Broadband temperature tuning filter with air gap etalon structure

A technology for tuning filters and etalons, applied in instruments, optical components, optics, etc., can solve problems such as difficult bonding, and achieve the effect of satisfying parallelism and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

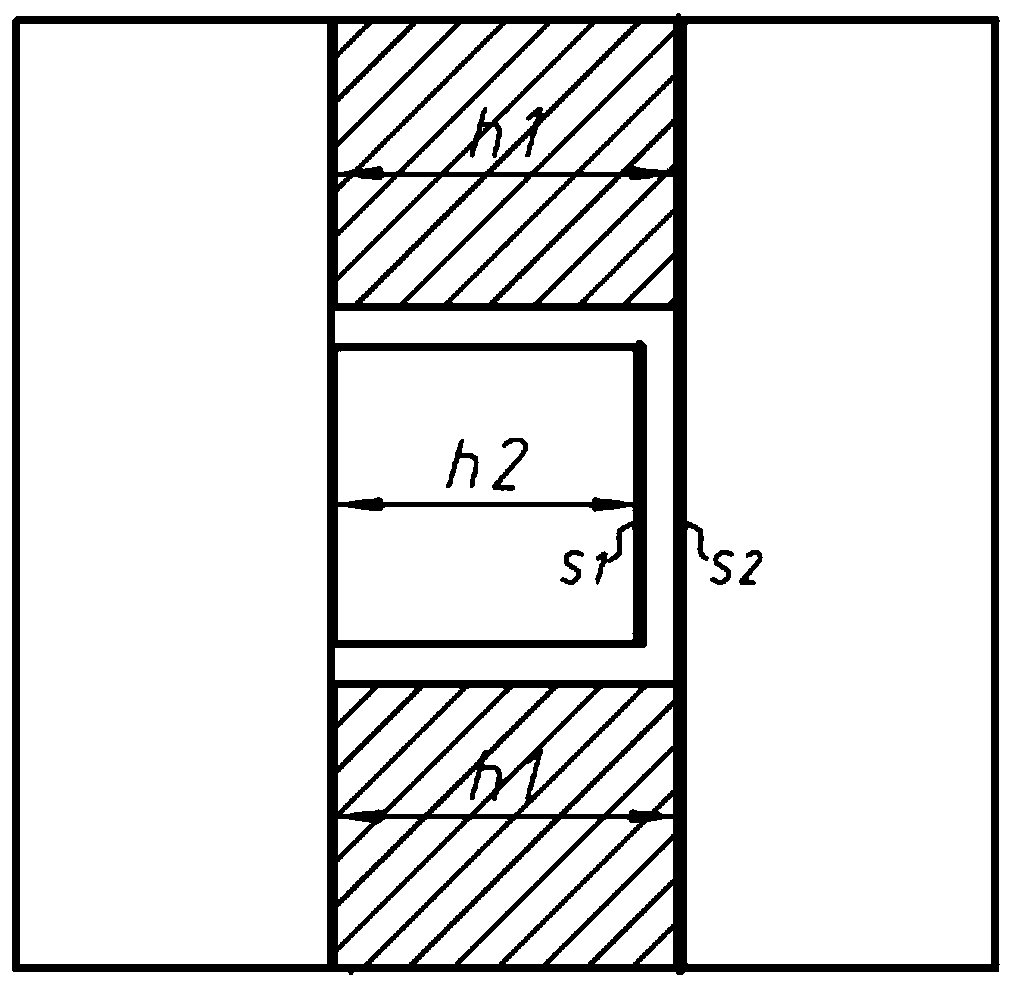

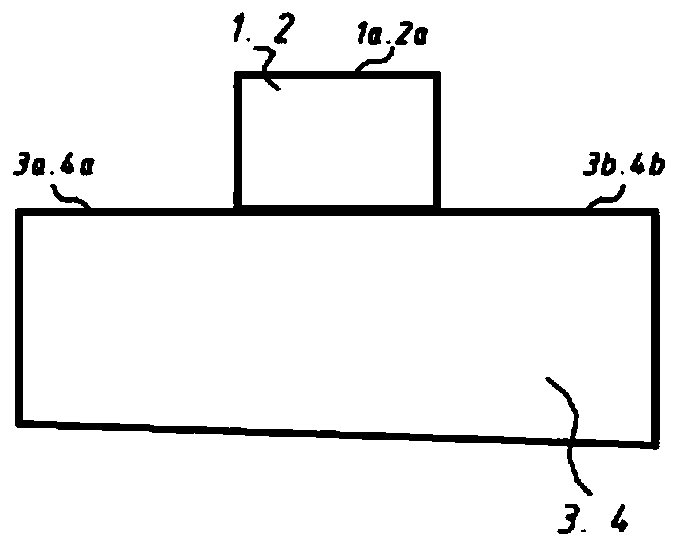

[0027] see Figures 3 to 5 , a wide-band temperature-tuned filter with an air-gap etalon structure, including an air-gap etalon, the air-gap etalon is composed of H-K9 and a quartz crystal, the quartz crystal is a hexagonal crystal structure, isotropic Anisotropic uniaxial crystals have anisotropic thermal expansion, and the thermal expansion coefficient of the quartz crystal: ||C: 7.97x10-6 / °C; ⊥C: 13.3x10-6 / °C@0°-80°°C, optional The surface of the quartz crystal parallel to the c-axis is the bonding surface, and the expansion and contraction direction is perpendicular to the c-axis when the temperature changes. The H-K9L is an optical glass, an isotropic material, and the thermal expansion coefficient is 7.6E-6 / °C.

[0028] Among them, the design parameters include:

[0029] The a-axis thermal expansion coefficient of quartz crystal is 13.3E-6 / ℃, 1.88mm;

[0030] H-K9L thermal expansion coefficient is 7.6E-6 / ℃, 1.8548mm;

[0031] 25℃, air gap 25.2um, FSR47.67nm, R90.0%, F...

Embodiment 2

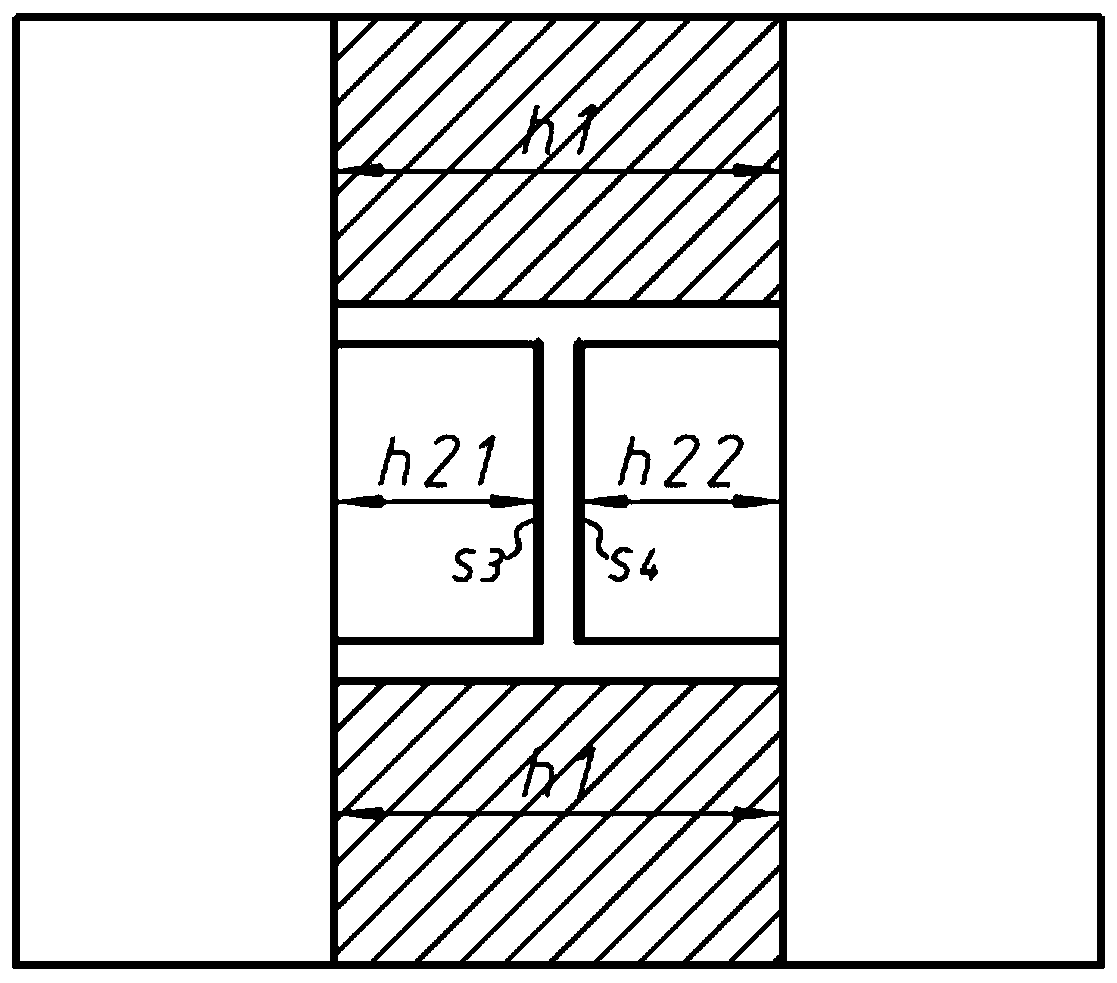

[0041] see Figure 6-8 , a broadband temperature-tuned filter with an air-gap etalon structure, including H-K9 and Brofloat33;

[0042] Among them, the design parameters include:

[0043] H-K9L thermal expansion coefficient is 7.6E-6 / ℃, 2.5mm;

[0044] Brofloat33 thermal expansion coefficient is 3.25E-6 / ℃, 2.4748mm;

[0045] 25℃, air gap 25.2um, FSR47.67nm, R90.0%, FWHM201.16G;

[0046] The variation of cavity thickness per degree Celsius = 7.6E-6x2.5-3.25E-6x2.4748mm = 1.1E-5mm = 11nm;

[0047] 95°C, air gap 25.97um, FSR46.25nm, FWHM195.19G.

[0048] Design steps include:

[0049] Step 1. Throw Brofloat33 parallel flat sheets 11 and 12 with surface shape <1 / 20@633nm, parallelism <1 second, width 1.8mm, thickness 1.237mm, and the total thickness of the two pieces is 2.475mm;

[0050] Polished H-K9 wedge angle piece 13, 14 surface shape <1 / 10@633nm, wedge angle 30+ / -1 minute, width 3mm, thickness 0.71mm;

[0051] Polished H-K9 parallel flat plate 15, 16 surface shape 1 / 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com