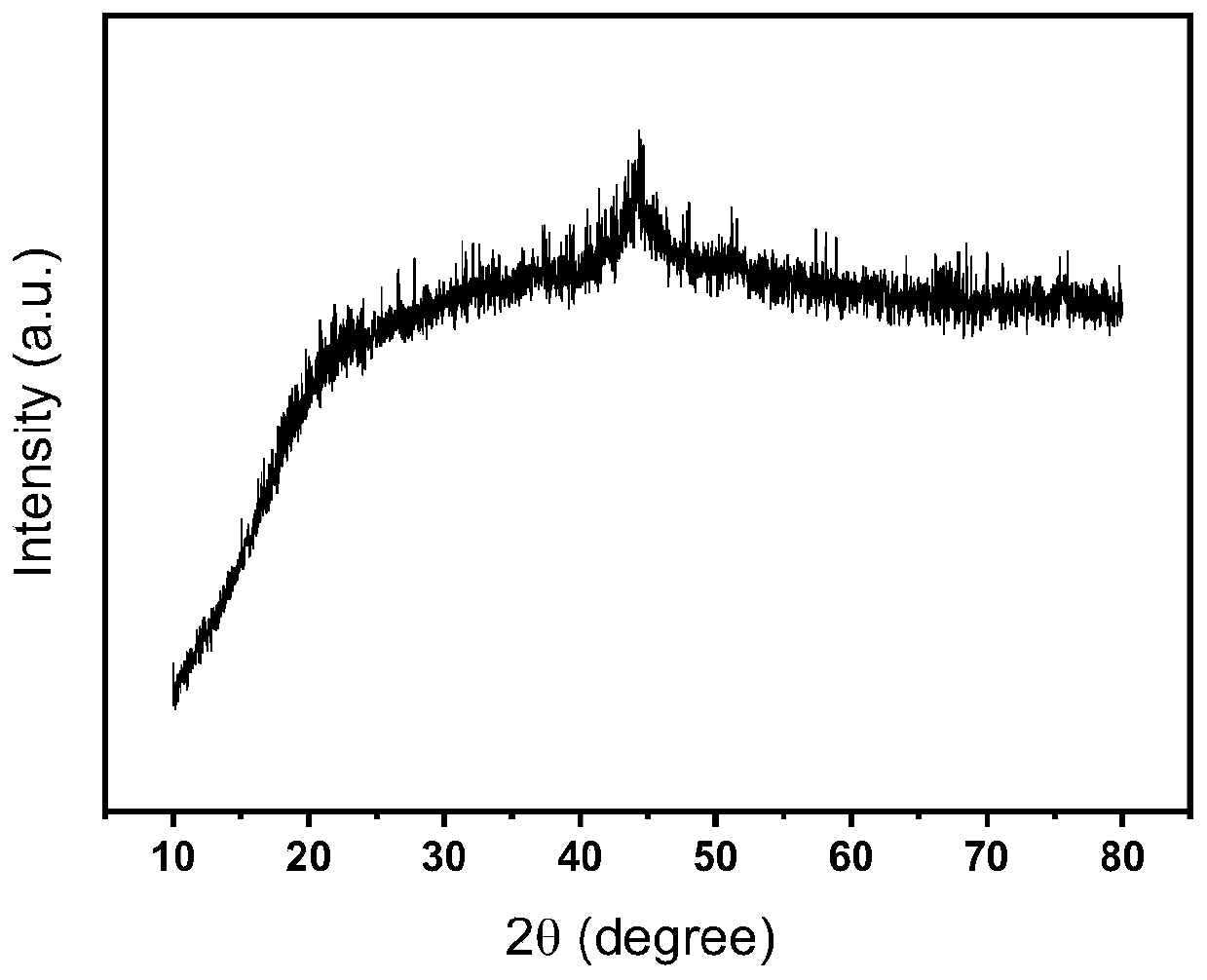

Lignite coke loaded nano-cobalt composite catalyst and preparation method thereof

A composite catalyst, nano-cobalt technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of catalyst deactivation and preparation cost, and achieve high added value utilization and high specific surface area. , the effect of low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

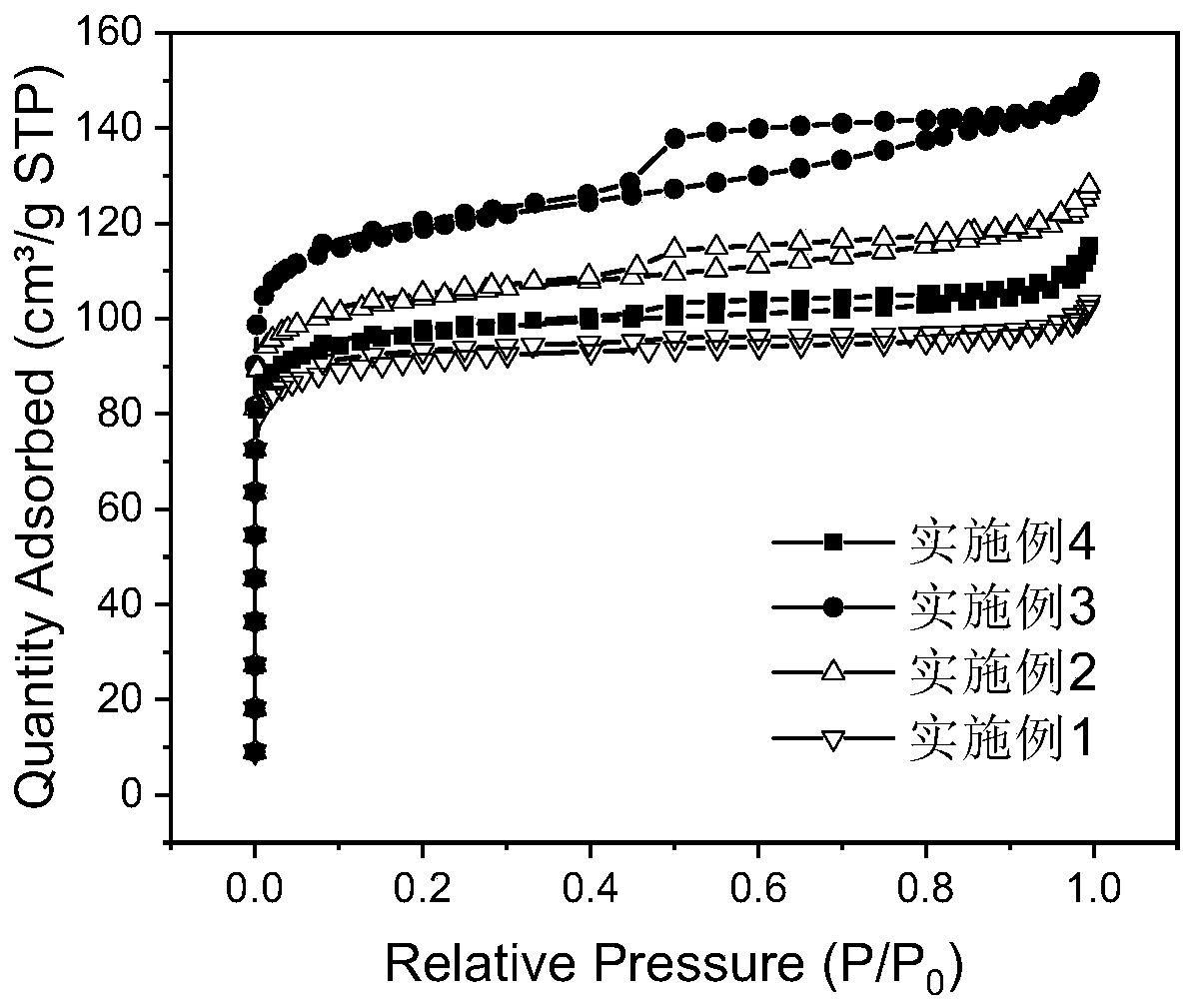

Embodiment 1

[0035] A lignite coke-loaded nano-cobalt composite catalyst, which is specifically prepared by the following method:

[0036] 1) crushing and sieving the original lignite block to obtain lignite particles;

[0037] 2) Weigh 2g of lignite particles and disperse them into 100g of ethanol. After ultrasonic dispersion treatment for 5min, add 4.93g of Co(NO 3 ) 2 Ethanol solution (20wt%), wherein, Co(NO 3 ) 2 The feed ratio of cobalt and lignite particles in the ethanol solution is 10wt%, and the ultrasonic dispersion treatment is continued for 5 minutes; the mixed solution obtained by ultrasonic dispersion is transferred to the stirrer, and stirred in a water bath at 45° C. for 2 hours, so that most of the ethanol is volatilized. Cool down to room temperature, continue to stir until the ethanol is completely volatilized, and then vacuum-dry at 45°C for 10 hours to obtain solid substance A;

[0038] 3) The solid material A was pyrolyzed at 700° C. for 2 h under an Ar atmosphere...

Embodiment 2

[0049] A lignite coke-loaded nano-cobalt composite catalyst, which is specifically prepared by the following method:

[0050] 1) crushing and sieving the original lignite block to obtain lignite particles;

[0051] 2) Weigh a certain amount of lignite particles, add them to 2mol / L nitric acid solution, stir in a water bath at 50°C for 2 hours, filter the mixture with suction, wash with deionized water several times, and place the solid sample obtained after washing at 120 Drying at ℃ to obtain acid-washed lignite particles;

[0052] 3) Weigh 2g of acid-washed lignite particles and disperse them into 100g of ethanol. After ultrasonic dispersion treatment for 5min, add 4.93g of Co(NO 3 ) 2 Ethanol solution (20wt%), wherein, Co(NO 3 ) 2 The feed ratio of cobalt and lignite particles in the ethanol solution is 10wt%, and the ultrasonic dispersion treatment is continued for 5 minutes; the mixed solution obtained by ultrasonic dispersion is transferred to the stirrer, and stirre...

Embodiment 3

[0064] The difference between this embodiment and Example 2 is: in the preparation process of the lignite coke-loaded nano-cobalt composite catalyst of the present embodiment, Co(NO 3 ) 2 The add-on of ethanol solution (20wt%) is 2.47g, at this moment, Co(NO 3 ) 2 The feed ratio of cobalt in the ethanol solution to the acid-washed lignite particles is 5wt%, and the others are the same as in Example 2.

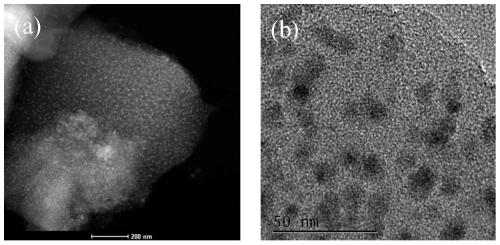

[0065] The TEM test and cobalt particle size statistics of the lignite coke-supported nano-cobalt composite catalyst in this embodiment were carried out.

[0066] It can be known from tests that the average size of cobalt particles in the lignite coke-supported nano-cobalt composite catalyst of this embodiment is 5 nm.

[0067] O 2 TG test of atmosphere.

[0068] It can be seen from the calculation of the test results that the cobalt loading amount (cobalt: lignite coke) in the lignite coke-supported nano-cobalt composite catalyst of this embodiment is 9 wt%.

[0069] Nit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com