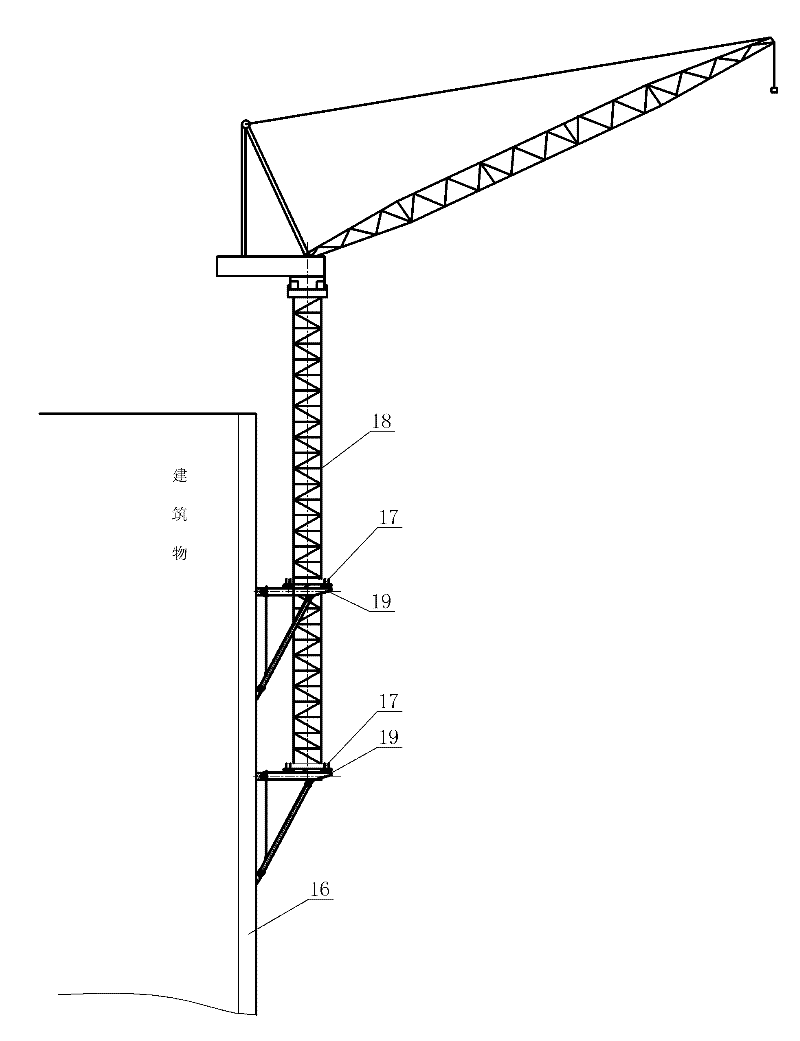

Suspended-rising support system of tower crane

A tower crane and suspension-climbing technology, which is applied in cranes and other directions, can solve the problems of increasing the use cost, excessive horizontal force, and increasing the cost of the structure, and achieves good adaptability, reduces horizontal loads, and saves materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

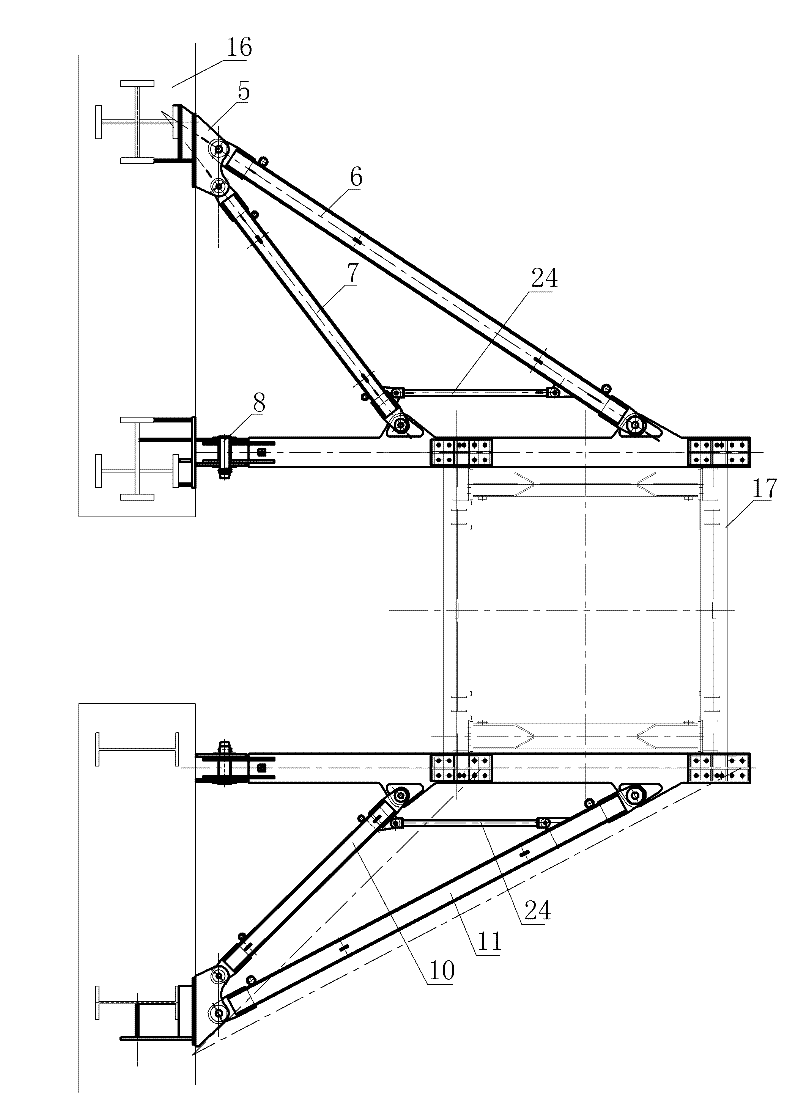

[0031] Example: such as figure 1 , figure 2 As shown, the present invention includes three sets of identical supporting structures 19, and two sets of adjacent supporting structures 19 are arranged up and down to support the tower body during normal operation. The support structure 19 includes a support frame 17, a main beam 2, two diagonal braces 3 supporting the main beam 2 at the lower part of the main beam, and first, second, third and fourth support bars supporting the main beam 2 in the horizontal direction. 6, 7, 10, 11; one end of the main beam 2 is connected to the embedded part in the wall 16 through the first ear plate 1, wherein the first ear plate 1 is connected to the main beam 2 through the first pin shaft 8, and the diagonal brace One end of the rod 3 is connected to the embedded part in the wall 16 through the second ear plate 4, and the first, second, third and fourth struts 6, 7, 10, 11 are respectively connected to the wall body through the third ear plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com