Fire-fighting pipeline transportation device

A technology for transporting devices and fire-fighting pipes, applied in the directions of transport and packaging, single-axle trolleys, trolley accessories, etc., can solve problems such as danger and disengagement, and achieve the effect of avoiding pipe material movement and increasing the effective bearing area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

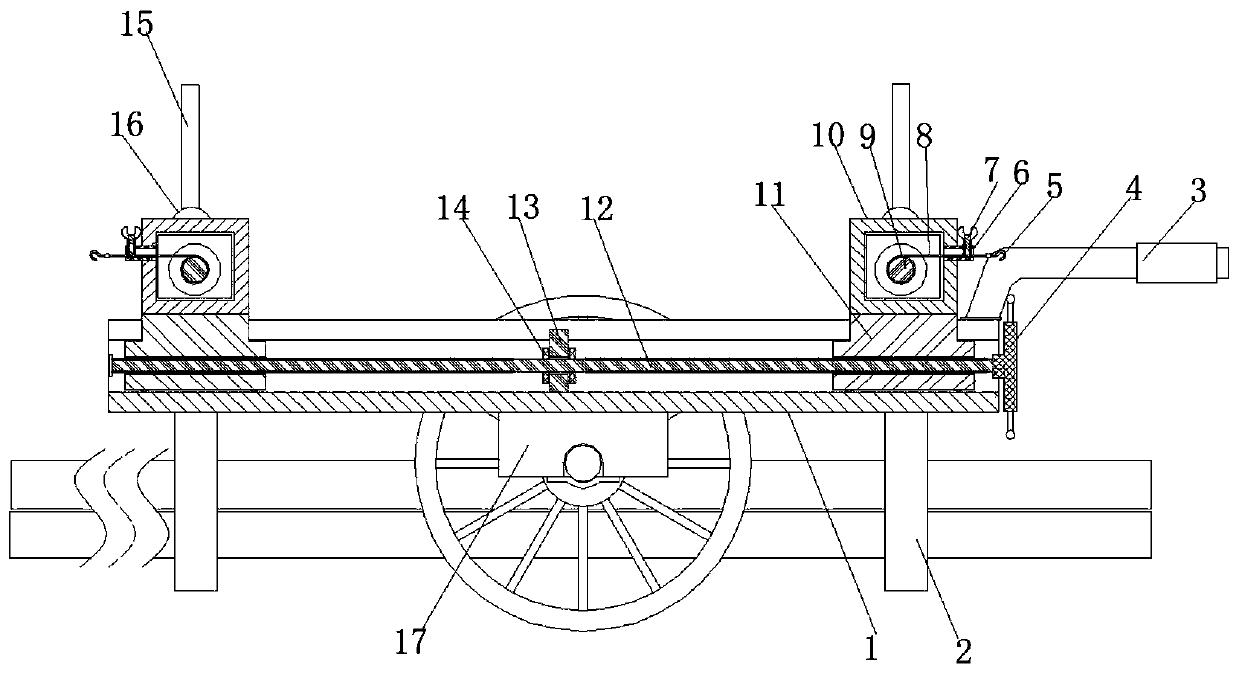

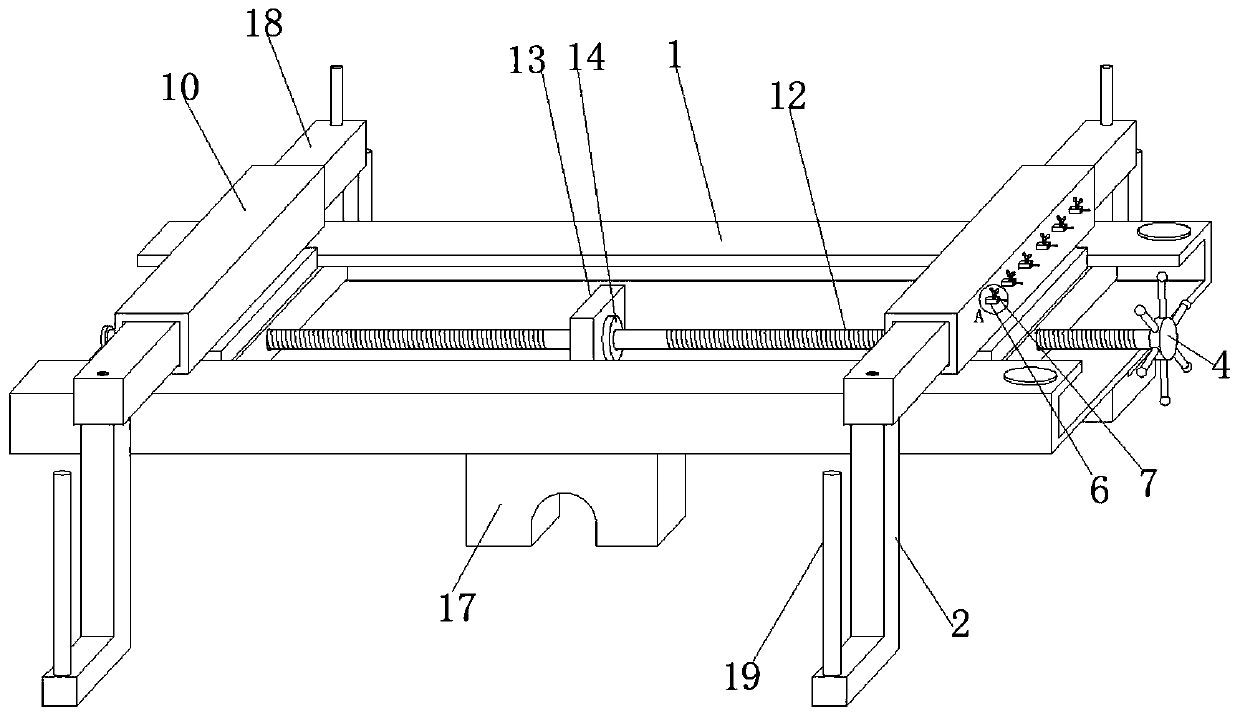

[0029] refer to Figure 1-5 , a fire pipeline transportation device, comprising a trolley base 1 with an upward opening in a C-shaped steel structure, T-shaped sliders 11 are slidably connected to the bottom of the trolley base 1 near both ends, and one of the two T-shaped sliders 11 is opposite to each other. There are coaxially distributed screw holes with opposite thread directions on the side near the middle. The same stud 12 is screwed in the two screw holes. A baffle 13 is fixed in the middle of the bottom of the trolley base 1, and the stud The two ends of the peripheral outer wall of 12 near the baffle plate 13 are all fixed with annular retaining rings 14, and the tops of the two T-shaped sliders 11 are fixed with horizontal tubes 10 by bolts, and the two ends of the horizontal tubes 10 are all inserted with extension rods. 18, and the lower surface of the end of the extension rod 18 is fixed with a support bar 2 of L-shaped structure, and the upper surface end of the...

Embodiment 2

[0038] refer to figure 2 and Figure 5 , a fire-fighting pipeline transportation device. Compared with Embodiment 1, this embodiment also includes that the bottom end of the support rod 2 can also be set as a groove-shaped slide rail 20-shaped structure with the opening upward, and the groove bottom of the groove-shaped slide rail 20 A slide block 24 is slidably connected to the end far away from the support bar 2 , a tension spring 21 is arranged between the outer wall of the slide block 24 and the outer wall of the support bar 2 , and the limit gear bar 19 is fixed on the top of the slide block 24 .

[0039] Wherein, two limiting holes 23 are formed at the end of the groove bottom of the grooved slide rail 20 away from the supporting rod 2 , and the limiting rods 22 are inserted into the two limiting holes 23 .

[0040] When a wider pipe body needs to be placed during use, first pull out the limit rod 22 at the bottom of the groove, and then the pipe body can be clamped be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com