A composite shielding structure suitable for electric vehicle wireless power supply system

A technology for wireless power supply and electric vehicles, applied in electric vehicle charging technology, electric vehicles, parts of transformers/inductors, etc., can solve problems such as bulky structure, affecting transmission efficiency, and underutilization of magnetically permeable materials, etc., to simplify production Process, save material, control the effect of temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035]Specific examples of the present invention are given below. The specific embodiments are only used to further describe the present invention in detail, and do not limit the protection scope of the claims of the present application.

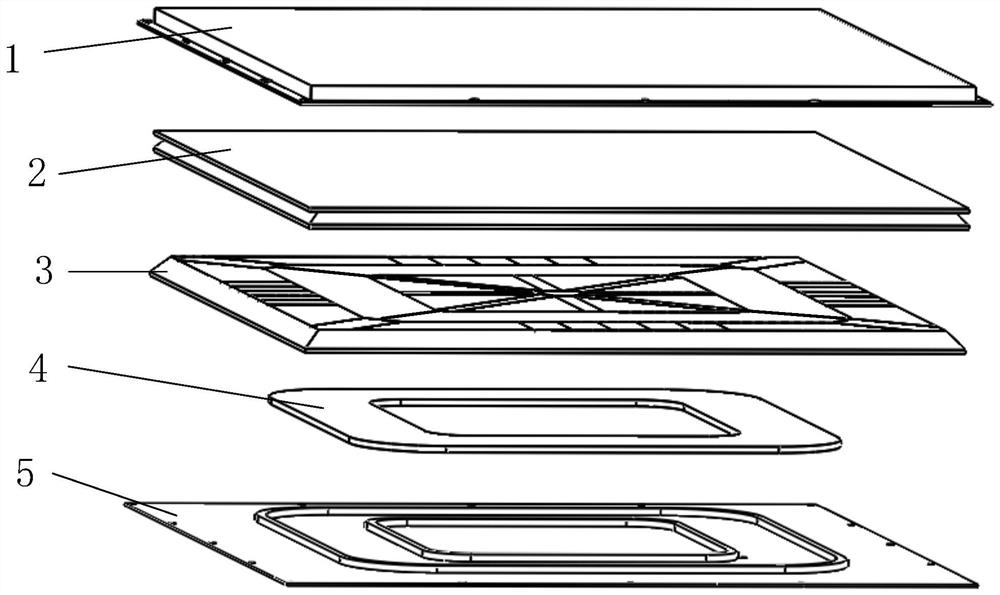

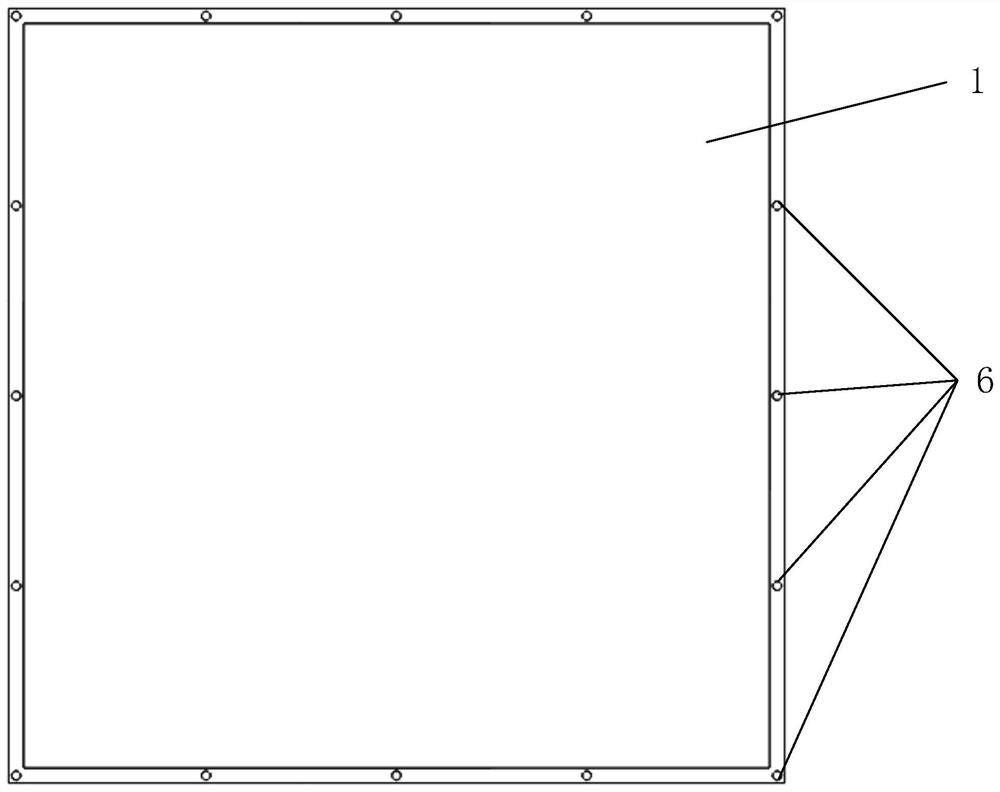

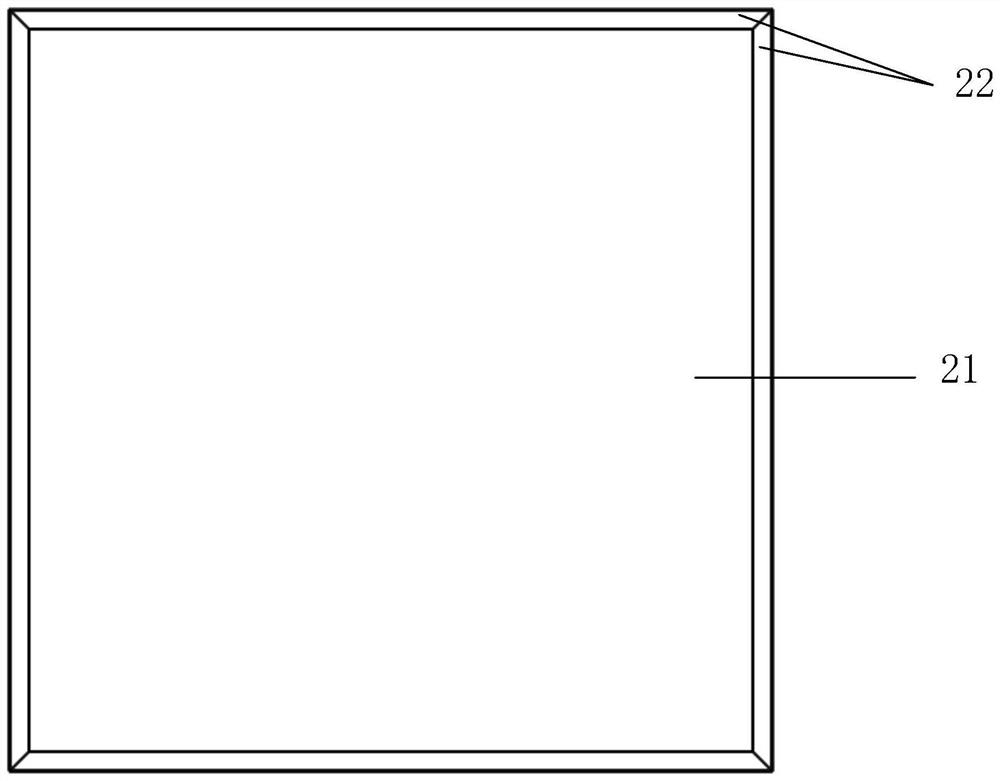

[0036] The invention provides a composite shielding structure suitable for electric vehicle wireless power supply system, the structure is as figure 1 As shown, it includes an aluminum cover 1, an alumina ceramic heat conducting plate 2, a magnetic material shielding plate 3, a receiving coil 4 and a bakelite substrate 5;

[0037] The relative position of the composite shielding structure and the schematic diagram of the overall structure are as follows: figure 1 , figure 2 As shown, the bakelite substrate 5 is located at the bottom, the receiving coil 4 is located above the bakelite substrate 5, and the receiving coil 4 is placed between the inner frame boundary 51 of the substrate and the outer frame boundary 52 of the substrate; the ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com