Lithium ion battery diaphragm and preparation method thereof

A lithium-ion battery and diaphragm technology, applied in the field of lithium-ion battery diaphragm and its preparation, can solve the problems of easy aggregation of ceramic particles, achieve the effect of strengthening hydrophobicity, improving liquid absorption and retention capacity, and uniform pore distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

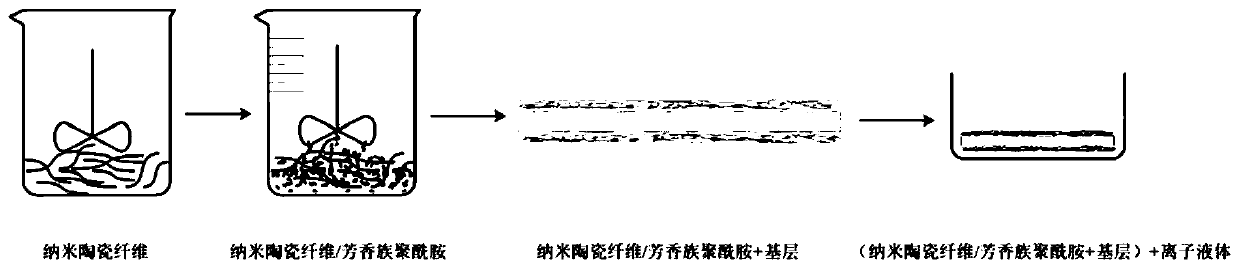

[0045] The preparation method of lithium-ion battery diaphragm of the present invention comprises the following steps:

[0046] 1) Add the nano-ceramic fiber and dispersant to the solvent and stir evenly, then ultrasonically disperse to obtain the nano-ceramic fiber mixture; the nano-ceramic fiber is at least aluminum oxide, zirconium oxide, silicon oxide, titanium oxide, silicon nitride One; the dispersant is at least one of polyacrylamide, hydroxypropyl methylcellulose, and triethyl phosphate, and the mass percentage of the dispersant is 3% to 10%; the solvent is N - At least one of methylpyrrolidone, chloroform, dimethylacetamide, and tetrahydrofuran; the stirring time is 10-30min, and the stirring speed is 200-600r / min; the ultrasonic dispersion, dispersion The time is 10-30min, and the dispersion frequency is 10-110KHz;

[0047] 2) Add a co-solvent to the above mixed solution, in a stirring state, then add raw material A to dissolve; the co-solvent is LiCl, CaCl 2 , Li ...

Embodiment 1

[0058] 1) Add silicon oxide nanofibers and polyacrylamide into chloroform and stir for 10 minutes at a stirring speed of 500r / min, then disperse in ultrasonic waves for 10 minutes at a dispersion frequency of 60KHz; obtain a mixed solution of silicon oxide nanofibers; In the mixed solution, the mass percentage of the nano-ceramic fiber is 10%; the mass percentage of the dispersant is 3%;

[0059] 2) Add LiCl to the above mixed solution, and keep stirring at a stirring speed of 600r / min, then add p-phenylenediamine and stir until completely dissolved; the mass of LiCl is 5% of the mass of the nano-ceramic fiber mixed solution;

[0060] 3) Lower the temperature to 5°C, increase the stirring speed to 900r / min, add terephthaloyl chloride, and react for 5 minutes to obtain a mixed solution of nano-ceramic fibers and in-situ polymerized aromatic polyamide, that is, before coating Mixed slurry; in the mixed slurry before coating, the mass percentage of nano-ceramic fiber is 5%, and t...

Embodiment 2

[0067] 1) Add silicon oxide nanofibers and polyacrylamide into chloroform and stir for 10 minutes at a stirring speed of 500r / min, then disperse in ultrasonic waves for 10 minutes at a dispersion frequency of 60KHz; obtain a mixed solution of silicon oxide nanofibers; In the mixed solution, the mass percentage of the nano-ceramic fiber is 8%; the mass percentage of the dispersant is 3%;

[0068] 2) Add LiCl to the above mixed solution, and keep stirring at a stirring speed of 600r / min, then add p-phenylenediamine and stir until completely dissolved; the mass of LiCl is 3% of the mass of the nano-ceramic fiber mixed solution;

[0069] 3) Lower the temperature to 5°C, increase the stirring speed to 900r / min, add terephthaloyl chloride, and react for 5 minutes to obtain a mixed solution of nano-ceramic fibers and in-situ polymerized aromatic polyamide, that is, before coating Mixed slurry; in the mixed slurry before coating, the mass percentage of nano-ceramic fiber is 3%, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com