A silicon-based @titanium niobium oxide core-shell structure negative electrode material and its preparation method

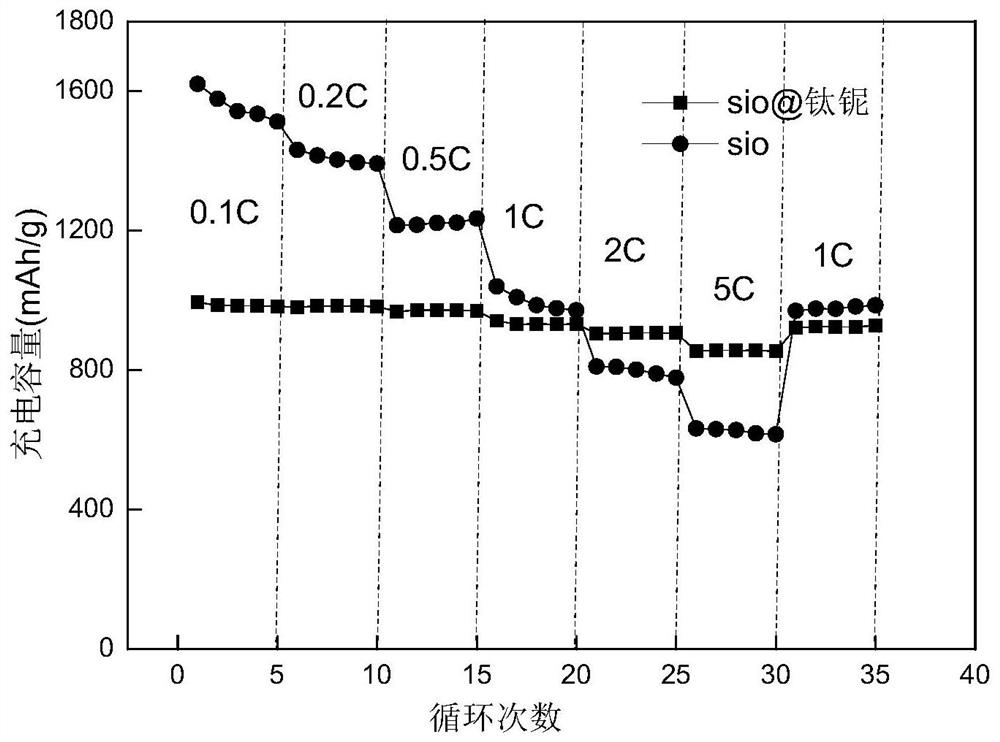

A technology of titanium niobium oxide and negative electrode materials, applied in the direction of negative electrodes, structural parts, active material electrodes, etc., can solve the problems of electrical conductivity, first-time Coulombic efficiency cycle performance defects, etc., and achieve reduced high-temperature solid phase reaction time and high capacity , the effect of inhibiting volume expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) Put 1.53g of titanium dioxide into the dispersion tank, add 9.78g of niobium pentoxide (according to the molar ratio of titanium source and niobium source is 1:1.92); 200ml of deionized water, disperse and stir for 30min;

[0039] (2) Transfer the above-mentioned mixed solution to the dispersion tank of a sand mill, and after ball milling for 60 minutes, take the slurry and carry out a particle size test, and the particle size is 79nm;

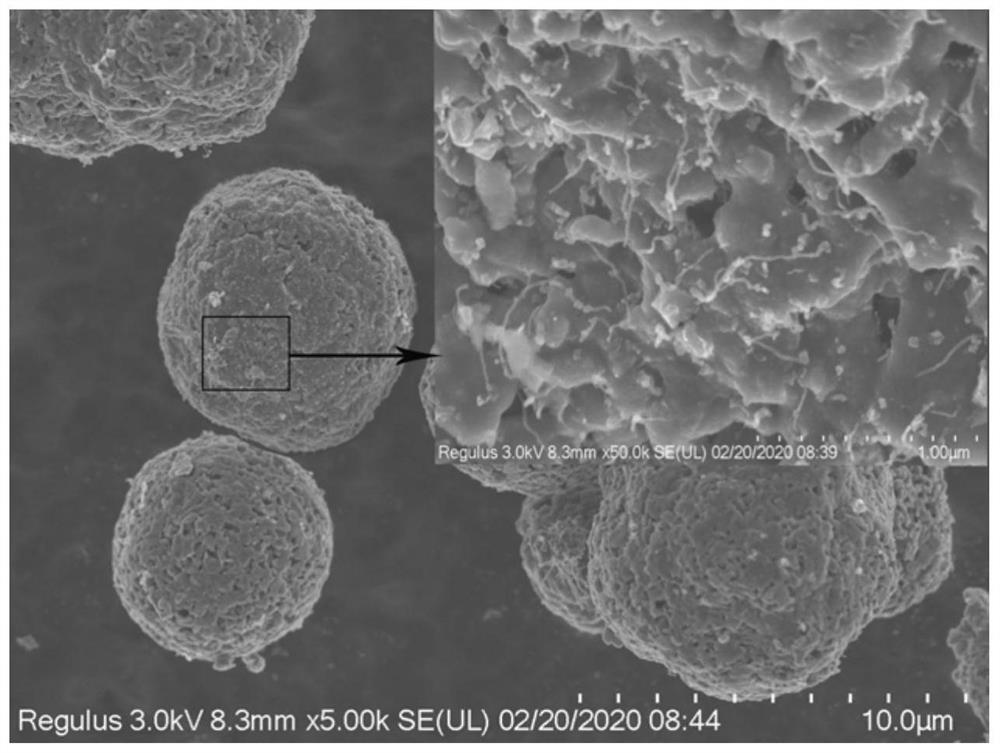

[0040] (3) Take 130g of sio with a particle diameter of 5um, add it to the dispersion tank of the above-mentioned sand mill, and continue the ball milling for 2min to export the mixture;

[0041] (4) Use a low-temperature spray dryer to dry, the inlet temperature is 50°C, the feed rate is 50ml / min; the inlet pressure is 6MPa; the sio-titanium niobium oxide precursor is obtained;

[0042] (5) Forging the above-mentioned sio-titanium niobium oxide precursor: use argon protection, raise the temperature to 1100°C at a rate of 50°C / min, ...

Embodiment 2

[0050] (1) Put 1.82g of metatitanic acid into a dispersion tank, add 9.49g of niobium pentoxide (according to the molar ratio of titanium source and niobium source is 1:1.92); 200ml of deionized water, disperse and stir for 30min;

[0051] (2) Transfer the above-mentioned mixed solution to the dispersion tank of a sand mill, and after ball milling for 60 minutes, take the slurry and carry out a particle size test, and the particle size is 80nm;

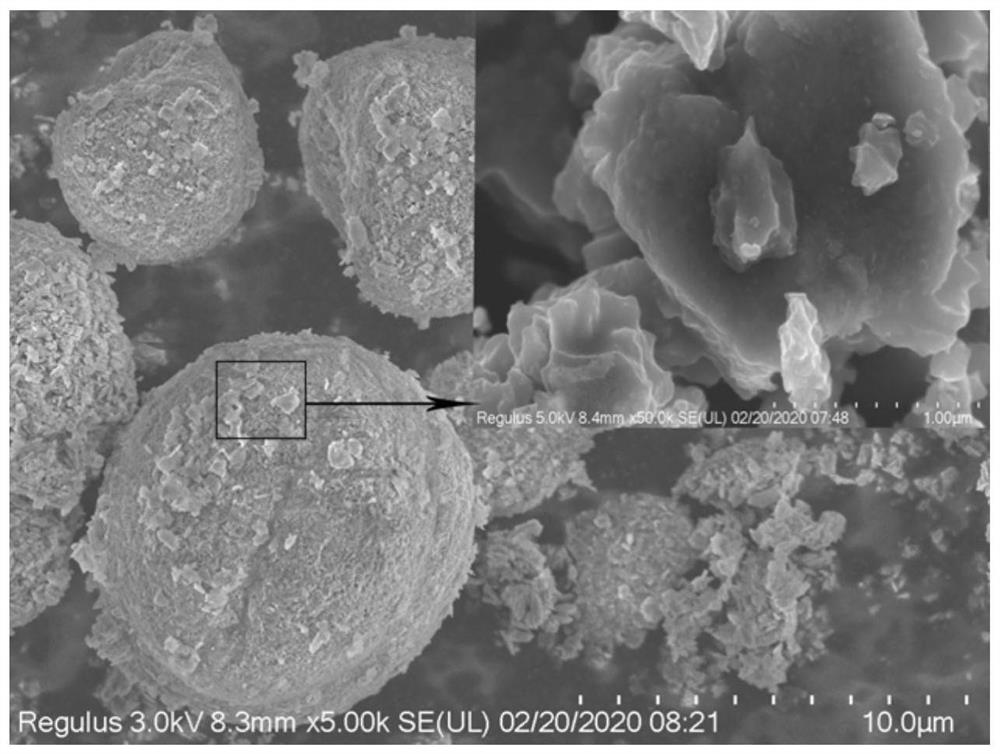

[0052] (3) Take 130g of sio with a particle diameter of 5um, add it to the dispersion tank of the above-mentioned sand mill, and continue the ball milling for 2min to export the mixture;

[0053] (4) Use a low-temperature spray dryer to dry, the inlet temperature is 50°C, the feed rate is 50ml / min; the inlet pressure is 6MPa; the sio-titanium niobium oxide precursor is obtained;

[0054] (5) Forging the above-mentioned sio-titanium niobium oxide precursor: use argon protection, raise the temperature to 1100°C at a rate of 50°C / min, an...

Embodiment 3

[0056] (1) Put 1.4g of metatitanic acid into a dispersion tank, add 7.3g of niobium pentoxide (according to the molar ratio of titanium source and niobium source is 1:1.92); 150ml of deionized water, disperse and stir for 30min;

[0057] (2) Transfer the above-mentioned mixed solution to the dispersion tank of the sand mill, after ball milling for 50min, take the slurry and carry out the particle size test, the particle size is 85nm;

[0058] (3) Take 100g of si with a particle size of 200nm, add it to the dispersion tank of the above-mentioned sand mill, and continue the ball milling for 2min to export the mixture;

[0059] (4) Use a low-temperature spray dryer to dry, the inlet temperature is 50°C, the feed rate is 50ml / min; the inlet pressure is 6MPa; the si-titanium niobium oxide precursor is obtained;

[0060] (5) Forging the above si-titanium niobium oxide precursor: use argon protection, raise the temperature to 1100°C at a rate of 50°C / min, and keep it for 30 minutes; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com