Height-adjustable cutting system with internal power

A technology of internal power and transmission system, applied in cutting machinery, driving device, slitting machinery, etc., can solve the problems of complex geological conditions and low mining height, and achieves guaranteed mining height range, increased machine surface height, and compact structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

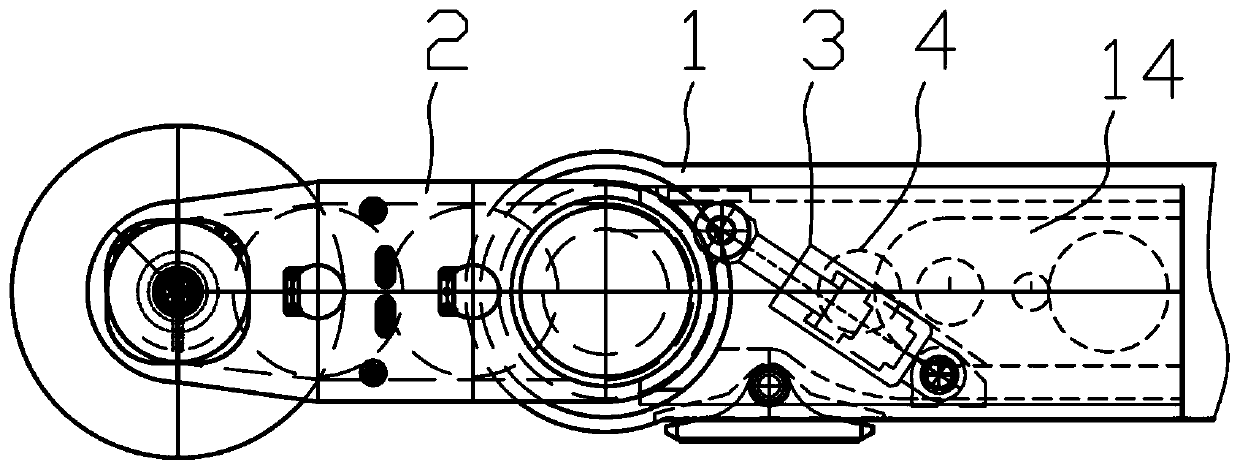

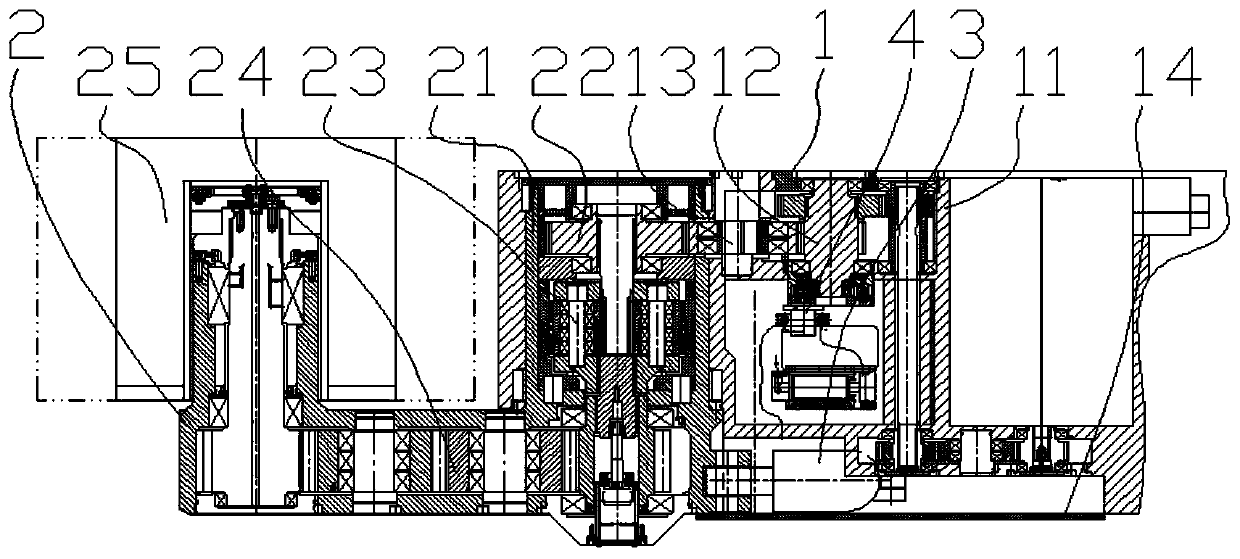

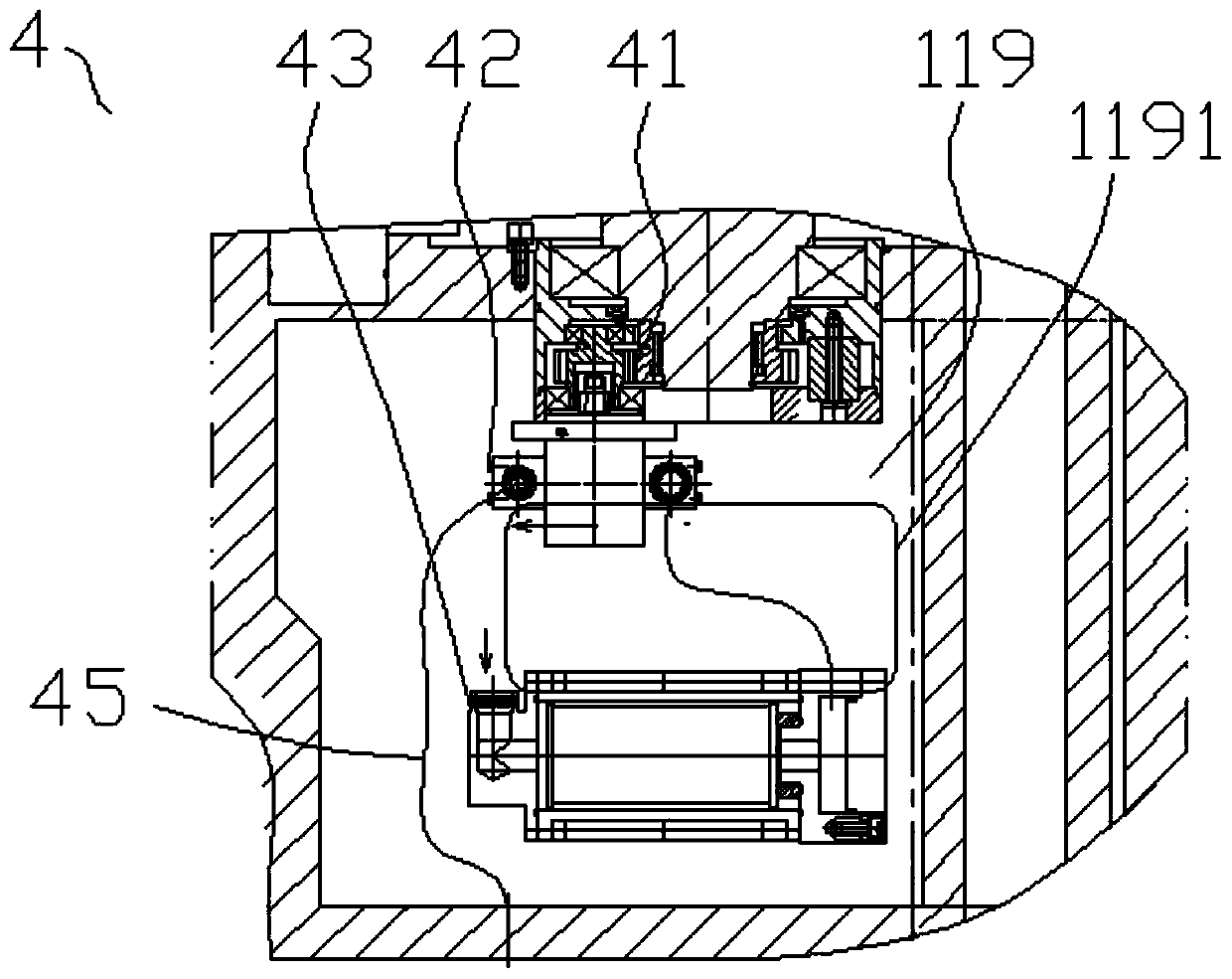

[0044] The invention discloses a height-adjustable cutting system with internal power, such as Figure 1-16 As shown, it includes a non-oscillating transmission part 1, a motorless rocker arm 2, a cutting motor, a hydraulic system 4 and an oil cylinder 3. The non-oscillating transmission part includes a static housing 11 and a front-stage transmission system arranged in the static housing. The motorless rocker arm is equivalent to a swing transmission part, including a rocker arm housing 21 and a rear stage transmission system arranged in the rocker arm housing. A motor installation cavity and a rocker arm installation cavity 114 are arranged in the static housing, the cutting motor is fixedly installed in the motor installation cavity, and the root of the cylindrical structure of the rocker arm housing is rotatably supported on the The rocker arm is installed in the cavity so that the rocker arm housing can swing with a fixed axis relative to the static housing, wherein the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com