Wavy basketball manufacturing process

A production process, basketball technology, applied to balls, inflatable hollow balls, sports accessories, etc., can solve the problems of high cost, easy to slip and fall off, poor effect, etc., and achieve the effect of beautiful radian and perfect wave shape.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The manufacturing process of wave basketball includes the following steps:

[0036] S1, preparation of liner 1: put rubber into the mold to make liner 1; the raw materials of rubber are: 50 parts of natural rubber, 10 parts of synthetic rubber, 5 parts of carbon fiber, 2 parts of crosslinking agent and 4 parts of filler;

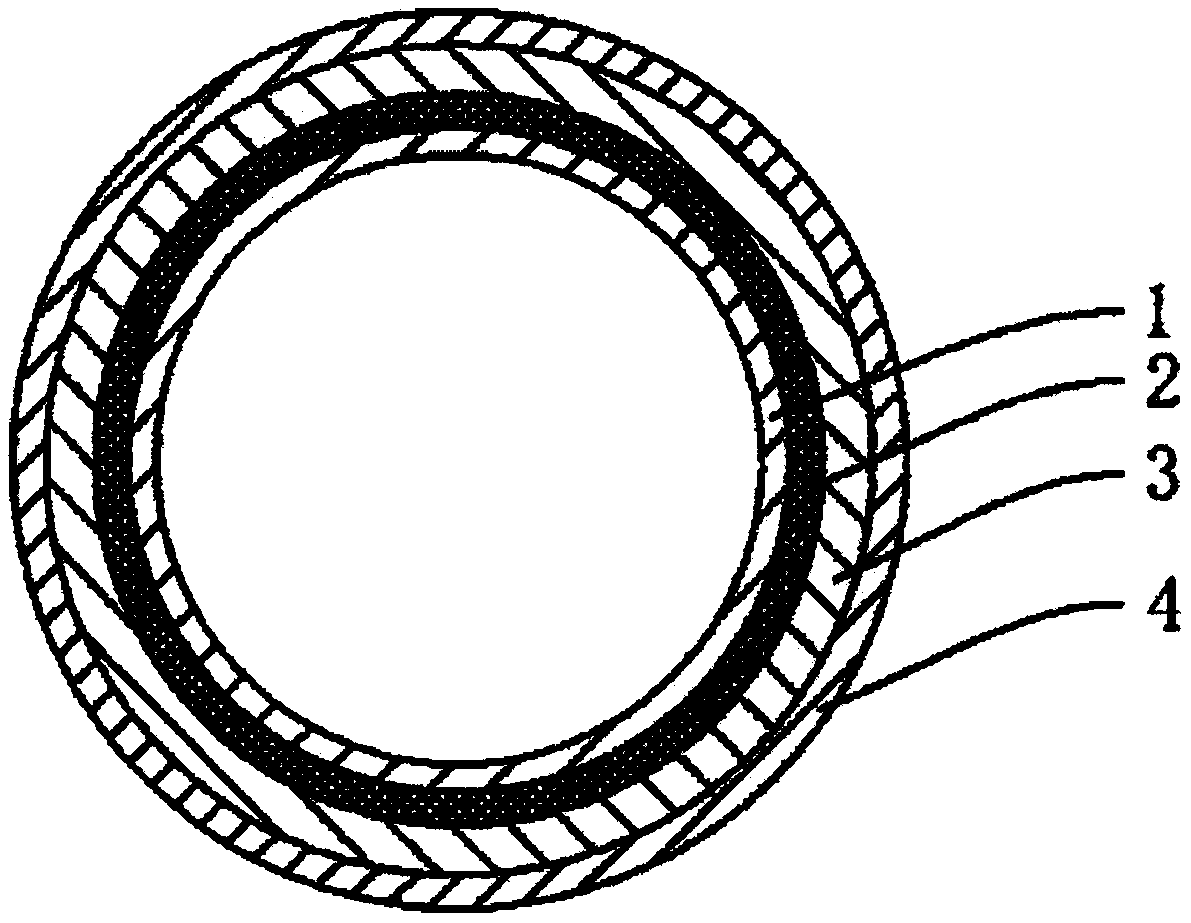

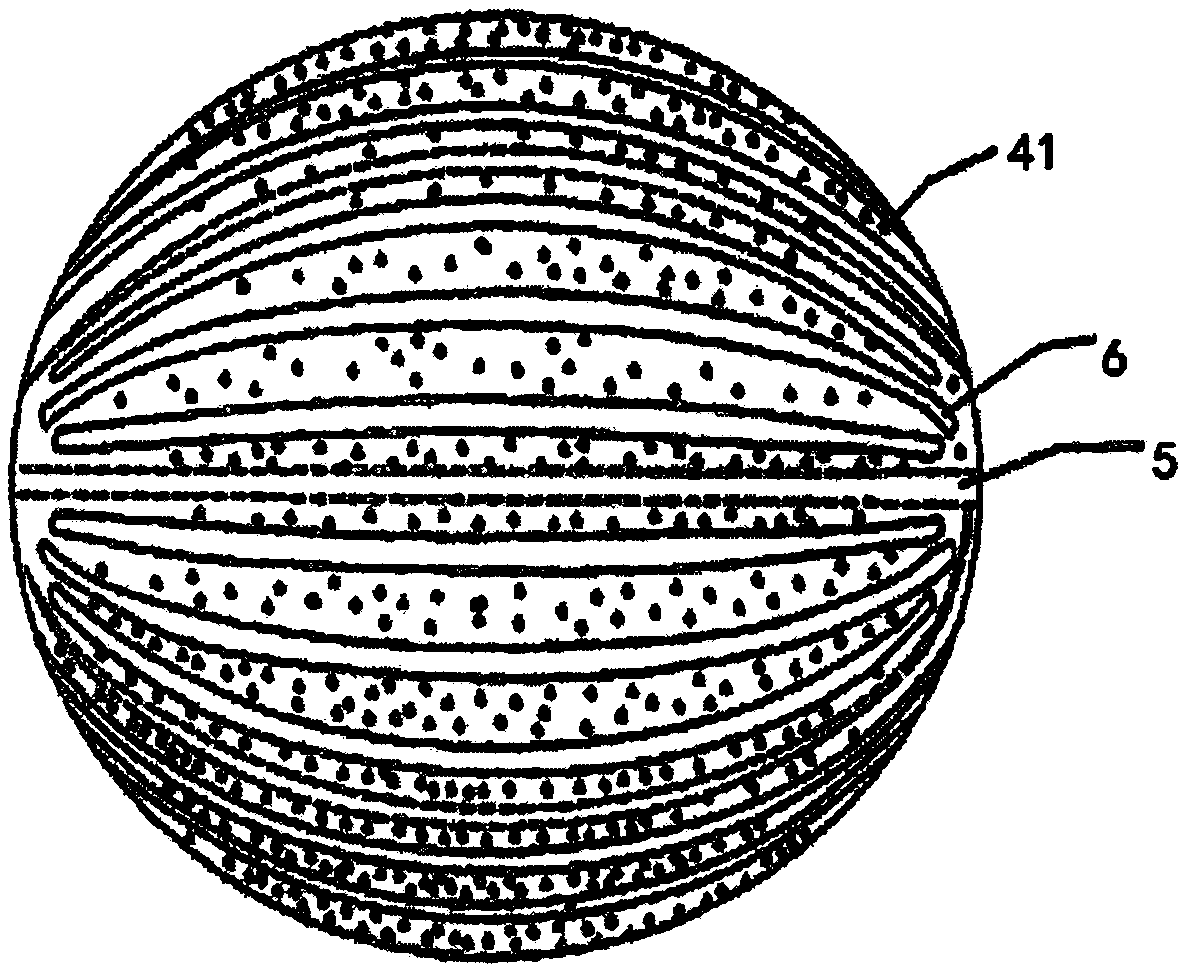

[0037] S2, preparation of yarn-wrapping layer 2 and middle tire layer 3: winding yarn on the surface of inner tank 1 to form yarn-wrapping layer 2, attaching middle tire skin to the outer surface of yarn-wrapping layer 2 to form middle tire layer 3, middle tire layer 3. Apply glue on the surface, dry and set the shape, and obtain the bladder blank; the raw materials of the middle tire skin and the skin are: 40 parts of natural rubber, 20 parts of synthetic rubber, 3 parts of zinc oxide, 0.5 part of stearic acid, and 2 parts of white corundum. 1 part, 20 parts of activated calcium carbonate, 1 part of white carbon black, 0.5 part of naphthenic oil, 1 p...

Embodiment 2

[0042] The manufacturing process of wave basketball includes the following steps:

[0043] S1, preparation of liner 1: put rubber into the mold to make liner 1; the raw materials of rubber are: 70 parts of natural rubber, 20 parts of synthetic rubber, 10 parts of carbon fiber, 5 parts of crosslinking agent and 5 parts of filler;

[0044] S2, preparation of yarn-wrapping layer 2 and middle tire layer 3: winding yarn on the surface of inner tank 1 to form yarn-wrapping layer 2, attaching middle tire skin to the outer surface of yarn-wrapping layer 2 to form middle tire layer 3, middle tire layer 3. Apply glue on the surface, dry and set the shape, and obtain the bladder blank; the raw materials of the middle tire skin and the skin are: 50 parts of natural rubber, 30 parts of synthetic rubber, 3.5 parts of zinc oxide, 5 parts of white corundum, and 0.7 parts of stearic acid. 30 parts, 30 parts of activated calcium carbonate, 5 parts of white carbon black, 1 part of naphthenic oil...

Embodiment 3

[0049] The manufacturing process of wave basketball includes the following steps:

[0050] S1, preparation of liner 1: put rubber into the mold to make liner 1; the raw materials of rubber are: 70 parts of natural rubber, 20 parts of synthetic rubber, 10 parts of carbon fiber, 5 parts of crosslinking agent and 5 parts of filler;

[0051] S2, preparation of yarn-wrapping layer 2 and middle tire layer 3: winding yarn on the surface of inner tank 1 to form yarn-wrapping layer 2, attaching middle tire skin to the outer surface of yarn-wrapping layer 2 to form middle tire layer 3, middle tire layer 3. Apply glue on the surface, dry and set the shape to get the bladder blank; the raw materials of the middle tire skin and the skin are: 50 parts of natural rubber, 30 parts of synthetic rubber, 3.5 parts of zinc oxide, 4 parts of white corundum, 0.7 parts of stearic acid 30 parts of activated calcium carbonate, 5 parts of white carbon black, 1 part of naphthenic oil, 2 parts of acceler...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com