Ice cream stick loading device

An ice cream stick and material wheel technology, applied in the directions of loading/unloading, transportation and packaging, conveyors, etc., can solve the problems of more manual participation, difficulty in automatic control, and congestion in feeding, and achieve the effect of preventing excessive accumulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

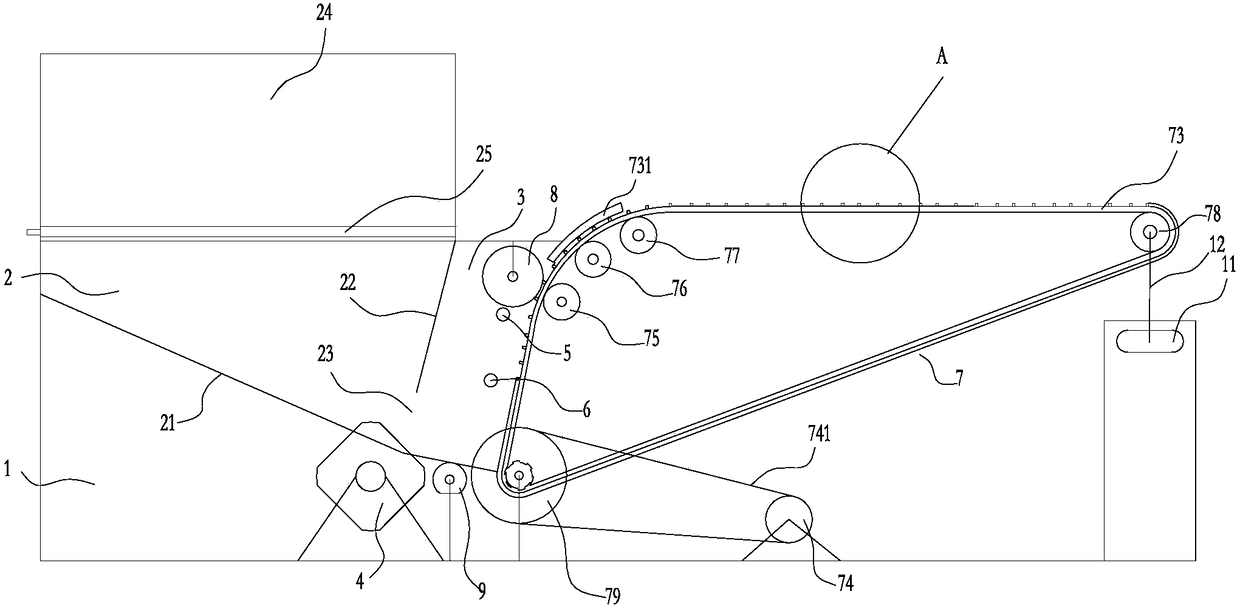

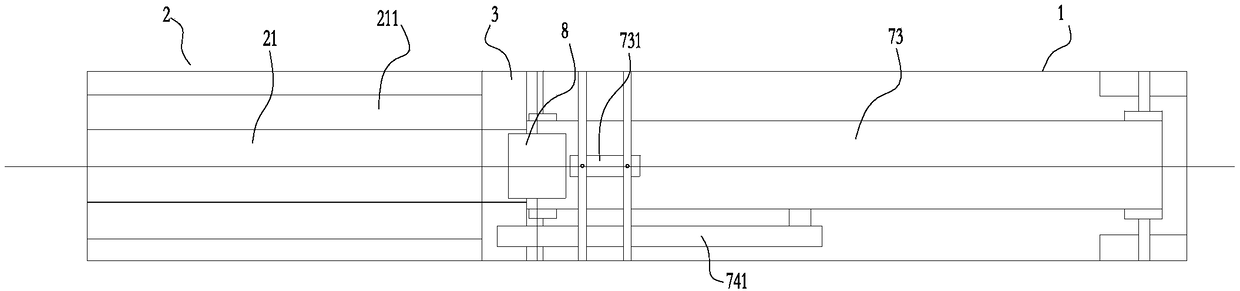

[0038] Such as Figure 1-Figure 3 As shown, an ice cream stick feeding device includes a frame 1 and a first hopper storehouse 2, a second hopper storehouse 3, a position detection assembly, a dial wheel 4, and a belt transmission mechanism all installed on the frame 1. 7 and the controller; the bottoms of the first hopper storehouse 2 and the second hopper storehouse 3 communicate, and the second hopper storehouse 3 is located between the first hopper storehouse 2 and the belt transmission mechanism 7;

[0039] A part of the conveyor belt 73 of the belt conveyor mechanism 7 is obliquely arranged in the second hopper bin 3 and transports the ice cream sticks in the second hopper bin 3 upward;

[0040] The shifting wheel 4 is installed at the outlet 23 of the first hopper bin 2 and transfers the ice cream sticks at the outlet 23 of the first hopper bin 2 into the second hopper bin 3;

[0041] The position detection component is installed on one side of the second hopper wareho...

Embodiment 2

[0045] Such as Figure 1-Figure 3As shown, in addition to having the technical features of Embodiment 1, the ice cream stick feeding device of this embodiment includes a high-level monitoring sensor 5 and a low-level monitoring sensor 6, and the high-level monitoring sensor 5 is installed on the The top of the low-level monitoring sensor 6; the high-level monitoring sensor 5 and the low-level sensor 6 are all used to monitor the amount of ice cream sticks in the second hopper warehouse 3, which is actually monitoring the stacking height of the ice cream sticks in the second hopper warehouse 3;

[0046] When the stacking height of the ice cream sticks is lower than the position of the low position monitoring sensor 6, the controller controls the setting wheel 4 to start picking; 5 position, the controller controls the dial wheel 4 to stop dialing.

[0047] Two monitoring sensors arranged up and down are arranged in the second hopper bin 2. The low-level monitoring sensor 6 and...

Embodiment 3

[0050] Such as Figure 1-Figure 3 As shown, on the basis of Embodiment 2 and / or Embodiment 1, the ice cream stick feeding device of this embodiment also includes a monitoring double material wheel 8, and the monitoring double material wheel 8 is installed on the inside of the second hopper warehouse 3 On the wall and above the position detection assembly, the peripheral side of the monitoring double material wheel 8 is set close to the conveyor belt 73 and is tangent to the conveying direction of the conveyor belt 73; The running direction is vertical, and the monitoring double material wheel 8 is set close to the conveyor belt 73;

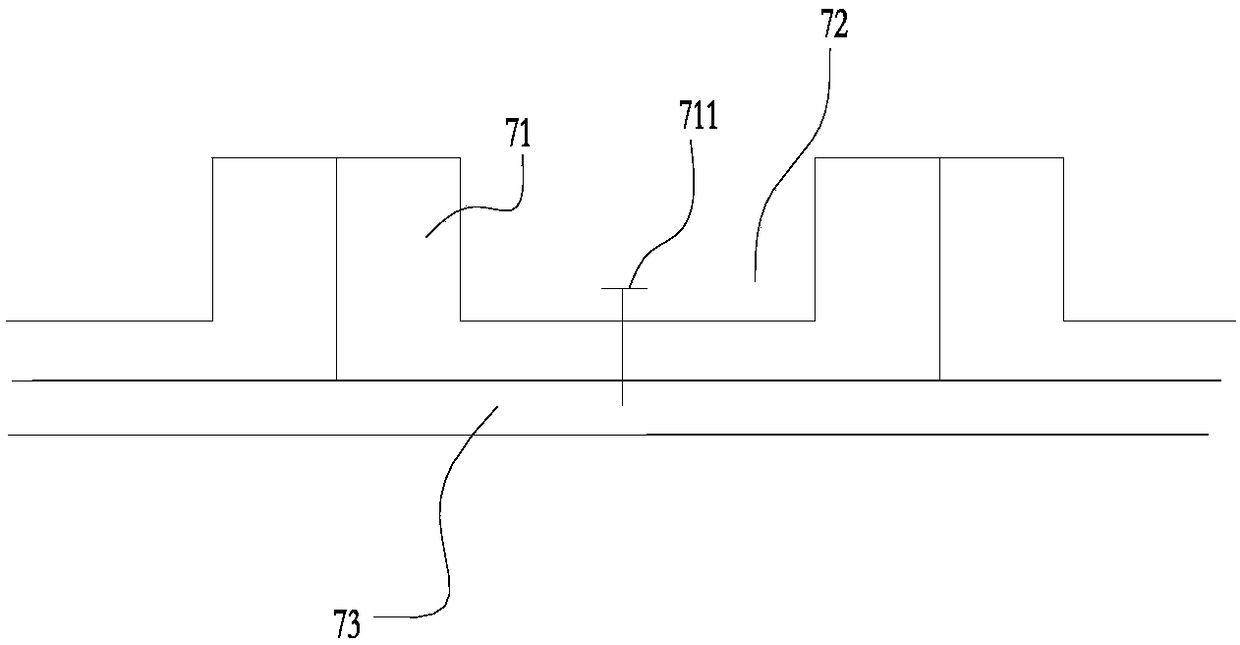

[0051] Such as Figure 1-Figure 3 As shown, the conveyor belt 73 of the present embodiment is provided with a number of feeding troughs 72 with open ends, and the feeding troughs 72 are arranged perpendicular to the conveying direction of the conveyor belt 73. It is suitable for the thickness of the ice cream stick; the monitoring double materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com