Polylactic acid and device and method for preparing polylactic acid

A polylactic acid and driving device technology, applied in chemical instruments and methods, chemical/physical/physical chemical processes, chemical/physical/physical chemical fixed reactors, etc., can solve the problem of high lactide content and long reaction cycle , low conversion rate and other problems, to achieve the effect of reducing lactide monomer content, improving color defects, and high devolatilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0102] This embodiment is to illustrate the polylactic acid prepared by the device and method of the present invention.

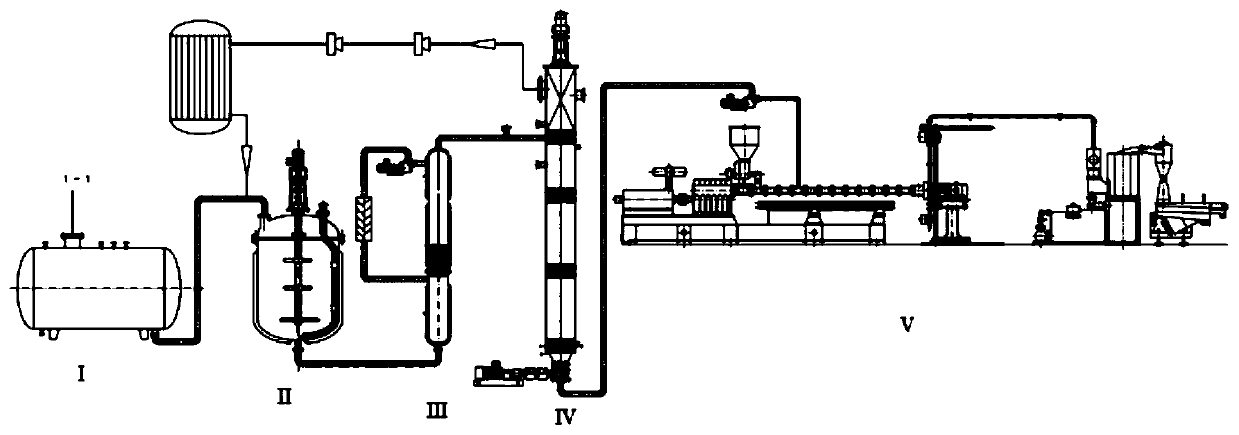

[0103] (1) Lactide melting process: under continuous nitrogen protection, lactide is added to lactide melting tank I, and melted at 95° C. for 1 hour to obtain molten lactide;

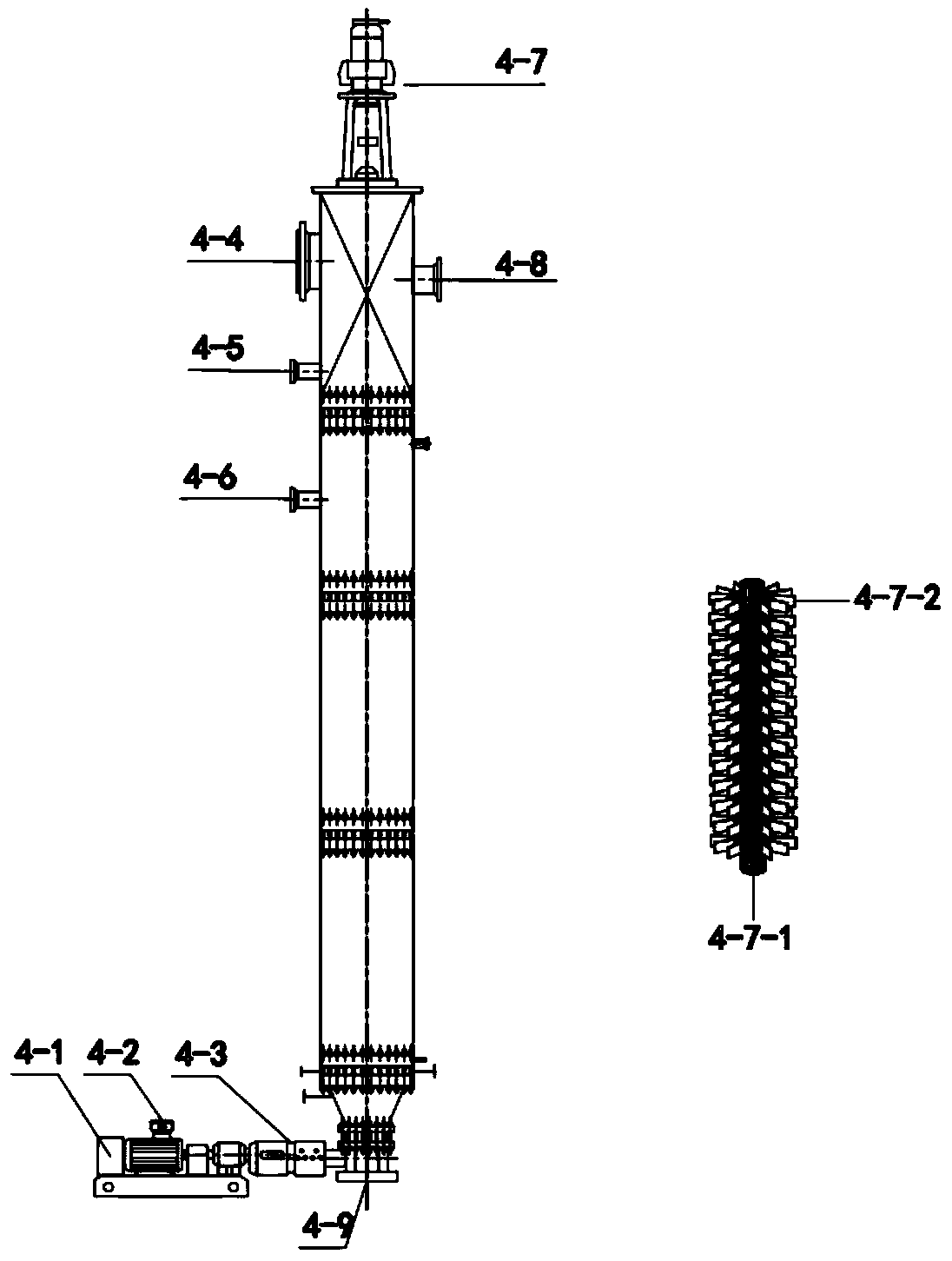

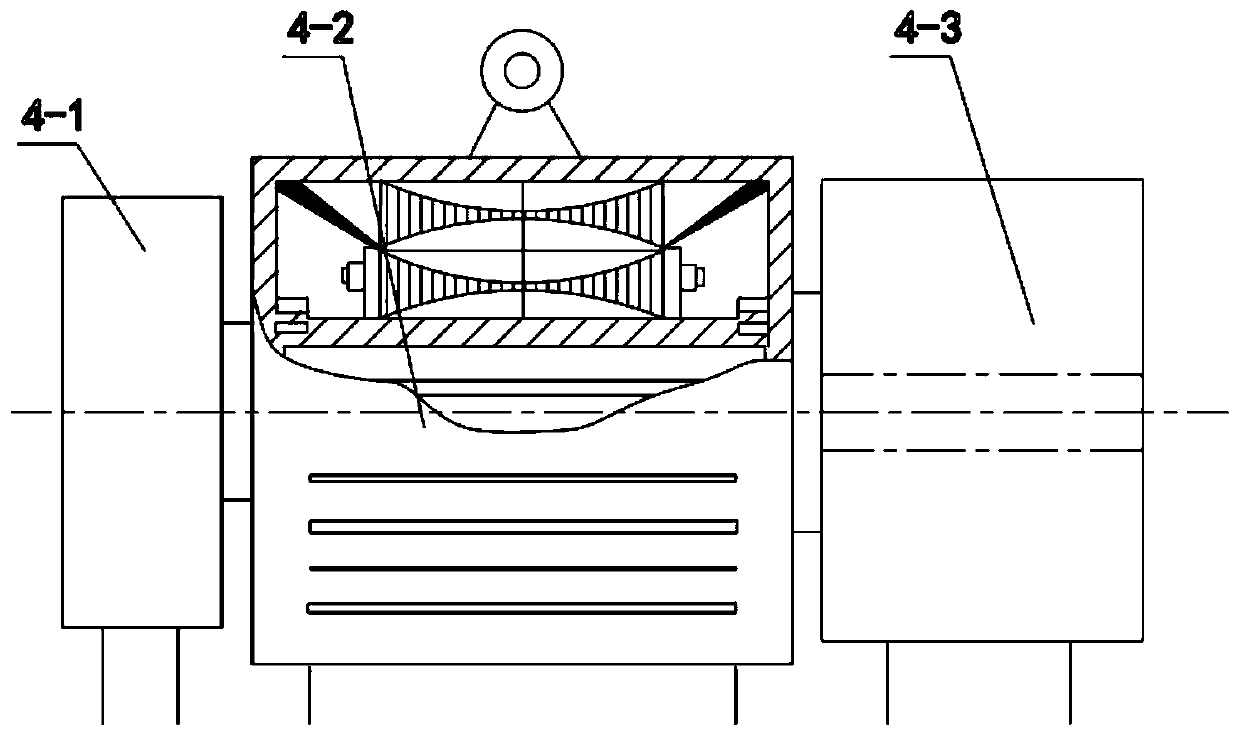

[0104] (2) The first polymerization reaction process: the molten lactide is passed into the first polymerization reactor II, and the catalyst stannous octoate, the ring-opening polymerization initiator polyethylene glycol, and the high-efficiency composite stabilizer CS- 12 (composite stabilizer CS-12 is compounded by AT-76 and AT-626 at a mass ratio of 2:1), the first polymerization reaction is carried out at a temperature of 155°C, a pressure of 50kPa, and a reaction time of 3h , the conversion rate reaches 55%.

[0105] (3) The second polymerization reaction process: the first melt after the first polymerization reaction is passed into the second polymerization reactor III, at a...

Embodiment 2

[0109] This embodiment is to illustrate the polylactic acid prepared by the device and method of the present invention.

[0110] (1) Lactide melting process: under continuous nitrogen protection, lactide is added to lactide melting tank I, and melted at 90° C. for 1 hour to obtain molten lactide;

[0111] (2) The first polymerization reaction process: the molten lactide is passed into the first polymerization reactor II, and the catalyst stannous octoate, the ring-opening polymerization initiator polyethylene glycol, and the high-efficiency composite stabilizer CS- 9 (composite stabilizer CS-9 is compounded by AT-10 and AT-168 at a mass ratio of 2:1), the first polymerization reaction is carried out under the conditions of temperature 150°C, pressure 50kPa, and reaction time 3h , the conversion rate reaches 55%;

[0112] (3) The second polymerization reaction process: the first melt after the first polymerization reaction is passed into the second polymerization reactor III, ...

Embodiment 3-12

[0116] Embodiment 3-12 is to illustrate the polylactic acid prepared by the device and method of the present invention.

[0117] Prepare polylactic acid according to the same device and method as in Example 1, except that the composite stabilizer CS1-12 is replaced, and the conditions in step (d) are modified, and the conditions for preparation are shown in Table 1 , and the test results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com