Bedding rock surface bridge steel pipe support foundation and treatment method thereof

A technology of bridge foundation and treatment method, which is applied in infrastructure engineering, excavation, construction, etc., and can solve problems such as long construction period of mechanical drilling, high safety risk of manual drilling, and loose rock surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

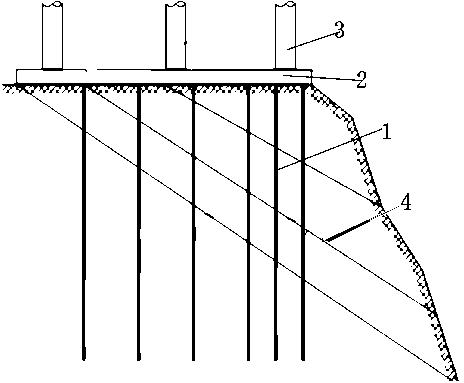

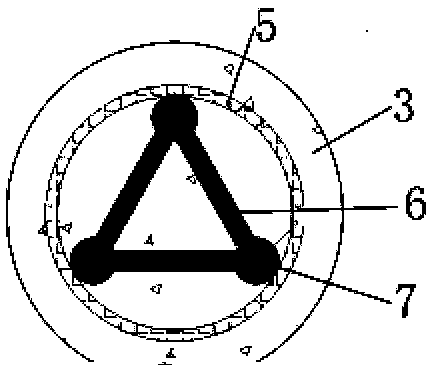

[0031] see Figure 1-5 , the present invention provides a technical solution: a bridge steel pipe support on the bedding rock surface, including a platform 2, the top pin of the platform 2 is connected with a micro pile 3, and the bottom of the platform 2 is fixedly installed with a steel pipe 1. A cable 4 is fixedly installed on the bottom of the platform 2 , concrete 5 is poured inside the micro pile 3 , and a support rod 6 is fixedly installed inside the concrete 5 through a connector 7 .

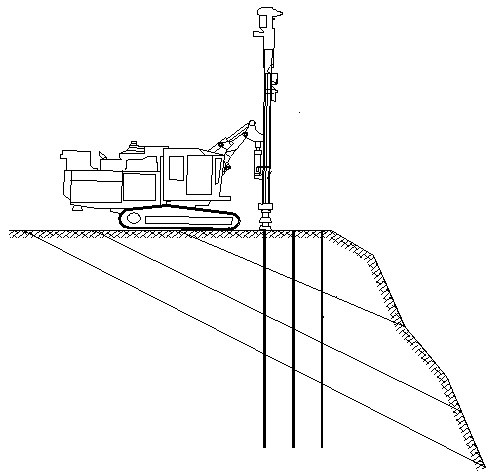

[0032] A method for treating the foundation of a bridge on a bedding rock surface, including the load of the upper column of the support, which is distributed to the micro-pile through the cap 2, and then transferred to the stable bedrock by the micro-pile 3. On the other hand, the micro-pile 3 is pinned in series It can play the role of retaining and anti-sliding reinforcement for unstable slopes. The operation steps are as follows:

[0033] S1. Work before hole formation: measure and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com