Underwater wet-type electric connector capable of being plugged and unplugged in electrified mode

A live plug-in, wet-type technology, applied in the direction of connection, two-part connection device, and parts of the connection device, etc., can solve the electric shock accident of the water surface power supply part, the inability to realize live plug-in and plug-in, and the short circuit of the pin circuit, etc. Cost-effective assembly and connection, cost-effective disassembly and replacement, and the effect of preventing accidental interruption of the circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

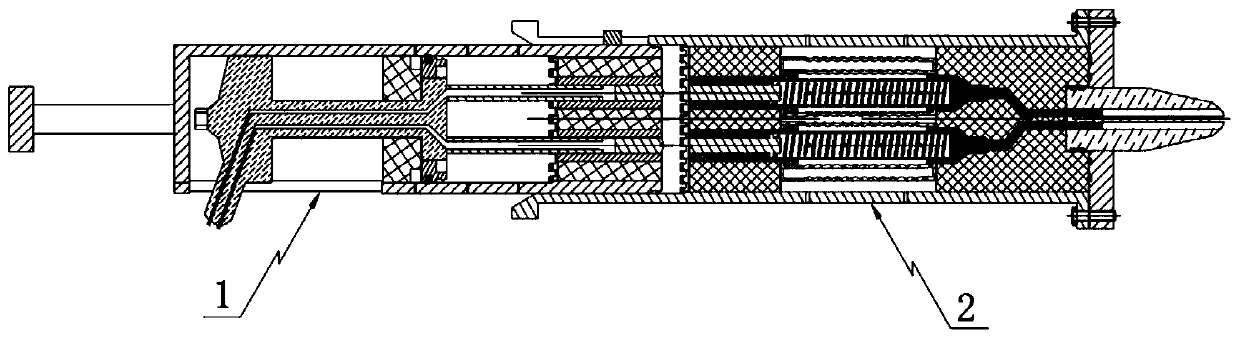

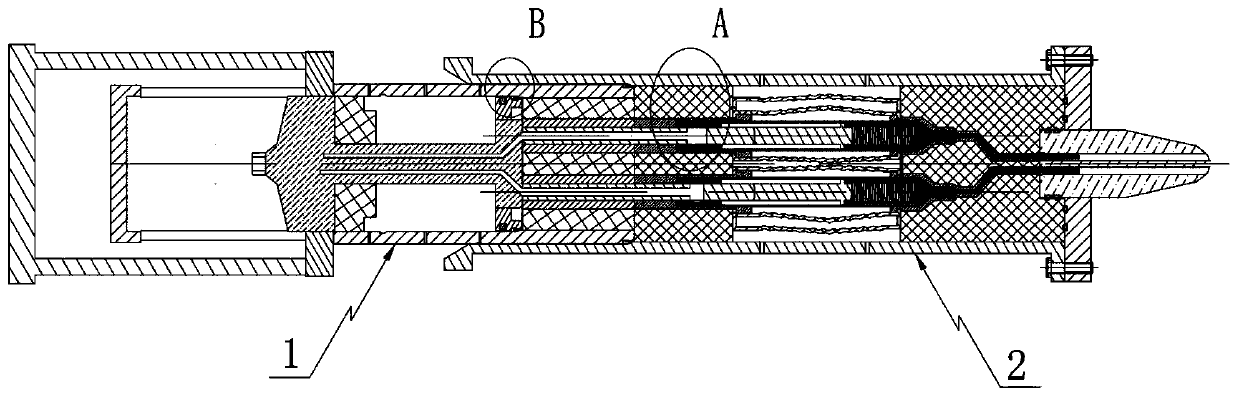

[0042] Such as Figure 1~2 As shown, the present invention includes a male plug body 1 and a female socket body 2 .

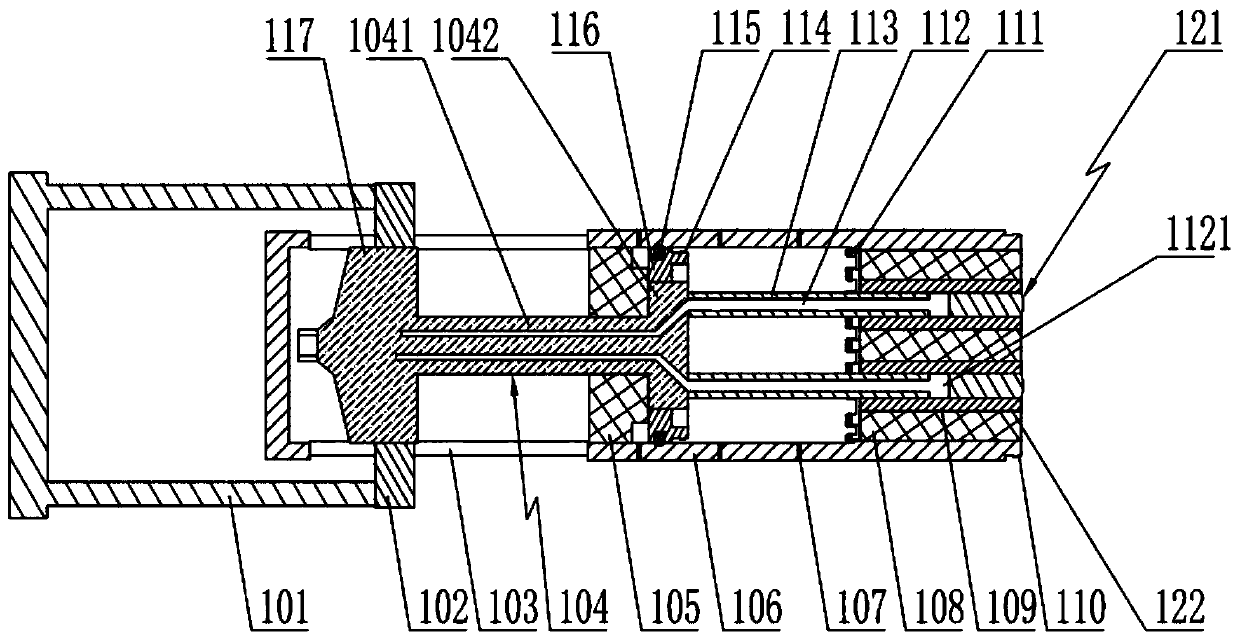

[0043] Such as Figure 3-4 As shown, the structure of the male plug body 1 is: comprising a first shell 106, the first shell 106 is a hollow cylindrical structure with an opening on the head, and the outer wall of the head of the first shell 106 is provided with a ring-shaped The first-level locking groove 110, the inner wall of the head of the first housing 106 is matched with the end support block 108, and the middle part of the inner cavity of the first housing 106 is provided with a pin assembly along the axial direction, and one end of the pin assembly is supported by the end The block 108 is plugged in, and the other end is slidably positioned in the inner cavity of the first housing 106 through the sliding lock ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com