A kind of pulping method of cigarette wick material and slurry, cigarette wick material and preparation method thereof

A cigarette core and pulping technology, which is applied in the field of tobacco products, can solve problems such as poor processing resistance and poor quality stability of tobacco products, and achieve the effects of simple and easy-to-operate preparation methods, improved refinement effect, and reduced equipment surface wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

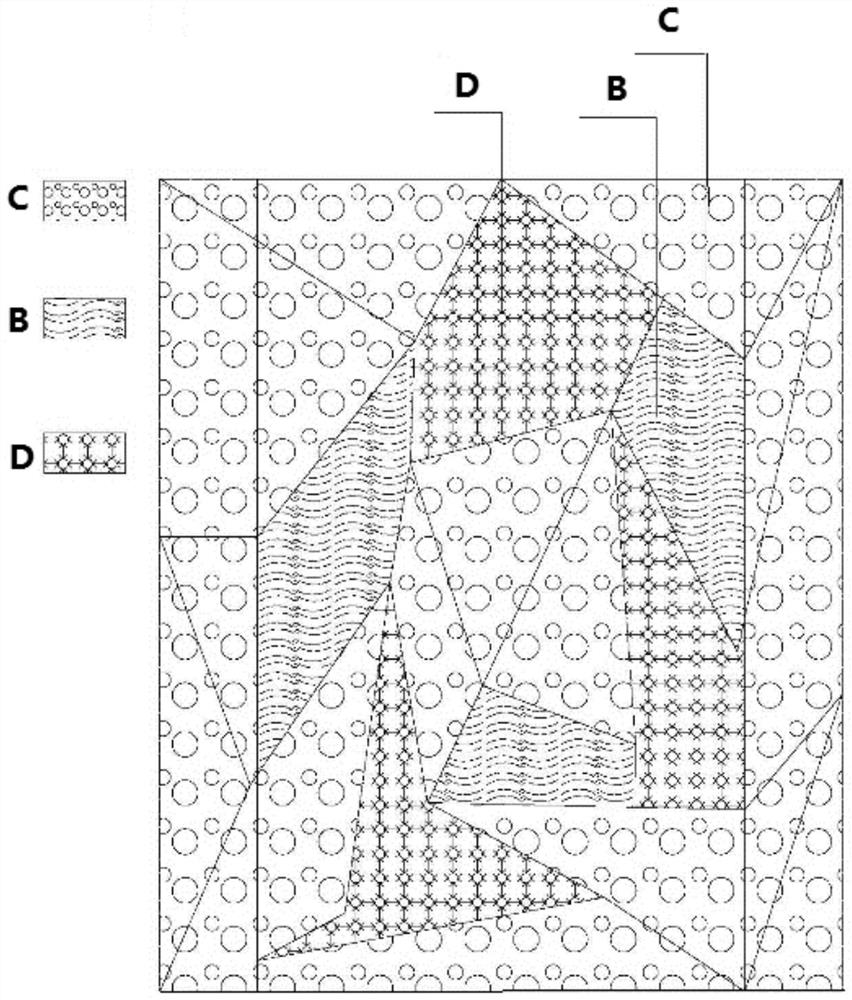

Image

Examples

preparation example Construction

[0072] In addition, the present invention also provides a method for preparing a cigarette wick material, which includes the following steps: drying the slurry prepared by the above-mentioned pulping method, followed by molding.

[0073] In some embodiments, the slurry is first coated on the surface of the carrier, then dried and shaped. Wherein, the carrier may be a metal carrier, and for reference, the metal carrier may be in the shape of a belt, that is, the metal carrier is a metal belt. The material of the metal carrier may include, for example, iron, stainless steel, aluminum or copper.

[0074] For reference, drying can be performed under the condition of 60-120°C for 10-30min, preferably under the condition of 90°C for 15min. Drying can be carried out by, but not limited to, drying. Under the drying conditions, not only can the moisture of the wick material be effectively removed, but also the appearance and smoking quality of the wick material can be improved. Form...

Embodiment 1

[0082] The present embodiment provides a cigarette core material, the preparation method of which includes:

[0083] A. Preparation of slurry: The raw materials of the wick material and water are sheared and stirred at a high speed under the condition of 2500 rpm for 10 minutes.

[0084] The raw materials include dry materials. The dry material includes the main material and the auxiliary material in a weight ratio of 2:8, and the weight ratio of water and dry material is 3:1. The main material is cigar inner wrapping leaves, and the auxiliary materials include adhesive, spice and smoking agent. The adhesive is carboxymethyl cellulose, the flavor is air-dried tobacco leaves, and the fuming agent is propylene glycol. The mesh number of the dry material is 200 meshes. The temperature of the water was 30°C.

[0085] The order of adding the materials is as follows: first, add carboxymethyl cellulose to the water with high-speed shearing and stirring at 2500 rpm until it is com...

Embodiment 2

[0088] The difference between this example and Example 1 is that the raw materials of the wick material and water are stirred at high speed for 8 minutes under the condition of 5000 rpm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com