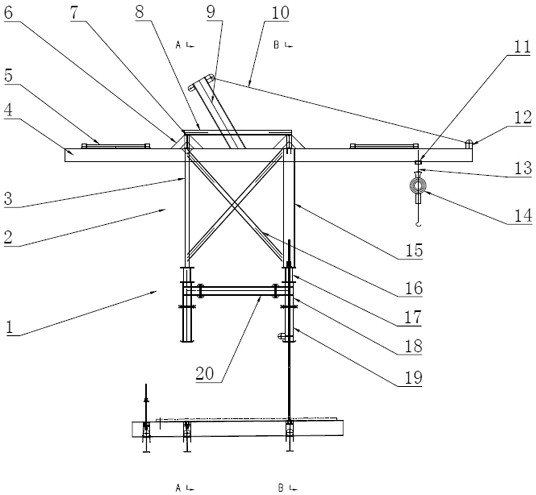

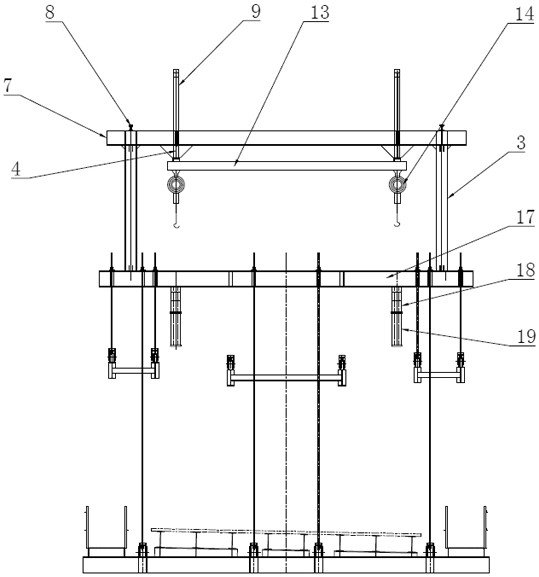

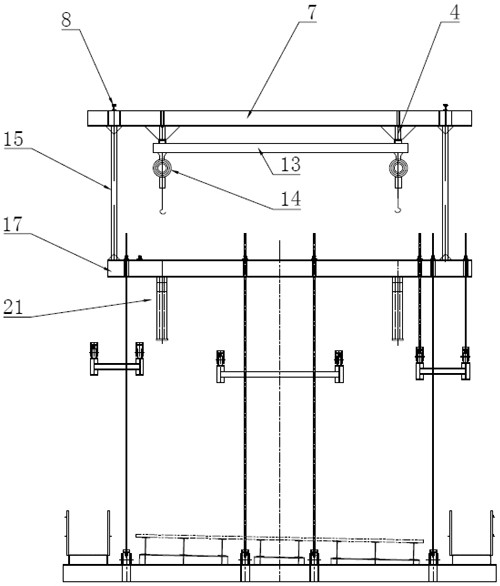

[0033] like figure 1 figure 2 image 3 Figure 4 As shown, an asynchronous hanging basket for a corrugated steel web bridge includes a movable support lower layer 1 fixed to each other and a corrugated steel web lifting upper layer 2. The height of the movable support lower layer is limited to the minimum height required for the construction of the corrugated steel web bridge roof, and The height of the upper layer of the web hoisting is limited to the minimum height required for the horizontal translation of the corrugated steel web.

[0034] Wherein, the movable support lower layer includes four legs 21 supported in the corrugated steel web upper wing perforated steel plate grooves, two lower beams 17 connecting the legs horizontally and two parallel lower longitudinal beams 20 connecting the legs vertically. The corrugated steel web hoisting upper layer includes four columns vertically and fixedly connected to the two lower beams, two upper main beams 7 connected horizo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com