Building wall surface plastering-free anti-crack technology

A building, plaster-free technology, used in building construction, construction, covering/lining, etc., can solve problems affecting project completion acceptance, wall cracking, wall hollowing, etc., to achieve two-way affinity and leveling ability. , Strong acid and alkali corrosion resistance, avoid the effect of empty drum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

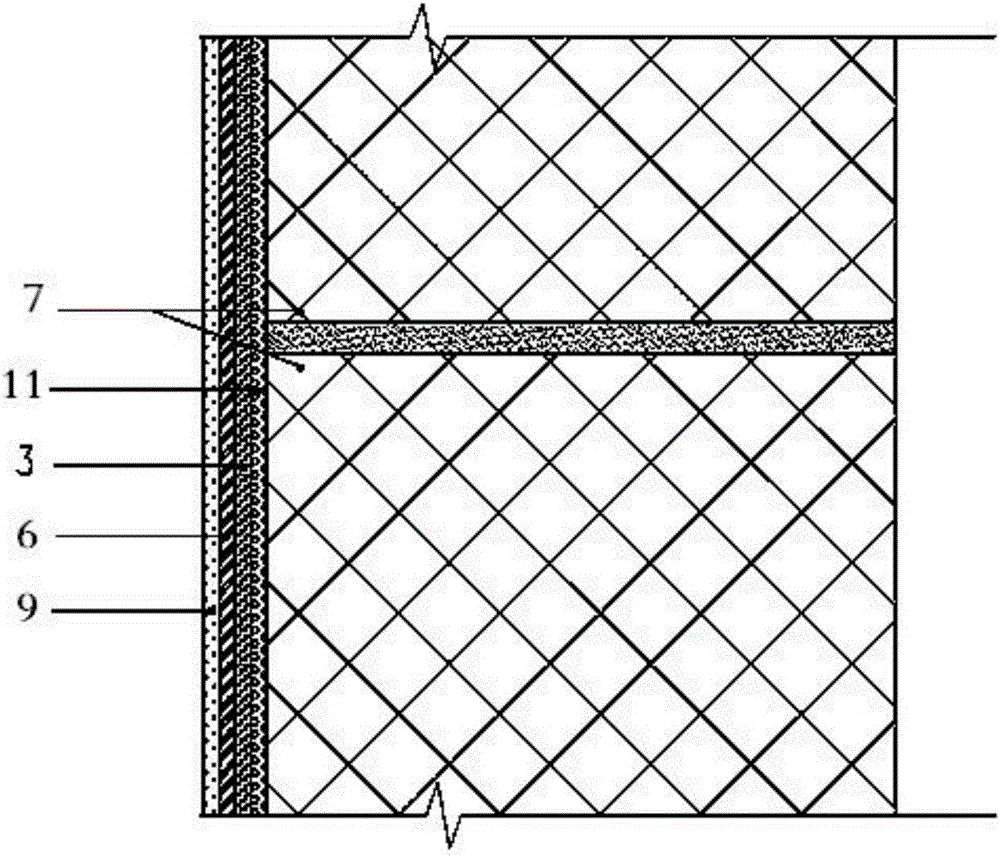

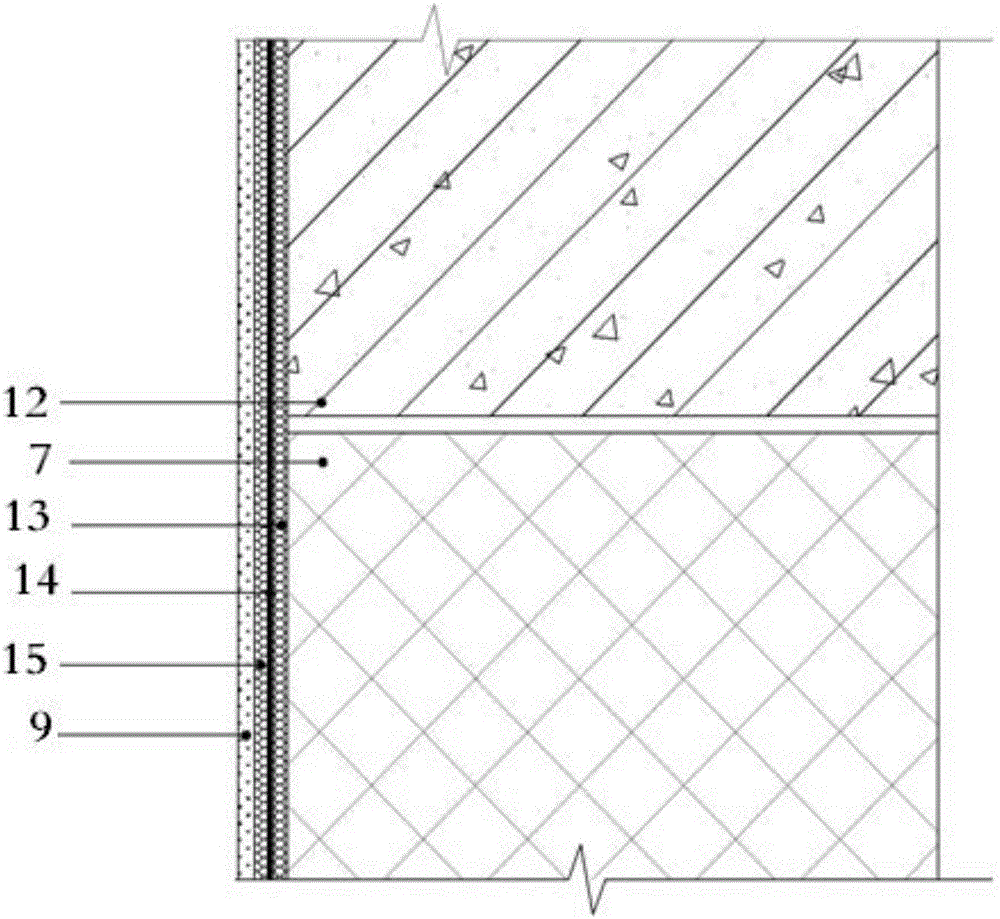

[0015] The process of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0016] The invention relates to a plaster-free anti-cracking process for the wall surface of a building. In the process, different construction processes are respectively adopted at the internal and external corners of the building, the masonry wall surface, and the joint between concrete and masonry.

[0017] like figure 1 The structure of the free plastering and straight yin and yang corners of the building wall shown is that inside the yin and yang corners of the building 1 and outside the yang corners 2, on the bottom anti-cracking putty layer 3 applied on the wall, the corners are pasted respectively. An L-shaped internal corner strip 4 and a L-shaped external corner strip 5 are installed on the cross-section, and a surface leveling and anti-cracking putty layer 6 is coated and scraped outside the internal corner strip 4 and the exte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com