Process for producing aluminum medium gaugefoil through 8150 alloy

A technology of aluminum foil and alloy, applied in the direction of manufacturing tools, metal rolling, furnace types, etc., can solve the problems of poor mechanical properties, manganese segregation, unusable and other problems of finished products, and achieve the effect of high yield rate, excellent performance, and not easy to break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

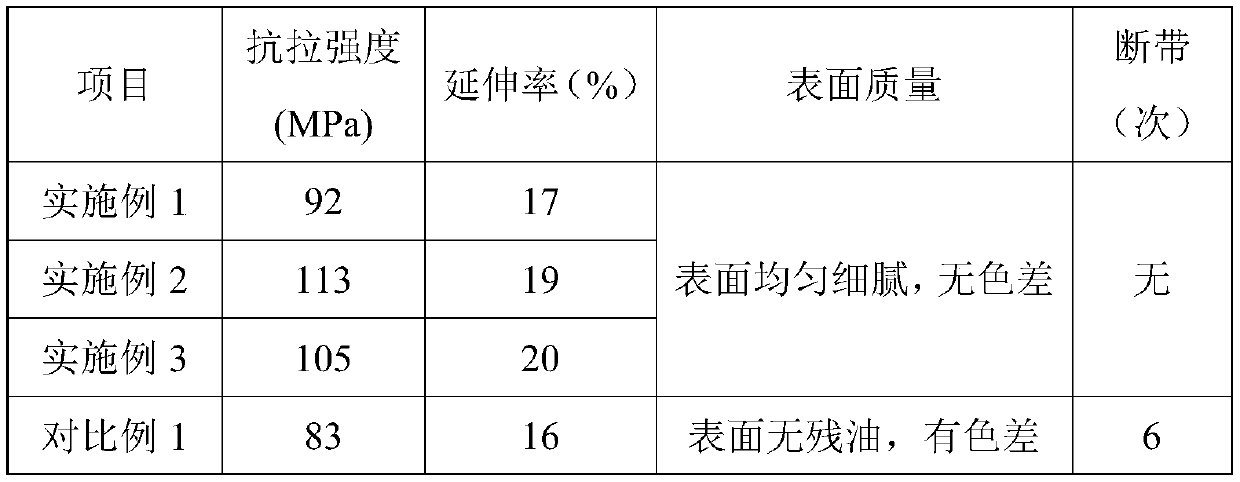

Examples

Embodiment 1

[0037] A kind of 8150 alloy produces the technique of single zero aluminum foil, comprises the following steps:

[0038] Step 1. Ingredients: Fe: 1.24%, Si: 0.14%, Cu: 0.03%, Mn: 0.65%, Ti: 0.020%, Cr: 0.02%, Zn: 0.03%, Cd: 0.001%, Li: 0.0002% , Na: 0.0005%, Pb: 0.005%, Mg: 0.01%, Sn: 0.005%, Co: 0.0002%, Zr: 0.0002%, the remaining amount is Al, and the weight percentage is used to configure the raw materials;

[0039] Step 2. Melting: Add the above-mentioned prepared raw materials into the flame reverberatory furnace, heat up and melt, stir 3 times during the melting process, and stir for 5 minutes each time, so that the material and liquid in the furnace are evenly mixed;

[0040] Step 3. Refining: The temperature of the material liquid after stirring evenly is at 740-750°C, stirring and performing the first refining for 10 minutes, and then removing slag; then raising the temperature to 760-770°C for the second refining, the time is 20min, the pressure is controlled at 0.5...

Embodiment 2

[0047] A kind of 8150 alloy produces the technique of single zero aluminum foil, comprises the following steps:

[0048] Step 1. Ingredients: Fe: 1.22%, Si: 0.13%, Cu: 0.01%, Mn: 0.58%, Ti: 0.015%, Cr: 0.005%, Zn: 0.005%, Cd: 0.0001%, Li: 0.00002% , Na: 0.00005%, Pb: 0.0005%, Mg: 0.001%, Sn: 0.005%, Co: 0.00002%, Zr: 0.00002%, the remaining amount is Al, and the weight percentage is used to configure the raw materials;

[0049] Step 2. Melting: Add the above-mentioned prepared raw materials into the flame reverberatory furnace, heat up and melt, stir 3 times during the melting process, and stir for 4 minutes each time, so that the material and liquid in the furnace are evenly mixed;

[0050] Step 3. Refining: The temperature of the material liquid after stirring evenly is at 740-750°C, stirring and performing the first refining for 10 minutes, and then removing slag; then raising the temperature to 760-770°C for the second refining, the time is 20min, the pressure is controll...

Embodiment 3

[0057] A kind of 8150 alloy produces the technique of single zero aluminum foil, comprises the following steps:

[0058] Step 1. Ingredients: Fe: 1.25%, Si: 0.16%, Cu: 0.03%, Mn: 0.60%, Ti: 0.025%, Cr: 0.02%, Zn: 0.03%, Cd: 0.001%, Li: 0.00008% , Na: 0.0005%, Pb: 0.005%, Mg: 0.01%, Sn: 0.005%, Co: 0.0002%, Zr: 0.00008%, the remaining amount is Al, and the weight percentage is configured as a raw material;

[0059] Step 2. Melting: Add the above-mentioned prepared raw materials into the flame reverberatory furnace, heat up and melt, stir 4 times during the melting process, and stir for 6 minutes each time, so that the material and liquid in the furnace are evenly mixed;

[0060] Step 3. Refining: The temperature of the material liquid after stirring evenly is at 740-750°C, stirring and performing the first refining for 10 minutes, and then removing slag; then raising the temperature to 760-770°C for the second refining, the time is 20min, the pressure is controlled at 0.50Mpa;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com