Core-shell type aluminum-coated perchlorate/catalyst composite microsphere and solid propellant based on microsphere

A technology of solid propellants and composite microspheres, applied in the field of solid propellants and composite solid propellants, can solve problems such as unsatisfactory results, and achieve the effects of avoiding friction, enhancing heat and mass transfer processes, and increasing specific impulse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] The preparation process can be divided into the following three steps:

[0056] S1: Add 2.5g of AP (ammonium perchlorate) to 15ml of distilled water, then add 2.5g of Al powder, after ultrasonic treatment for 10min, magnetically stir for 2h to obtain the precursor solution;

[0057] S2: Add 0.1 g of polyvinylpyrrolidone (PVP) to the precursor solution to adjust the viscosity of the precursor solution;

[0058] S3: Treat the precursor solution obtained in step S2 with a spray drying device, the inlet air temperature is 150°C, and the injection rate is 9ml min -1 , the fan is 35m 3 min -1 , to collect the resulting complex;

[0059] S4: The composite obtained in step S3 was placed in dichloromethane solvent and stirred for 12 hours, the solid was collected by filtration and freeze-dried for 24 hours to prepare composite microspheres Al@AP.

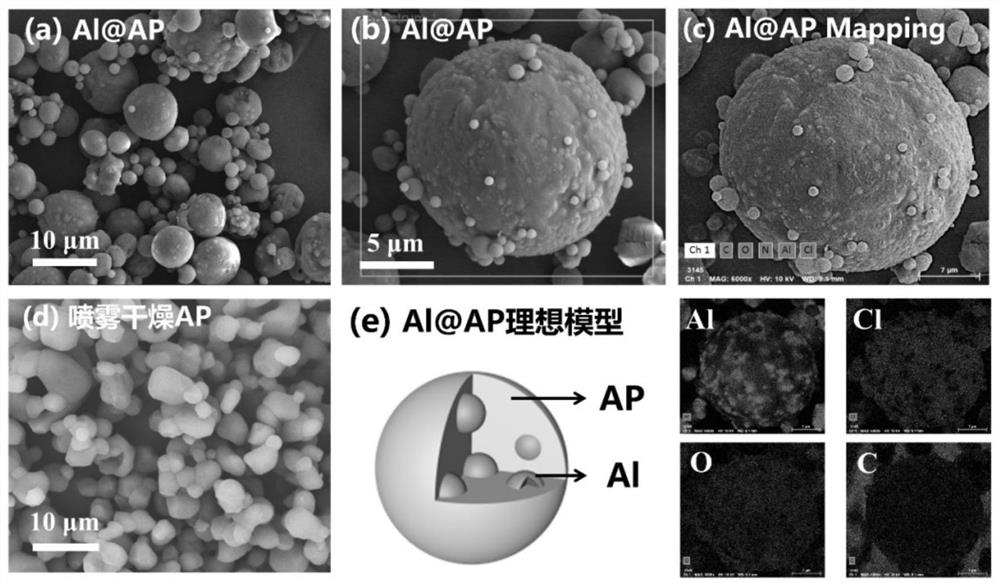

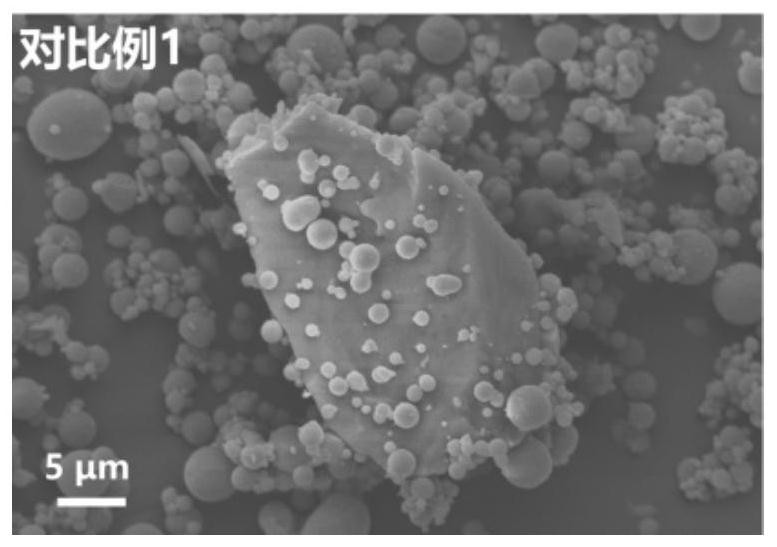

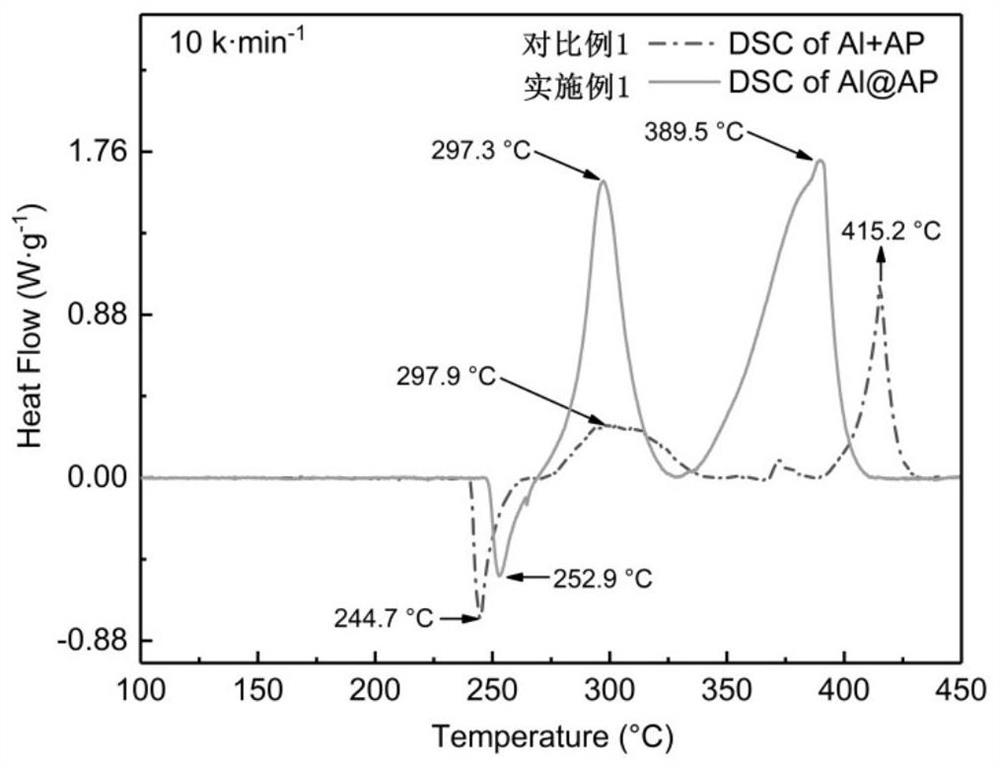

[0060] The particle size distribution result of embodiment 1 is as shown in table 1, D 50 is 5.09 μm. figure 1 It is the SEM-E...

Embodiment 2

[0065] Others are the same as in Example 1, and 0.28 g of CuO is added to the precursor solution in step S1 to obtain composite microspheres Al@AP / CuO.

[0066] The particle size distribution result of embodiment 2 is as shown in table 1, D 50 is 5.21 μm. Figure 4 It is the SEM-EDS picture of Example 2 and its ideal model. It can be seen that the Al@AP / CuO composite microsphere has a complete structure and a high degree of sphericity ( Figure 4 a and b), CuO is uniformly embedded inside the AP crystal ( Figure 4 c), its ideal model is as Figure 4 as shown in e.

Embodiment 3

[0071] Others are the same as in Example 1, add 0.28g of Fe to the precursor solution in step S1 2 o 3 , to obtain core-shell composite microspheres Al@AP / Fe 2 o 3 . The particle size distribution result of embodiment 3 is as shown in table 1, D 50 is 5.15 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com