Environment-friendly energy-saving fabricated steel structure factory building structure

An environmentally friendly, energy-saving, assembly-type technology, applied in thermal insulation, building components, heating methods, etc., can solve problems such as poor heat dissipation, achieve the effects of reducing cross-sectional area, saving steel, and reducing the maximum bending moment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

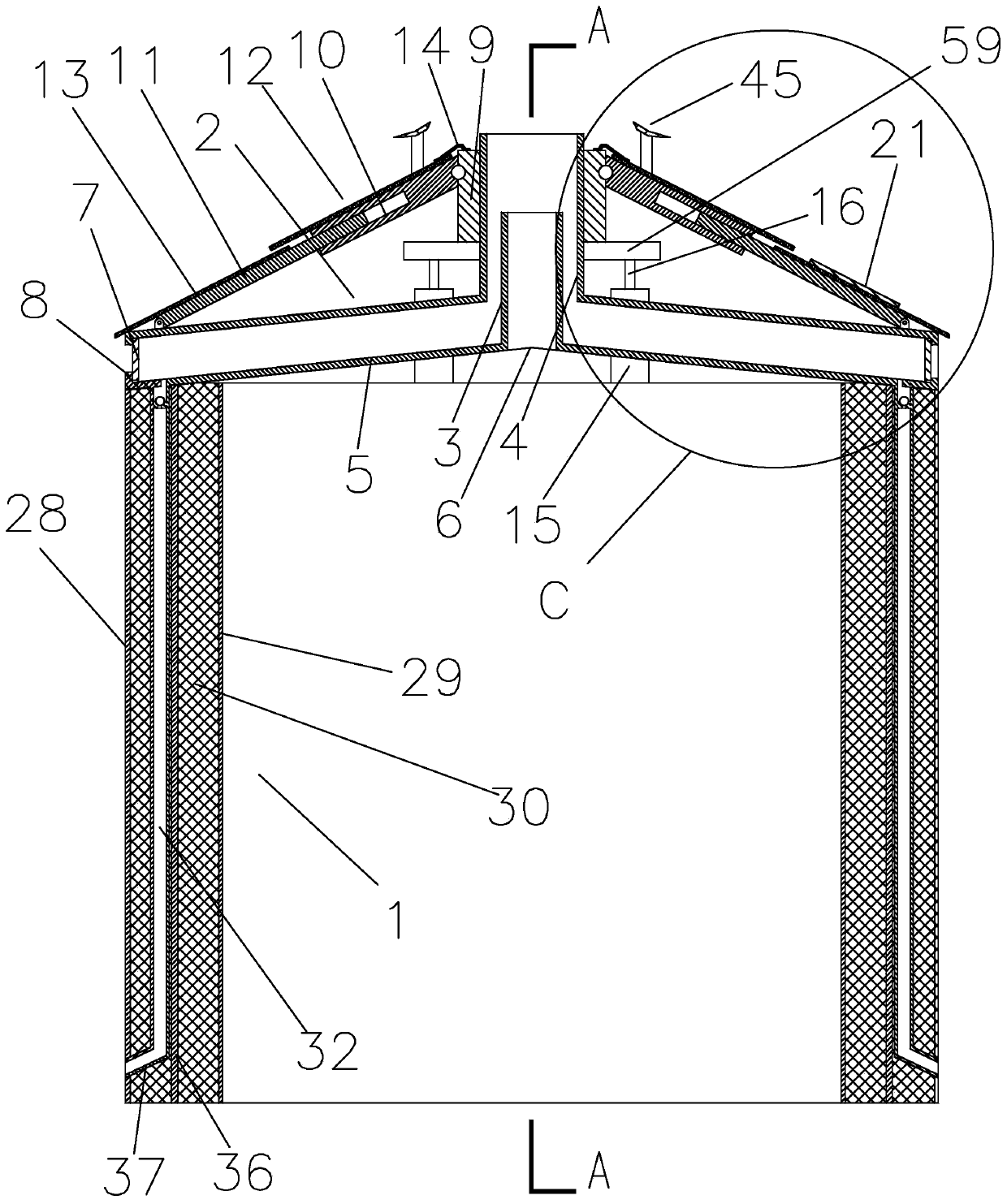

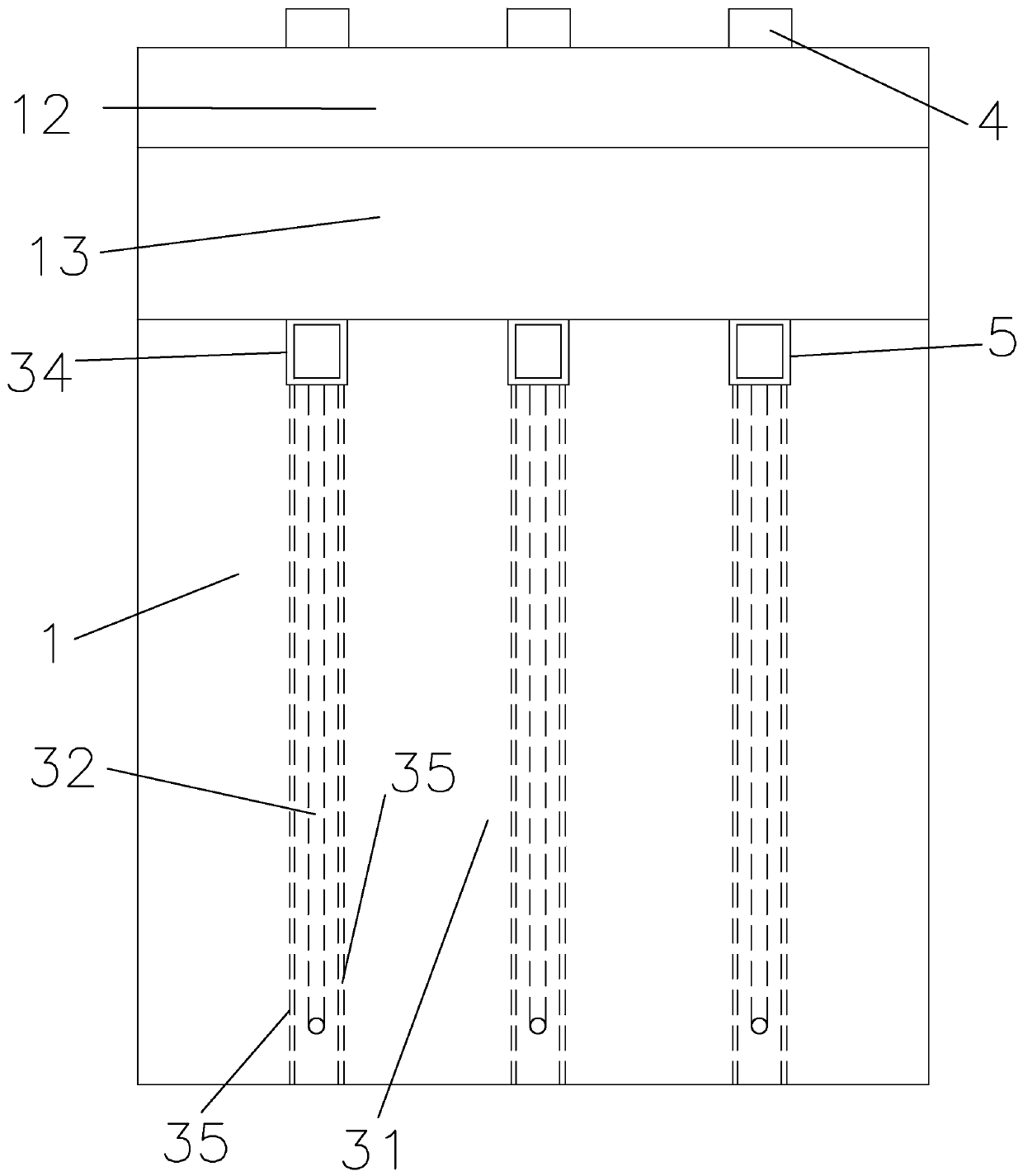

[0035] see Figure 1 to Figure 10 , an environment-friendly and energy-saving prefabricated steel structure workshop structure, comprising a wall 1, several air-exhausting steel beams 2 erected on opposite sides of the wall 1, and a roof located above the air-extracting steel beams 2;

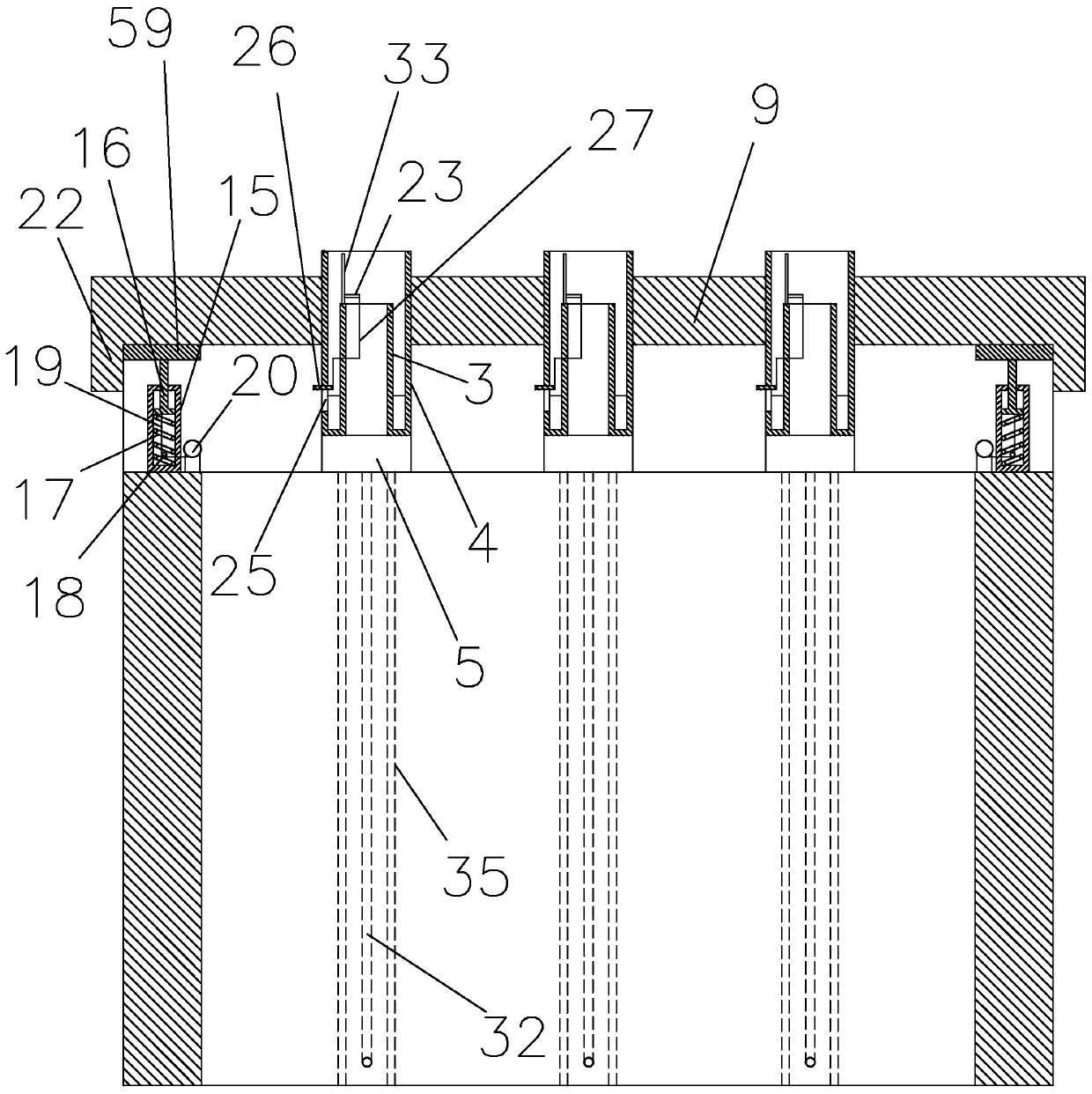

[0036] The air extraction steel beam 2 includes a ventilation pipe 5 whose end is erected on the wall 1, an outer cylinder 4 whose lower end communicates with the ventilation pipe 5, and an inner cylinder 3 located in the outer cylinder 4. The lower end of the inner cylinder 3 is connected to the ventilation pipe 5. The lower side wall of the pipe 5 is fixed, and the lower side wall of the ventilation pipe 5 is provided with a ventilation hole 6 at the corresponding position of the inner cylinder 3; The end of the ventilation pipe 5 is provided with a one-way valve facing the inside of the ventilation pipe 5. The one-way valve includes a valve plate 7 whose upper end is rotatably connected to t...

Embodiment 1

[0052] The number of the rainproof cover in Example 1 is one and the area is relatively large. When the rainproof cover is opened, one side of the airflow coming out of the ventilation pipe is blocked by the rainproof cover, so that the airflow above the inner cylinder can only be Being guided by the airflow on the other three sides, the diversion effect is reduced.

[0053] see Figure 11 to Figure 12 Therefore, an improved solution is proposed, which differs from Example 1 in that the cross-section of the inner cylinder is rectangular, the number of the rainproof covers is four, and the rainproof covers are respectively rotatably connected to the upper end of the inner cylinder On the four sides of the inner cylinder, the control rod is fixedly connected to the side of the rainproof cover facing the inner side of the inner cylinder. The inner cylinder is provided with an inner cylinder chute 51, and the inner cylinder is sleeved with a sliding groove for sealing the inner cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com