Aggregate crushing and conveying device for construction

A conveying device and construction technology, applied in the field of construction processing, can solve the problems of multi-stage crushing and screening of difficult aggregates, uneven crushing of aggregates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

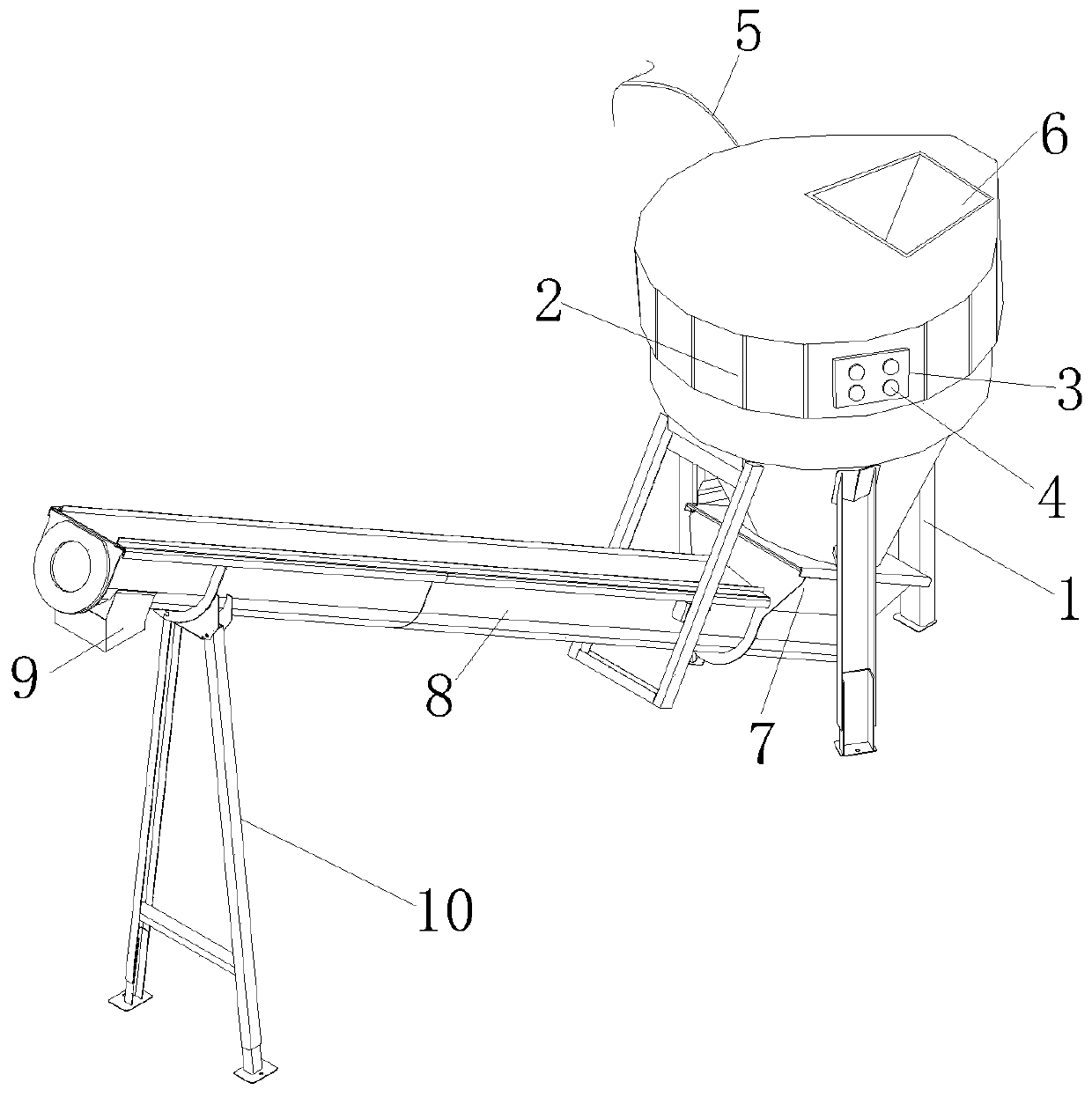

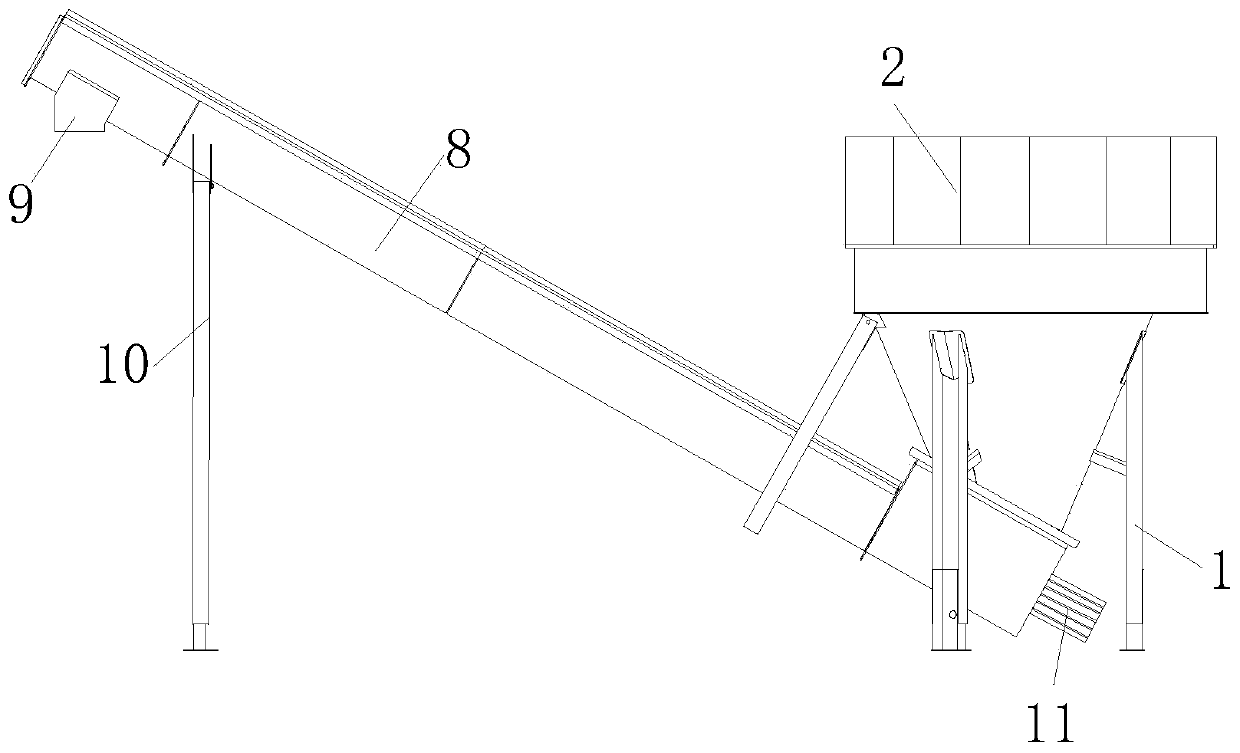

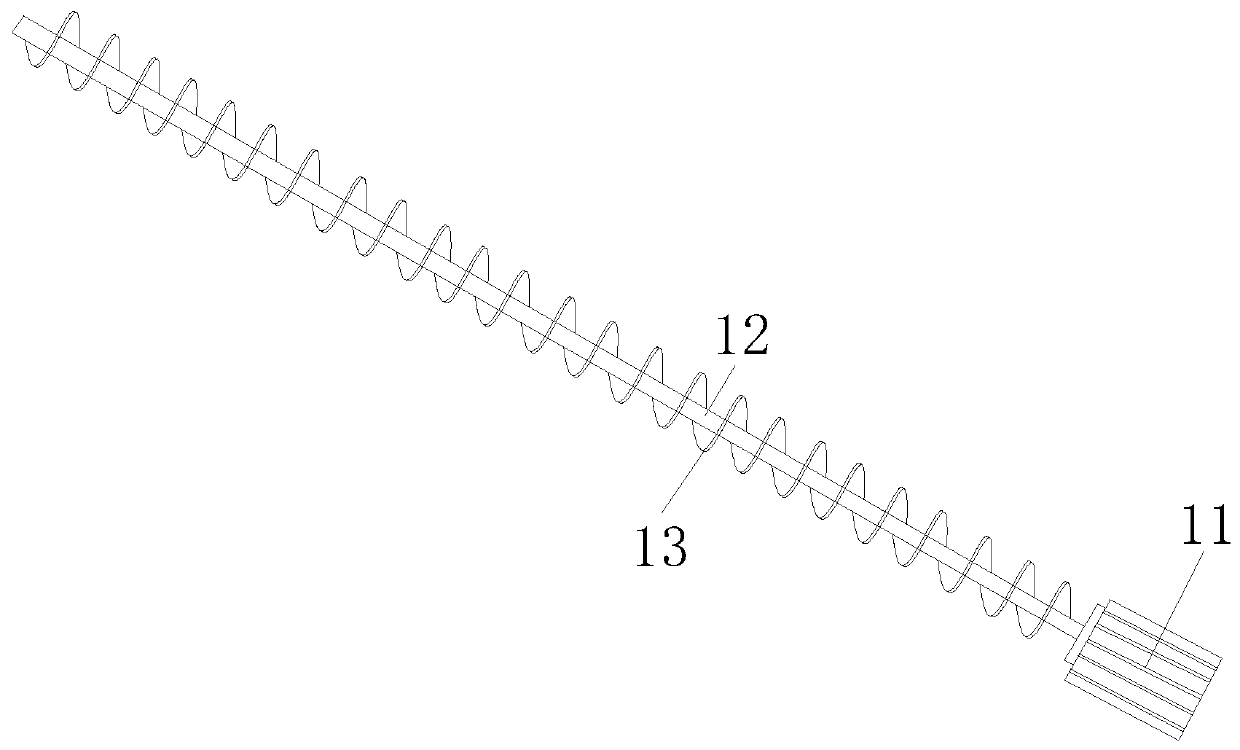

[0035] see figure 1 , figure 2 and image 3 , the present invention provides a construction aggregate crushing and conveying device through improvement, including a first supporting foot 1, a conveying cylinder 8, a crushing support plate 15 and a multi-stage crushing and screening device 14, the first supporting foot 1 and the crushing frame 2 Bottom bolt connection, the front end of crushing frame 2 is provided with control panel 3, the front end of control panel 3 is equipped with button 4, the rear end of crushing frame 2 is fixed with power wire 5, the top right end of crushing frame 2 is provided with feeding hopper 6, crushing frame 2 Tightly fix the top edge of the conveyor bucket 7 by electric welding, and the conveyor bucket 7 is connected to the right end of the top of the conveyor tube 8, the conveyor tube 8 is connected to the top of the discharge bucket 9 and the seam is welded and fixed, and the conveyor tube 8 is connected to the second support foot 10 The t...

Embodiment 2

[0042] The present invention provides a construction aggregate crushing and conveying device through improvement. The bottom of the electromagnet 1419 is provided with an insulating pad 14191, and the upper end of the electromagnet 1419 and the insulating pad 14191 is tightly fixed, and the right end of the electromagnet 1419 is provided with a fixing groove 14192. , and the fixed groove 14192 is one-eighth of a circular arc shape, the right end of the crushing plate 1427 is provided with a wear-resistant block 14271, and the wear-resistant block 14271 is fixed with the lower right end of the crushing plate 1427 as a whole, and the middle part of the second sliding cavity 1447 is provided with a sliding slot 14771, and the second sliding block 1445 is slidingly fitted along the inner side of the sliding slot 14771, the lower end of the flow guide partition 14411 is provided with a sliding slot 144111, and the crushing tooth plate 1449 is slidingly fitted inside the sliding slot ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com