Butylhydroxy aluminum-free propellant and preparation method thereof

A propellant and adhesive technology, which is applied in the field of butylated hydroxyaluminum-free propellant and its preparation, can solve the problems of increasing the smoke characteristic signal of the propellant, reducing the energy performance of the propellant, and deteriorating the process performance of the propellant. Good speed pressure index, reduced primary smoke generation, stable combustion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Propellant composition (mass percentage) is as shown in Table 1:

[0034] Table 1

[0035]

[0036]

[0037] (2) Propellant properties are as shown in Table 2:

[0038] Table 2

[0039]

Embodiment 2

[0041] (1) Propellant composition (mass percentage) is as shown in Table 3:

[0042] table 3

[0043]

[0044] (2) Propellant properties are as shown in Table 4:

[0045] Table 4

[0046]

[0047]

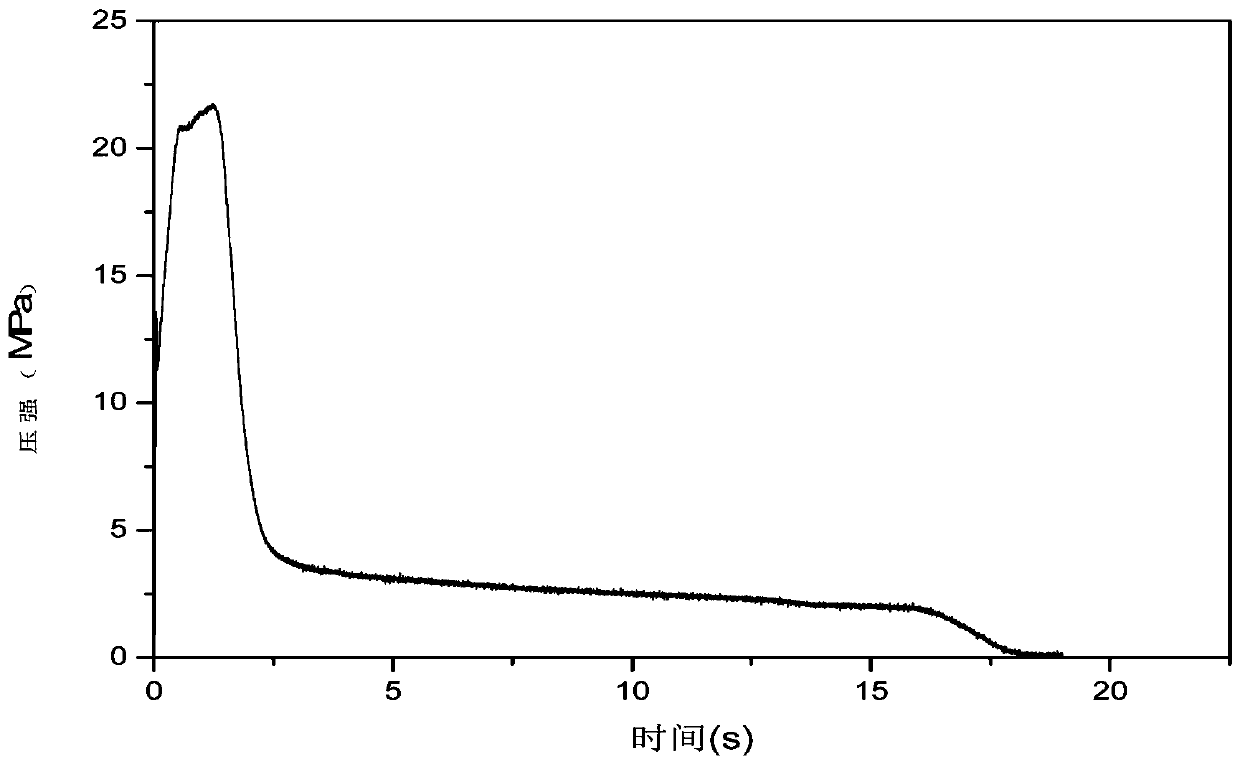

[0048] Wherein the reference propellant in embodiment 2 and adopt the propellant of formula of the present invention to make the engine ground test smog generation situation visual diagram such as figure 1 and figure 2 shown, from Figure 1 ~ Figure 2 It can be seen from the comparison that the amount of combustion smoke generated by the aluminum-free butylated hydroxy propellant of the present invention is significantly less than that of the reference propellant with an aluminum content of 8%.

Embodiment 3

[0050] (1) Propellant composition (mass percentage) is as shown in Table 5:

[0051] table 5

[0052]

[0053] (2) Propellant properties are shown in Table 6:

[0054] Table 6

[0055]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com