Automatic powder spraying method and system

A powder spraying and automatic technology, applied in general control system, control/adjustment system, spraying device, etc., can solve the problems of low spraying efficiency, relying on manual operation, and inability to automatically switch toner, and achieve uniform spraying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

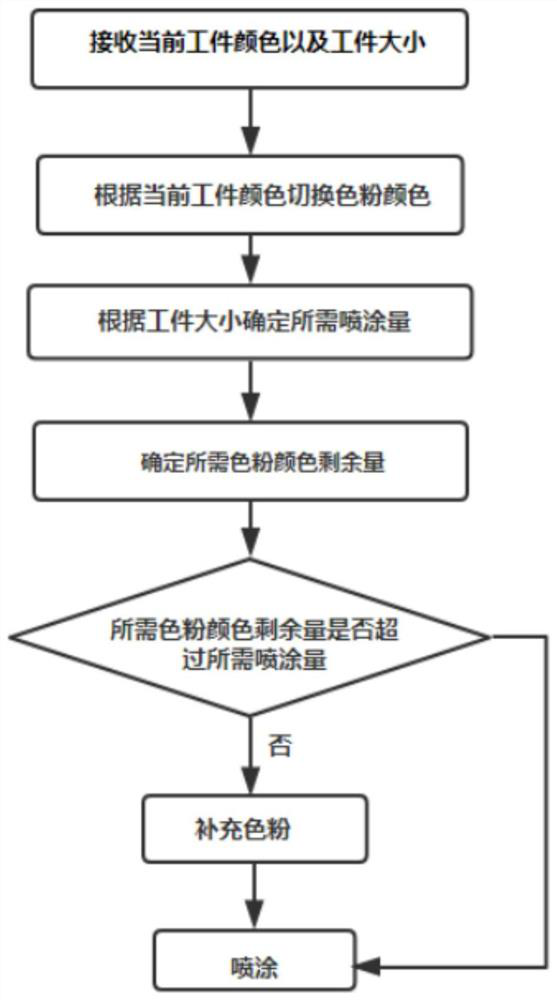

[0046] Embodiment 1: as figure 1 As shown, the present invention provides a kind of automatic powder spraying method, is used for automatic powder spraying system, comprises:

[0047] Receive the current workpiece color and workpiece size;

[0048] Switch the toner color according to the current workpiece color;

[0049] Determine the required spraying amount according to the size of the workpiece;

[0050] Determine the remaining amount of the required toner color, and check whether the remaining amount of the required toner color exceeds the required spraying amount, if it exceeds, then spray, if not, then replenish the required toner and then spray.

Embodiment 2

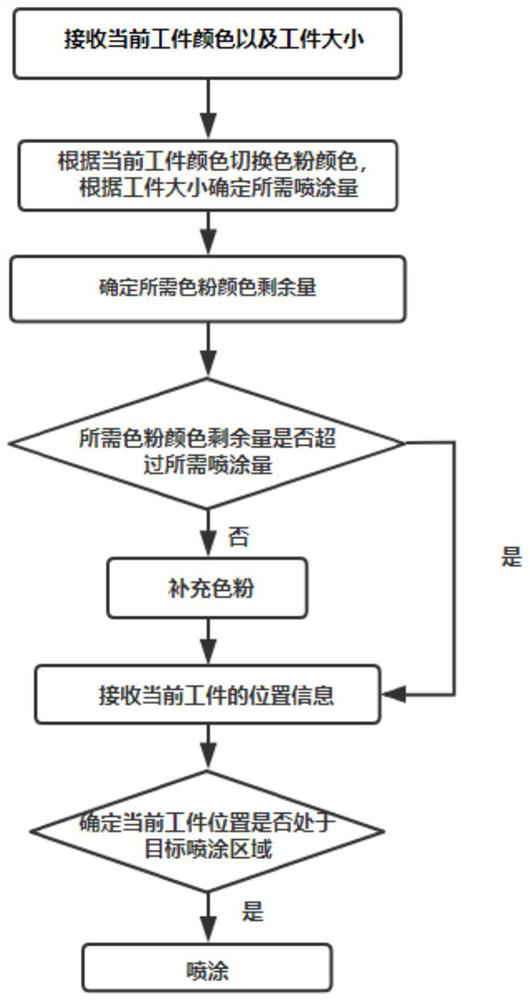

[0051] Embodiment 2: as figure 2 As shown, the present invention provides a kind of automatic powder spraying method, is used for automatic powder spraying system, comprises:

[0052] Receive the current workpiece color and workpiece size;

[0053] Switch the toner color according to the current workpiece color;

[0054]Determine the required spraying amount according to the size of the workpiece;

[0055] Determine the remaining amount of the required toner color, and whether the remaining amount of the required toner color exceeds the required spraying amount, if not, replenish the required toner;

[0056] If it exceeds, receive the position information of the current workpiece;

[0057] It is determined whether the position of the current workpiece is in the target spraying area, and if it is not in the target spraying area, the conveying assembly moves the position of the current workpiece until it is in the target spraying area and then sprays.

Embodiment 3

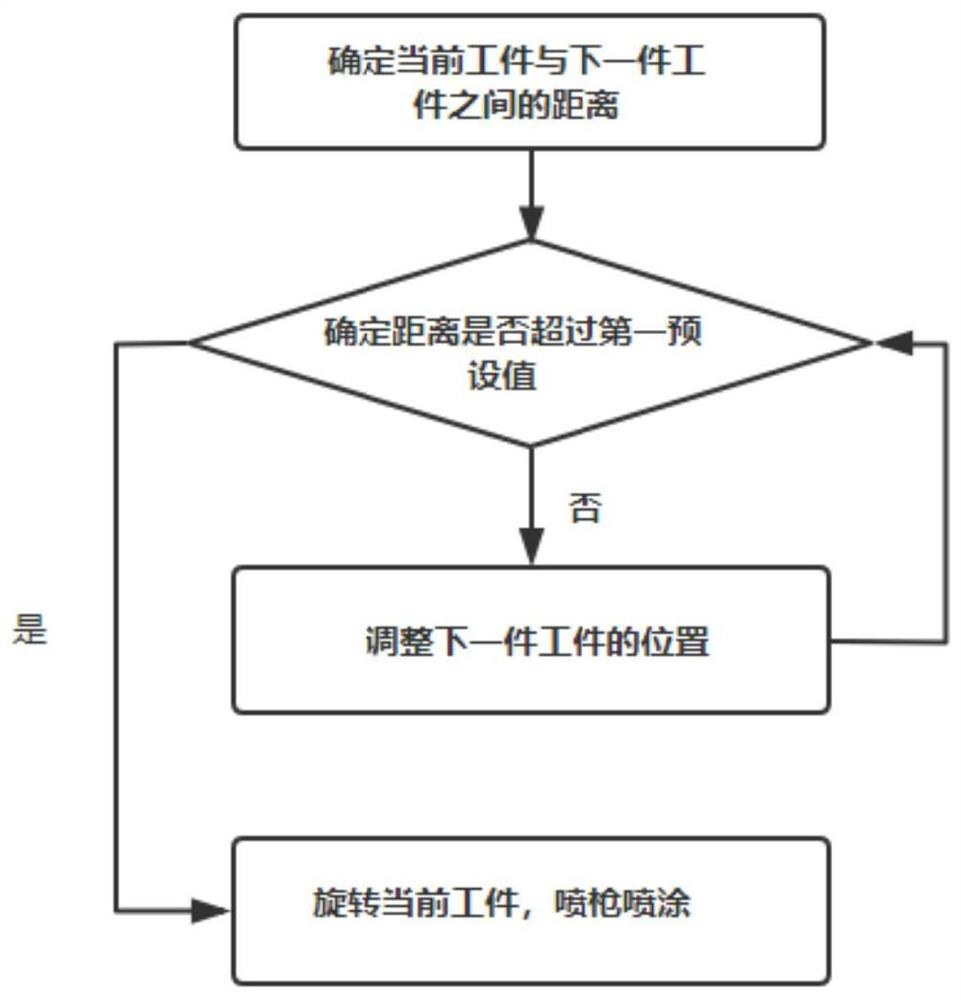

[0058] Embodiment 3: as image 3 As shown, the present invention provides a kind of automatic powder spraying method, is used for automatic powder spraying system, comprises:

[0059] Receive the current workpiece color and workpiece size;

[0060] Switch the toner color according to the current workpiece color;

[0061] Determine the required spraying amount according to the size of the workpiece;

[0062] Determine the remaining amount of the required toner color, and whether the remaining amount of the required toner color exceeds the required spraying amount, if not, replenish the required toner;

[0063] If it exceeds, receive the position information of the current workpiece;

[0064] Determine whether the position of the current workpiece is in the target spraying area, if it is not in the target spraying area, then the conveying assembly moves the position of the current workpiece until it is in the target spraying area;

[0065] Determine whether the distance betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com