Long-acting slow-release black anti-freezing modifier for asphalt pavement and preparation method thereof

An anti-icing and modifier technology, applied in the field of long-acting slow-release black anti-icing modifier for asphalt pavement, to achieve excellent durability, good stress resistance, and excellent slow-release effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

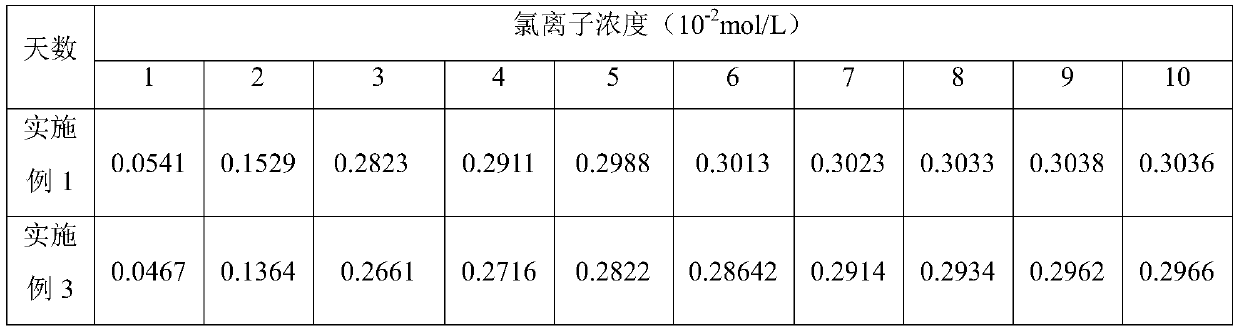

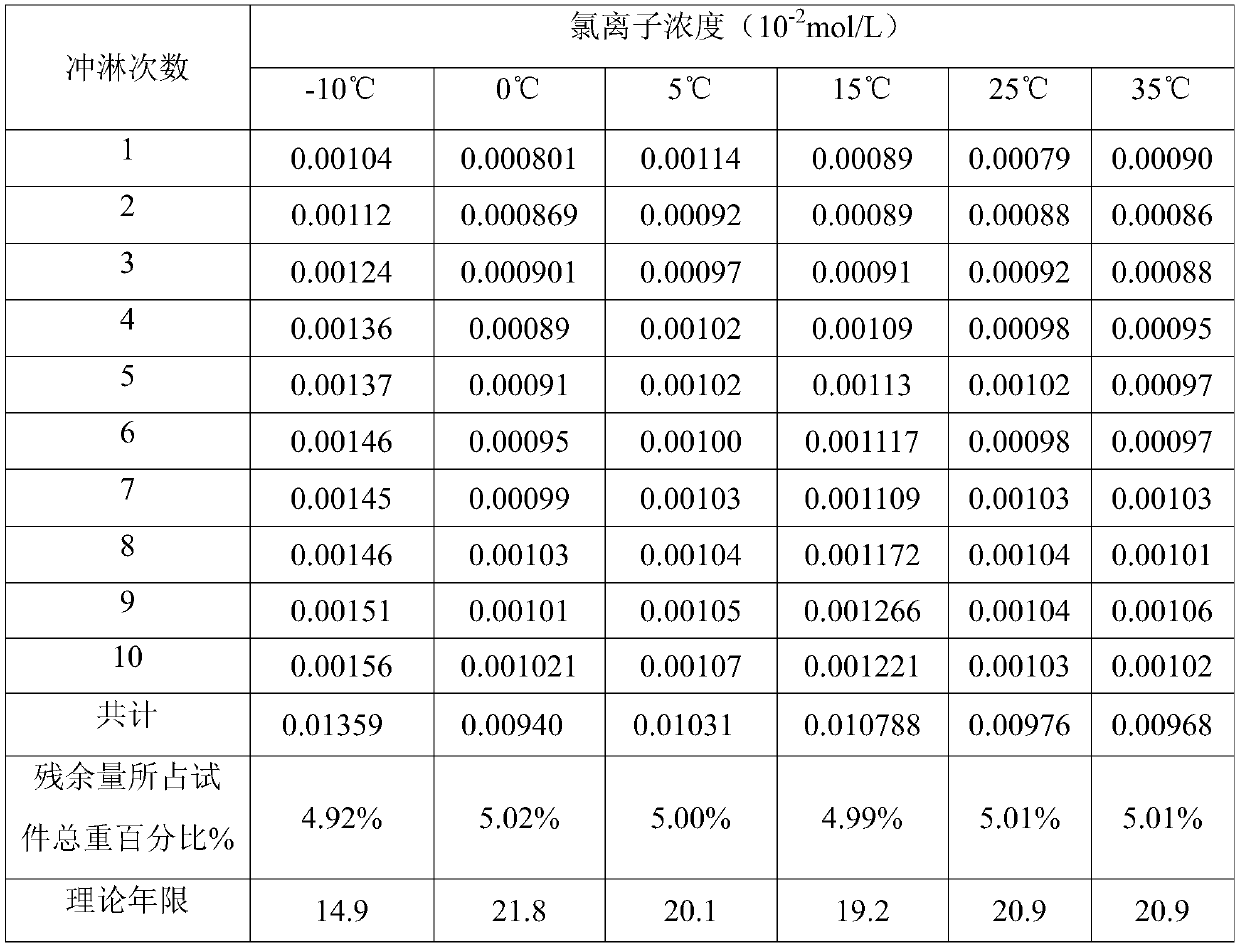

Embodiment 1

[0102] Calcium chloride, magnesium chloride and sodium chloride (all industrial grade, 2:2:6) and carbon black are added to tetrahydrofuran at a ratio of 1:15 (the addition amount is 10 times that of the solid mixed material), and Stir at 300r / min for 30min. Subsequently, tetrahydrofuran is removed at room temperature to obtain salt storage particles.

[0103] At room temperature, fully stir and dissolve asphalt, SBS and SBR (1:50:25) in tetrahydrofuran, add the above-mentioned salt storage particles to it, stir at 100r / min for 30min, fully stir and coat. Subsequently, it is dried at 60°C, and granulated and sieved to make the particle size of the black anti-icing ice modifier less than 5 mm. By weighing calculation, the coating material is about 100 parts by mass relative to 100 parts by mass of salt storage particles.

[0104] The dried material is cooled to room temperature, and then measured and packaged to obtain the black anti-coagulation ice modifier.

Embodiment 2

[0106] Potassium acetate and potassium formate (4:6) and carbon black were added to tetrahydrofuran (the addition amount was 10 times that of the solid mixed material) at a ratio of 1:15, and stirred at 300 r / min for 30 min. Subsequently, tetrahydrofuran is removed at room temperature to obtain salt storage particles.

[0107] At room temperature, fully stir and dissolve asphalt, SIS and SBS in tetrahydrofuran (1:50:25), add the above-mentioned salt storage particles to it, stir at 100r / min for 30min, and fully stir and coat. Subsequently, it is dried at 60°C, and granulated and sieved to make the particle size of the black anti-icing ice modifier less than 5 mm. According to weighing calculation, relative to 100 parts by mass of salt storage particles, the coating material is about 120 parts by mass.

[0108] The dried material is cooled to room temperature, and then measured and packaged to obtain the black anti-coagulation ice modifier.

Embodiment 3

[0110] In addition to mixing calcium chloride, magnesium chloride and sodium chloride with carbon black in tetrahydrofuran, further adding pitch (pitch: carbon black = 1:1) and stirring at 1500r / min for 15min; and coating time from 30min Except for 3 minutes, a black anti-coagulation ice modifier was obtained in the same manner as in Example 1. According to weighing calculation, the coating material is about 67 parts by mass relative to 100 parts by mass of salt storage particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com