High-sensitivity electric field sensor formed by polyamine molecule modified carbon fibers

An electric field sensor, high-sensitivity technology, used in instruments, scientific instruments, electrical/magnetic exploration, etc., can solve the problems of difficult to detect low-frequency weak signals, poor electrode stability, reduced sensitivity, etc., to achieve a wide range of applications, low cost, The effect of stabilizing physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

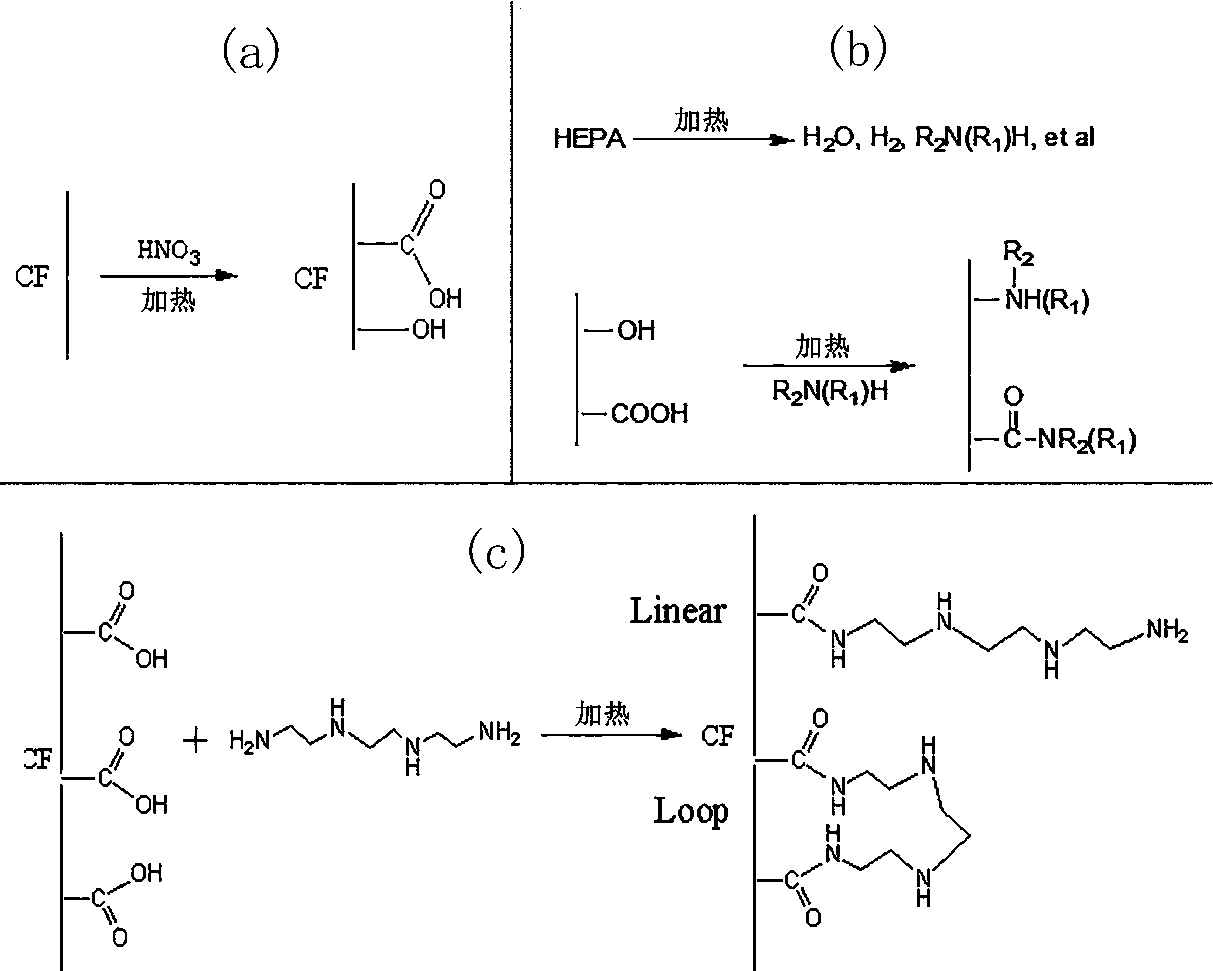

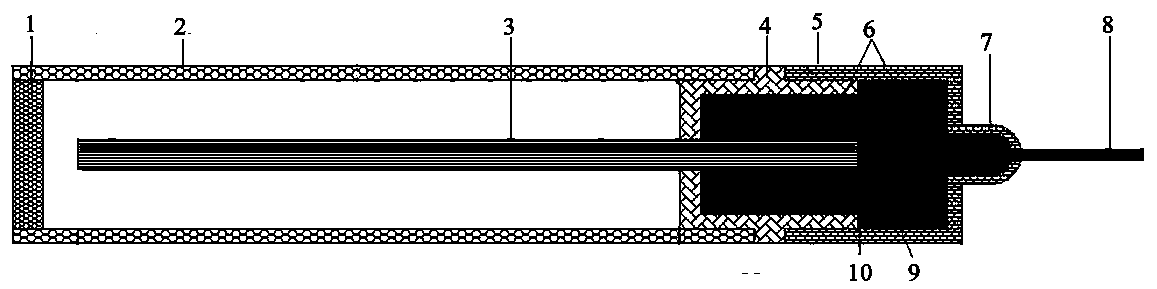

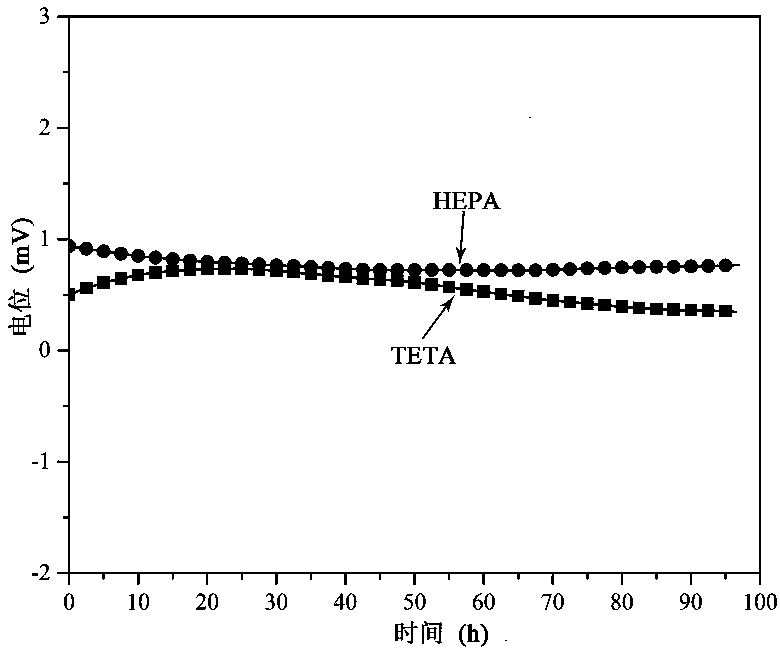

[0039] Such as figure 1 As shown, the present invention prepares a carbon fiber rich in nitrogen groups: first, a certain amount of carbon fiber is added to the nitric acid solution (the concentration of nitric acid is 8 mol / L ~ 16 mol / L), and the temperature is oscillated at 85 ℃ ~ 95 ℃ React for 2 h to 4 h, wash with water several times until the washing solution is neutral, and dry in a blast drying oven at 60 °C to 80 °C to obtain carbon oxide fibers. Then put a certain amount of oxidized carbon fiber into the aqueous solution of triethylenetetramine (TETA) (the concentration of TETA is 0.5 g / L ~ 1 g / L) and ultrasonic for 30 min ~ 60 min, so that the carbon fiber and triethylenetetramine Fully contact; then take out the carbon fiber coated with triethylenetetramine molecule (TETA) solution and put it in a box-type resistance furnace heated to 350 ℃ ~ 450 ℃ for 10 min ~ 15 min; finally put the carbon fiber after heat treatment in boiling water The clean carbon fiber was ob...

Embodiment 2

[0041] Such as figure 1 As shown, the present invention prepares a carbon fiber rich in nitrogen groups: first, a certain amount of carbon fiber is added to the nitric acid solution (the concentration of nitric acid is 8 mol / L ~ 16 mol / L), and the temperature is oscillated at 85 ℃ ~ 95 ℃ React for 2 h to 4 h, wash with water several times until the washing solution is neutral, and dry in a blast drying oven at 60 °C to 80 °C to obtain carbon oxide fibers. Then put a certain amount of oxidized carbon fiber into the aqueous solution of polyethylene polyamine (HEPA) (the concentration of HEPA is 0.5 g / L ~ 1 g / L) and sonicate for 30 min ~ 60 min to make the carbon fiber and polyethylene polyamine Fully contact; then take out the carbon fiber coated with polyethylene polyamine molecule (HEPA) solution and put it into a box-type resistance furnace heated to 550 ℃ ~ 650 ℃ for 2 min ~ 5 min; finally heat treated carbon fiber with Clean carbon fibers were obtained by washing with boil...

Embodiment 3

[0043]The present invention prepares a carbon fiber rich in nitrogen groups: first, a certain amount of carbon fiber is added to a nitric acid solution (the concentration of nitric acid is 8 mol / L ~ 16 mol / L), and the reaction is carried out at a constant temperature of 85 ℃ ~ 95 ℃ for 2 h ~ 4 h, washed with water several times until the washing solution is neutral, and dried in a blast drying oven at 60 ℃ ~ 80 ℃ to obtain carbon oxide fibers. Then put a certain amount of carbon oxide fiber into the ethanol suspension of melamine (the mass ratio of melamine to ethanol is 1:5~10), stir at room temperature for 5~10 hours, and then boil the mixture to completely evaporate the ethanol; The remaining carbon fibers were heat-treated (300 °C ~ 600 °C) for a period of time (0.5 h ~ 3 h); finally, the heat-treated carbon fibers were rinsed with boiling water several times to obtain clean carbon fibers, which were dried and used as electrode materials for electric field sensors.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com