Full-ceramic lithium ion battery diaphragm and preparation method thereof

A technology of lithium-ion batteries and ceramics, which is applied in the direction of secondary batteries, battery components, circuits, etc., can solve the problems of high temperature easy shrinkage, decomposition, and affecting the thermal stability of the diaphragm, so as to eliminate safety problems and eliminate internal short circuits in the battery , Promote the effect of lithium ion transport

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Diatomaceous earth, lithium hydroxide, lanthanum oxide, methyl cellulose, and distilled water are mixed uniformly in a mass ratio of 88:7:0.1:0.4:4.5, molded, dried at 80°C for 4 hours, and calcined in a muffle furnace to 500°C. Insulate for 6 hours, and the heating rate is 9°C / min; the obtained calcined sample is soaked in 0.05mol / L hydrochloric acid for 10 minutes, rinsed with distilled water until neutral, and dried at 100°C for 8 hours to obtain the all-ceramic lithium-ion battery separator.

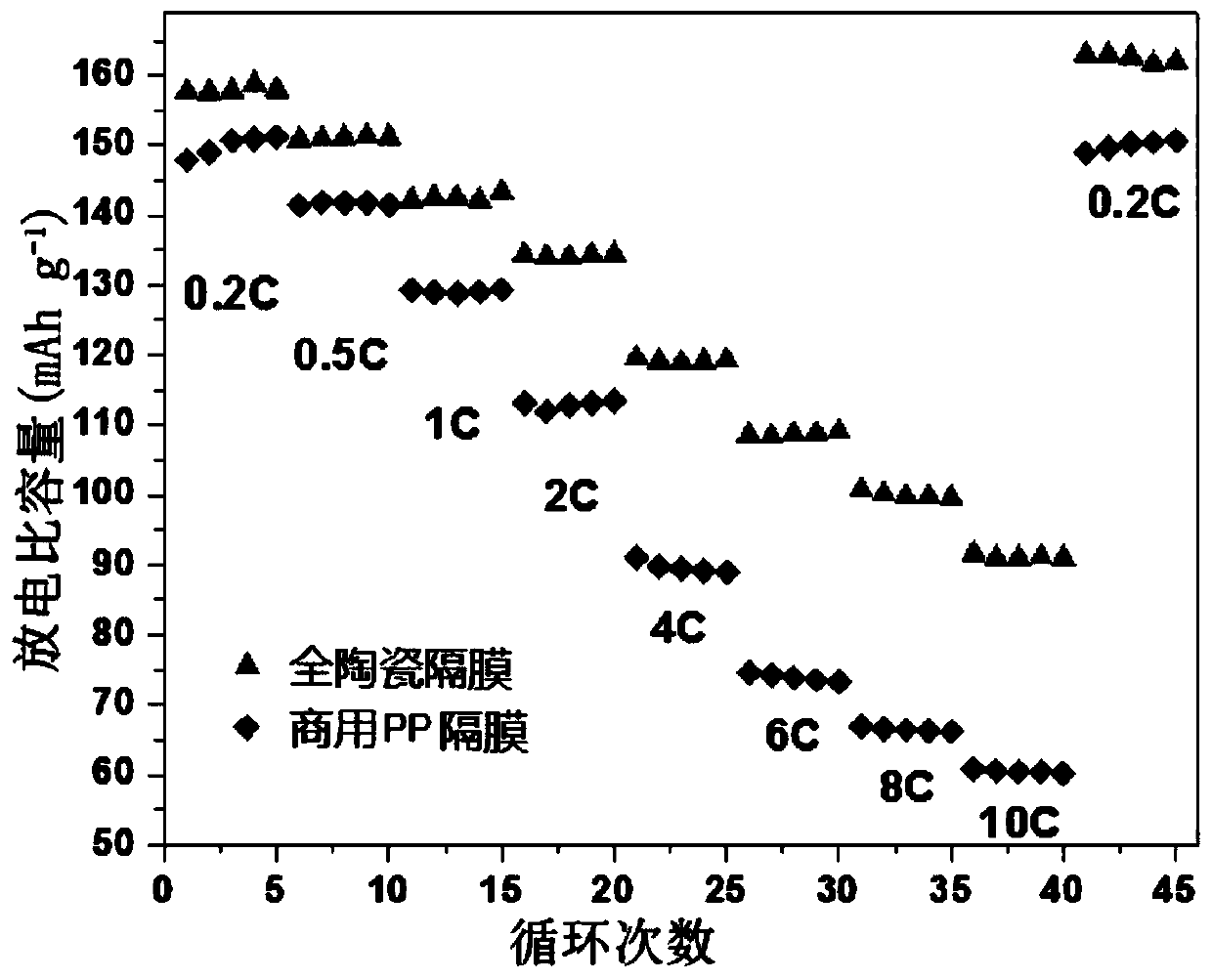

[0014] The all-ceramic lithium-ion battery separator has a porosity of 53.5%, a liquid absorption rate of 179%, and a discharge specific capacity of 92.9mAh g at a rate of 10C. -1 (lithium iron phosphate battery system).

Embodiment 2

[0016] Diatomaceous earth, lithium hydroxide, lanthanum oxide, hydroxypropyl methylcellulose, and distilled water are mixed uniformly in a mass ratio of 88:7:0.2:0.3:4.5, molded, dried at 80°C for 4 hours, and calcined in a muffle furnace to 520°C, keep warm for 5 hours, and the heating rate is 8°C / min; the obtained calcined sample is soaked in 0.05mol / L hydrochloric acid for 10 minutes, rinsed with distilled water until neutral, and dried at 100°C for 8 hours to obtain the all-ceramic lithium-ion battery separator .

[0017] The all-ceramic lithium-ion battery separator has a porosity of 51.4%, a liquid absorption rate of 168%, and a discharge specific capacity of 90.1mAh g at a rate of 10C. -1 (lithium iron phosphate battery system).

Embodiment 3

[0019] Diatomaceous earth, lithium hydroxide, cerium oxide, hydroxyethyl cellulose, and distilled water are mixed uniformly in a mass ratio of 88:7:0.3:0.2:4.5, molded, dried at 80°C for 4 hours, and calcined in a muffle furnace to 540°C , kept warm for 4 hours, and the heating rate was 7°C / min; the obtained calcined sample was soaked in 0.05mol / L hydrochloric acid for 10 minutes, rinsed with distilled water until neutral, and dried at 100°C for 8 hours to obtain the all-ceramic lithium-ion battery separator.

[0020] The all-ceramic lithium-ion battery separator has a porosity of 54.6%, a liquid absorption rate of 189.0%, and a discharge specific capacity of 96.6mAh g at a rate of 10C. -1 (lithium iron phosphate battery system).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal stability | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com