Sunken gas station of dual-fuel container transport ship

A technology for filling stations and transport ships is applied in the field of submerged filling stations for dual-fuel container transport ships to achieve the effects of reducing filling risks, improving height differences, and shortening preparation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

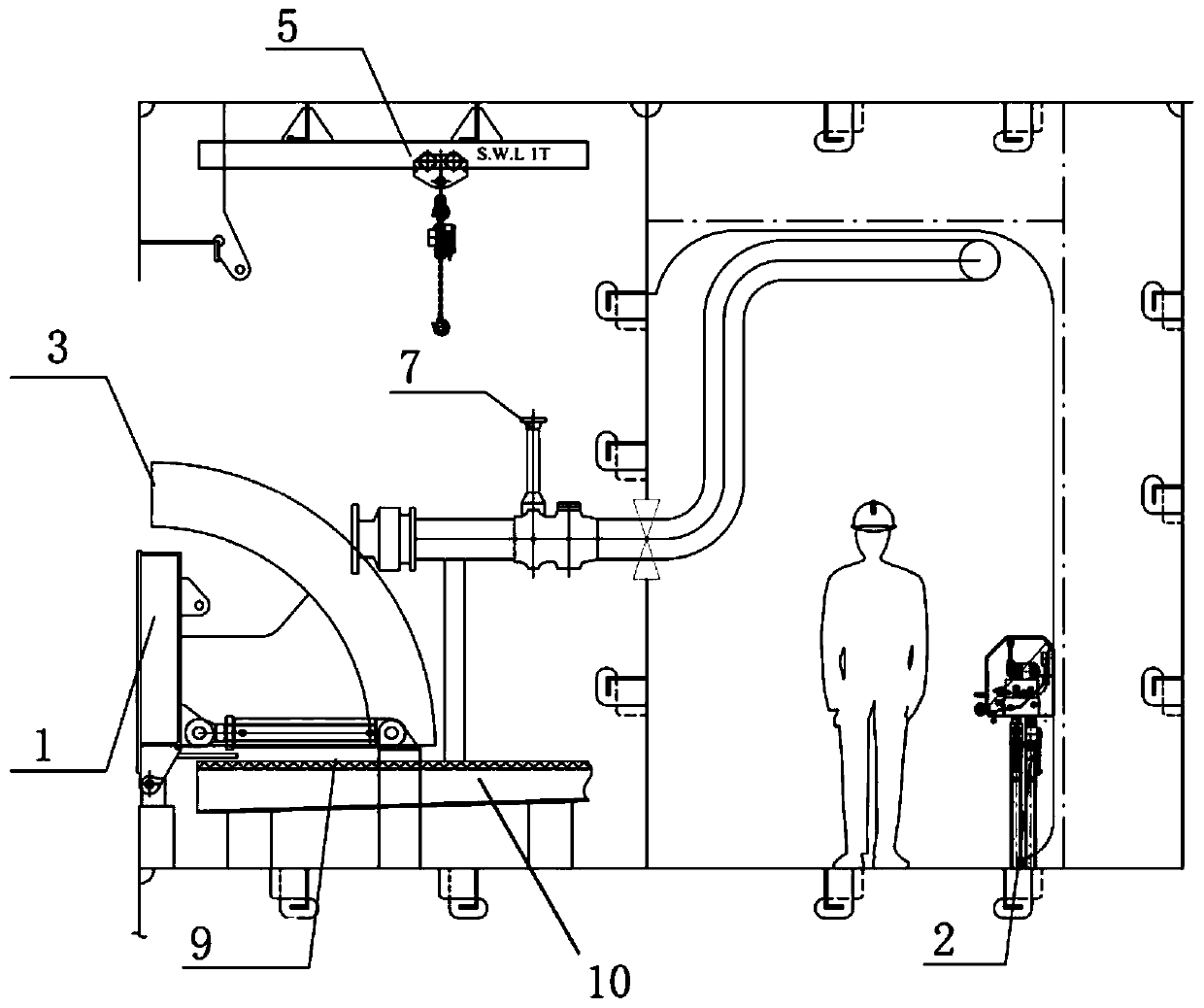

[0026] Such as Figure 1-5 As shown, the layout of a sinking gas filling station for a dual-fuel container ship can greatly improve the difference in freeboard height between the container ship and the bunkering ship, and the filling pipe of the bunkering ship can reach the gas filling station more safely and efficiently At the same time, the integrated design of the gas station door and the gas pipe saddle is adopted, and the gas filling hose adopts a quick connector, which can effectively shorten the filling time and reduce the risk during the filling process.

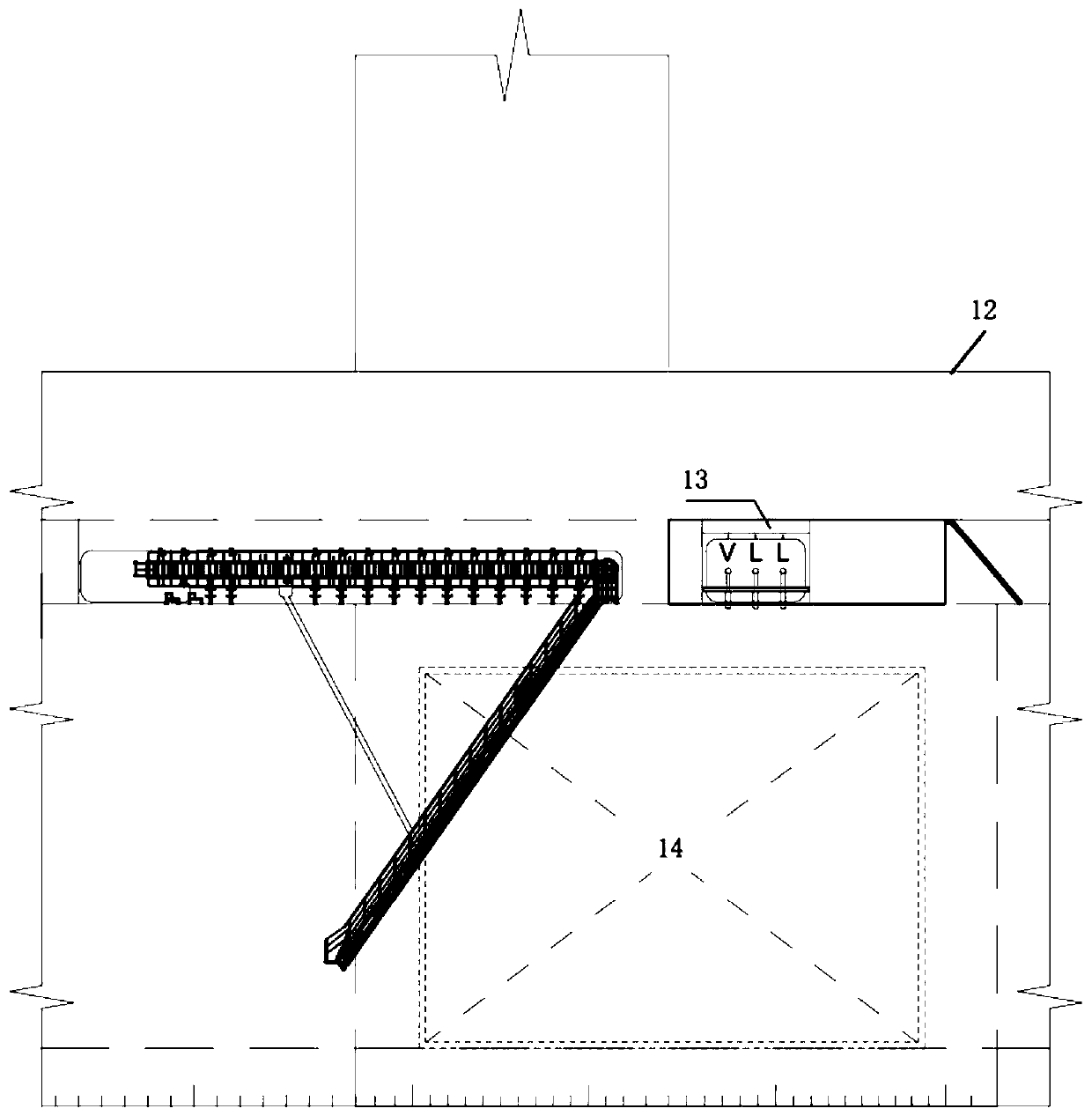

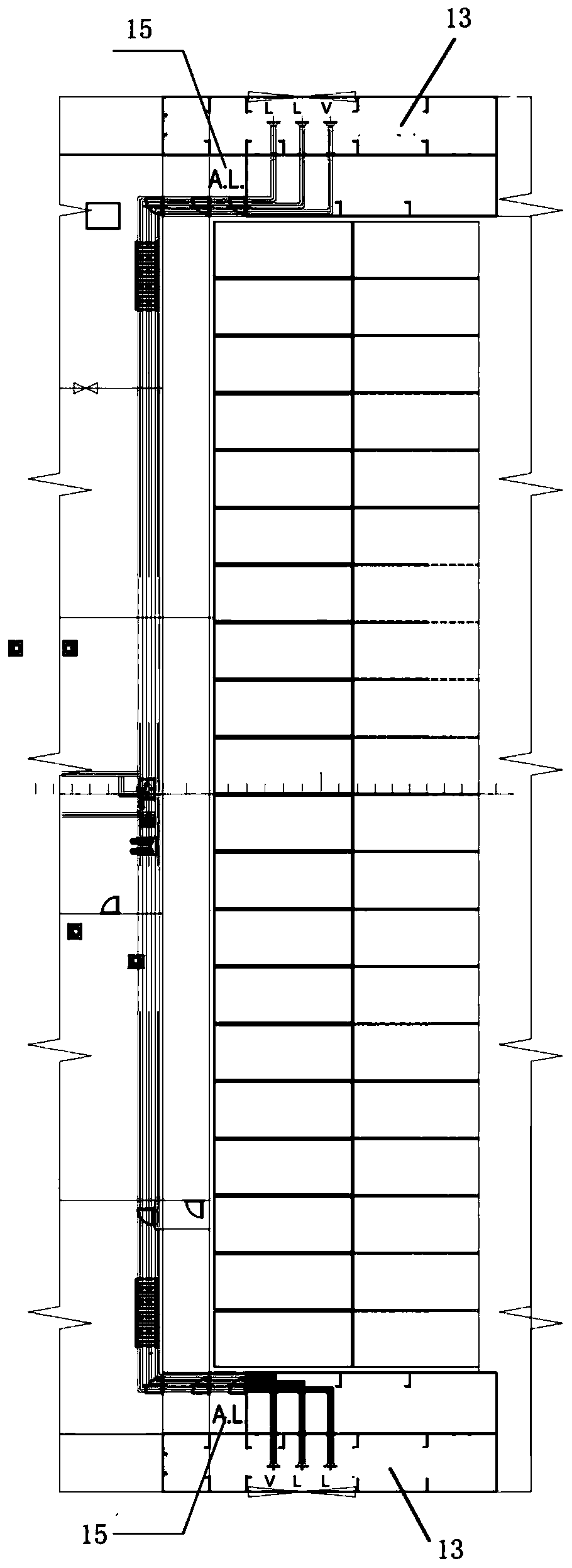

[0027] refer to figure 1 , is a side view of a sinking gas filling station for a container carrier using dual fuels. The gas filling station 13 is located below the main deck 12 and is close to the gas fuel tank 14.

[0028] refer to figure 2 , is a top view of a sinking gas filling station for a container carrier using dual fuels. The gas filling station 13 is located on both sides of the ship's side in an open a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com