Elastic upper box efficient anti-sliding flat-die granulator

A granulator and anti-slip technology, which is used in the extrusion and granulation of molds, engine components, mechanical equipment, etc., can solve the problems of loose equipment connection, complicated operation of pressure rollers, and cumbersome installation process, so as to reduce production costs and manufacturing costs. , The effect of reducing manual adjustment operations and reducing production and processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to more fully explain the implementation of the present invention, implementation examples of the present invention are provided. These implementation examples are only illustrations of the present invention, and do not limit the scope of the present invention.

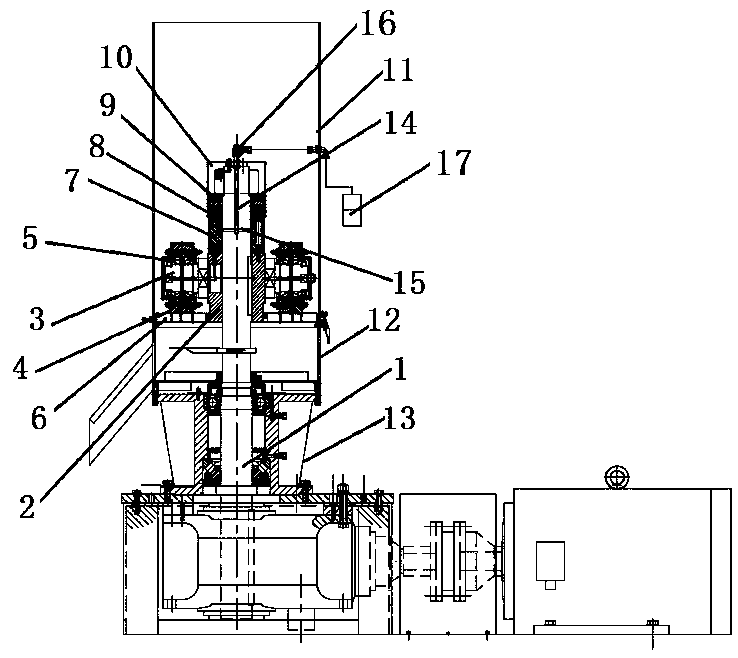

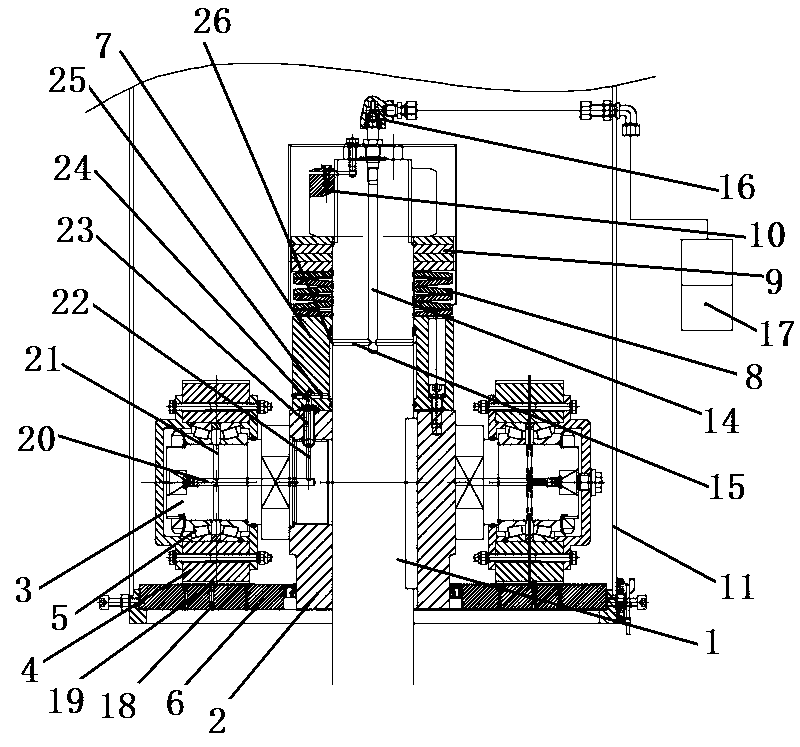

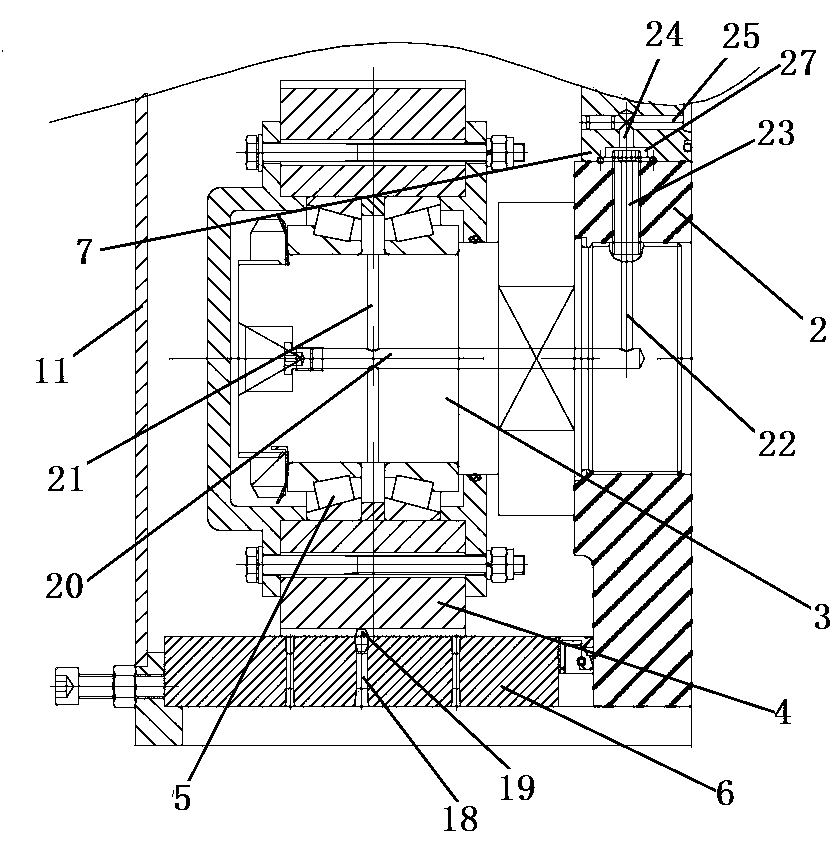

[0021] The present invention is further explained in detail in conjunction with the accompanying drawings. In the accompanying drawings, each mark is: 1: main shaft; 2: pressure roller stand; 3: pressure roller shaft; 4: pressure roller; 5: bearing; Set; 8: disc spring; 9: gasket; 10: nut; 11: upper box; 12: middle box; 13: lower box; 14: axial oil hole C; 15: radial oil hole D ;16: Rotary joint; 17: Oil pump; 18: Type hole; 19: Convex tooth; 20: Axial oil hole A; 21: Radial oil hole A; 22: Radial force oil hole B; 23: Screw; 24 : Axial oil hole B; 25: Radial oil hole C; 27: Annular groove; 28: Groove; 111: Internal resistance fluctuation point 1; 112: Internal resistance fluctuation point 2; 113: Int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com