Precision sprayer capable of controlling spraying amount and spraying frequency

A technology of ejection volume and frequency, applied in the direction of ejection device, liquid ejection device, etc., can solve the problem of insufficient precision of the nozzle, achieve the effect of clear pattern edge, ensure the spray shape, and improve the precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

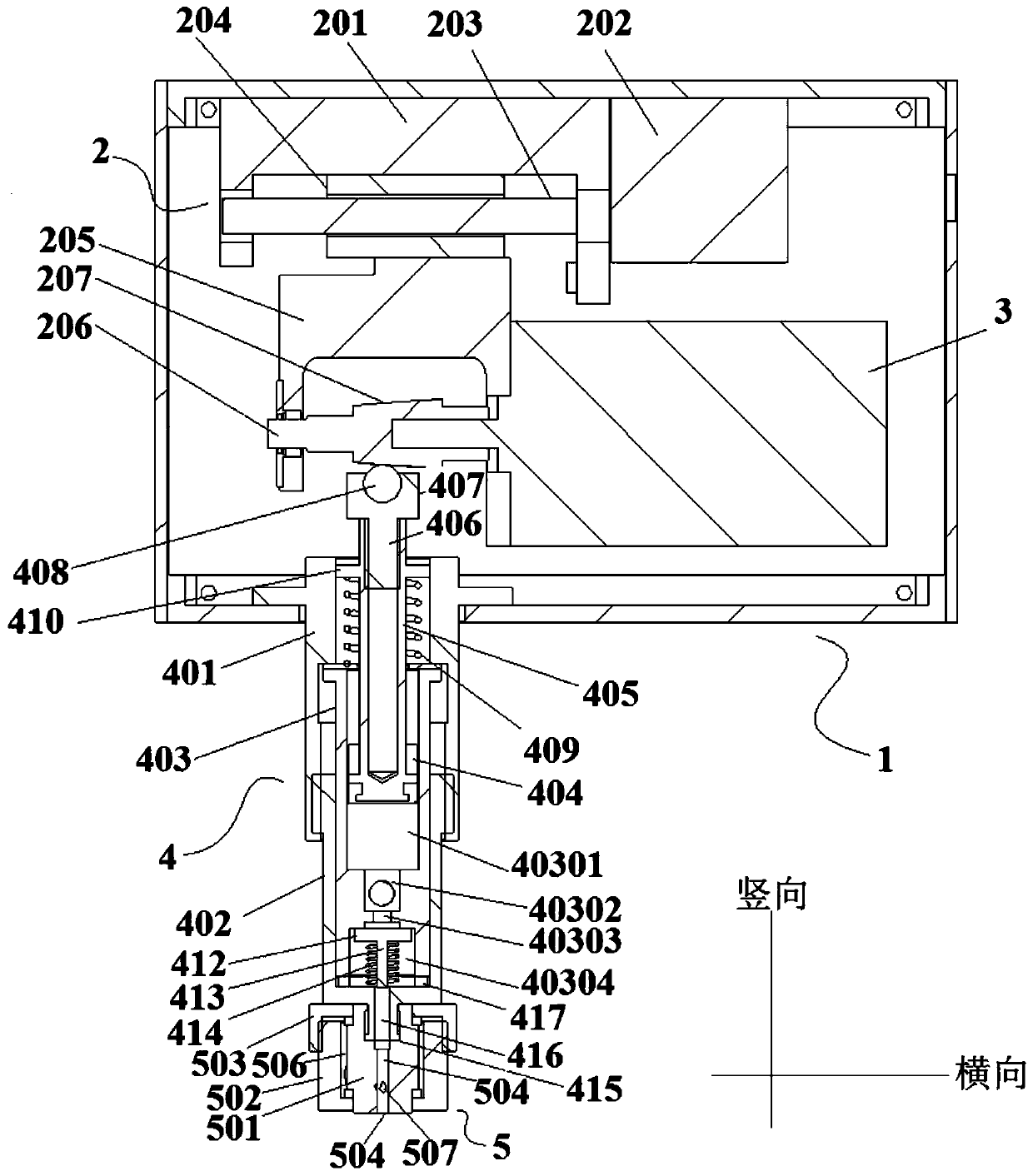

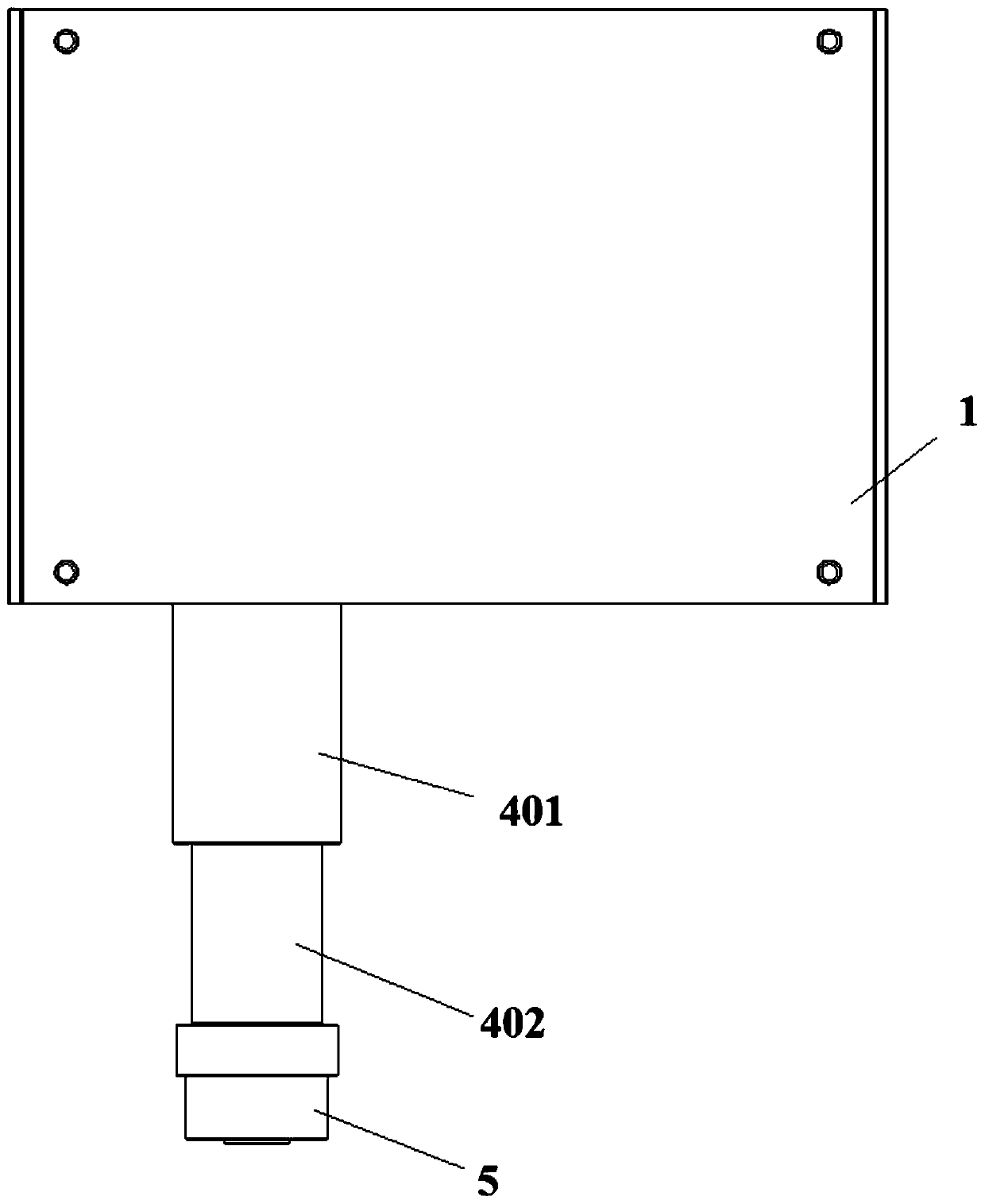

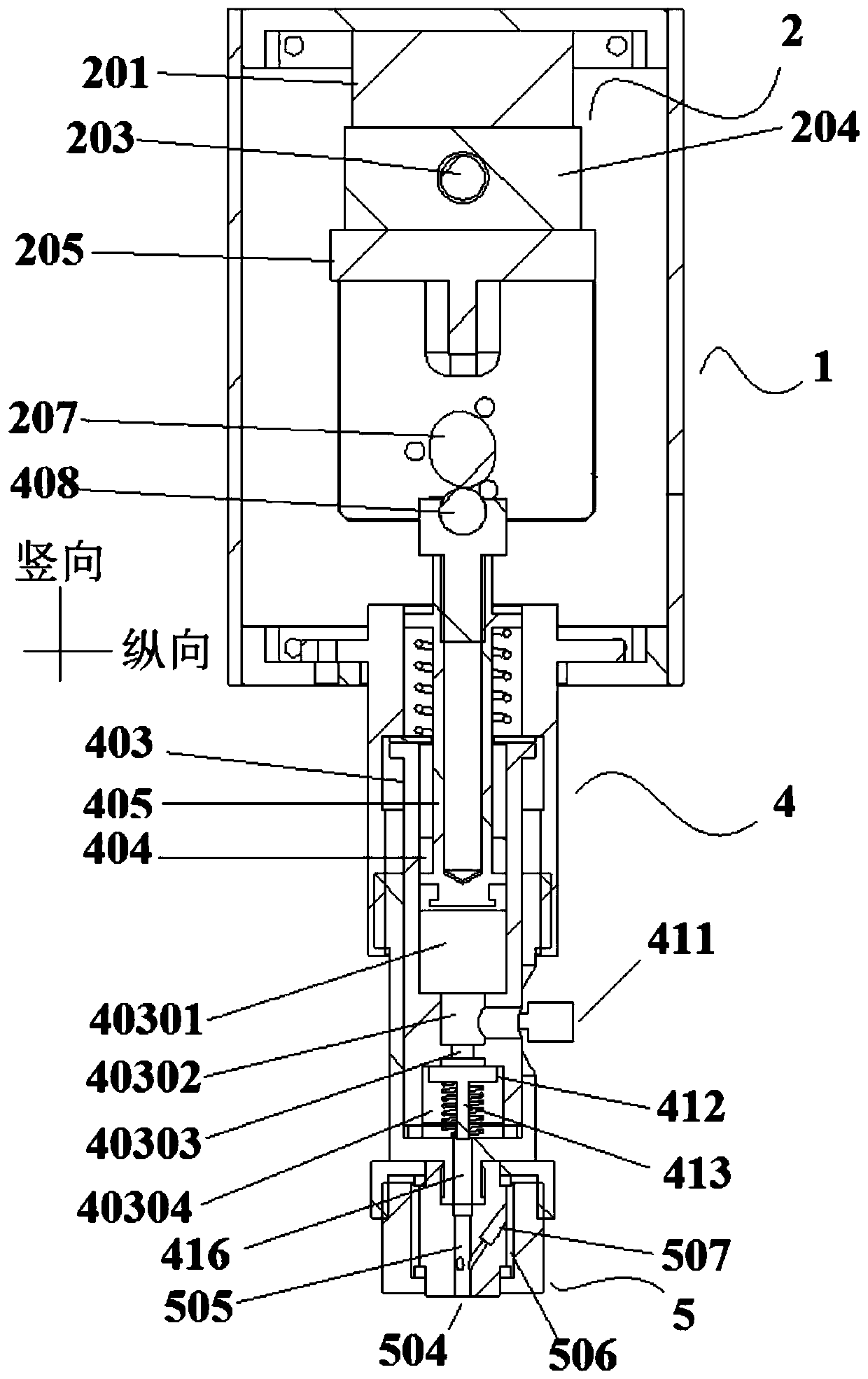

[0055] This embodiment provides a precision nozzle with controllable ejection volume and ejection frequency, such as Figure 1 to Figure 6 As shown, it includes a casing 1, and also includes a luffing mechanism 2, a frequency conversion rotating mechanism 3, a material suction and spray mechanism 4 and an atomization cover 5;

[0056] The luffing mechanism 2 includes a feed seat 201 installed on the inner top surface of the casing 1. A lead screw 203 driven by a feed motor 202 is installed on the feed seat 201. A feed slider 204 is installed on the lead screw 203. The feed slider 204 contacts the feed seat 201 to limit the position, so that the feed slider 204 moves laterally under the drive of the lead screw 203; the bottom of the feed slider 204 is fixedly equipped with a cam mounting seat 205, and A camshaft 206 arranged laterally in a rotatable installation is provided with a cam 207 on the camshaft 206;

[0057] The frequency conversion rotation mechanism 3 is fixedly in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com