Processing method for preventing pad from falling off in packaging process of multilayer thick circuit board

A processing method and circuit board technology, which can be used in multilayer circuit manufacturing, printed circuit manufacturing, printed circuit manufacturing, etc., and can solve the problems of reduced array density, wasted cost, and increased pad size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

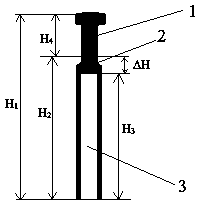

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

[0018] A processing method for solving the problem of pad drop in the packaging process of a multilayer thick circuit board. The multilayer thick circuit board is provided with an all-copper via hole 1, and a back-drilled hole 2 arranged at the all-copper via hole 1, including The process is as follows: fill the back-drilled hole 2 with resin, and back-drill air holes 3 at the resin after the resin is cured.

[0019] The diameter of the air hole 3 is smaller than that of the back-drilled hole 2 .

[0020] There is a height difference between the air hole 3 and the back-drilled hole 2, and the height difference is the thermal expansion compensation height ΔH.

[0021] The thermal expansion compensation height ΔH = back drilling height H 2 -Stomatal height H 3 ;

[0022] The stomatal height H 3 ={[(Expansion volume of residual copper in via + CTE expansion volume be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com