Favipiravir granular preparation and preparation method therefor

A technology of lavir granules and granule preparations, which is applied in the field of medicine and can solve the problems of difficult swallowing of tablets and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

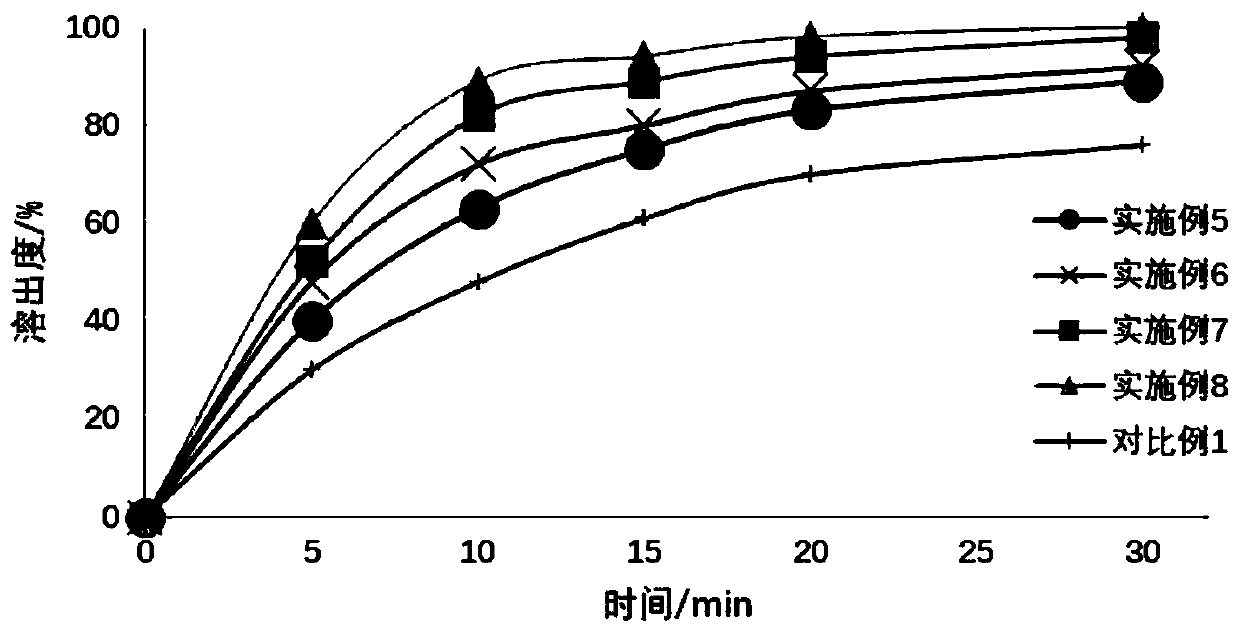

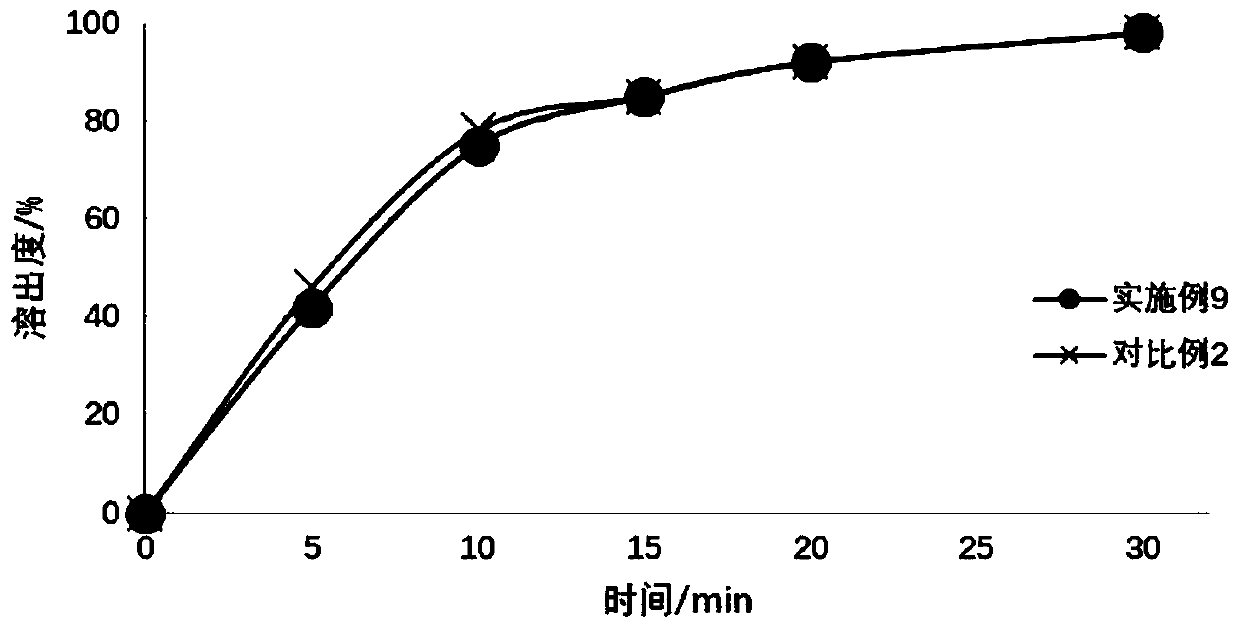

Examples

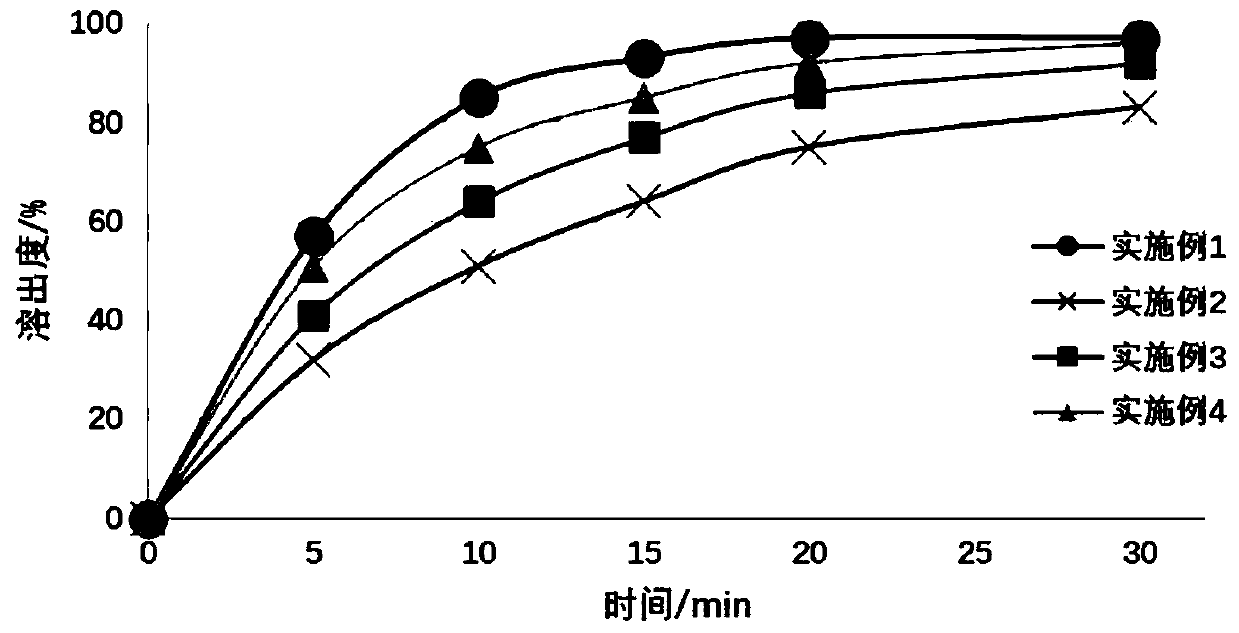

Embodiment 1~4

[0057] The used prescription and prescription consumption of embodiment 1-4 are as shown in table 1 below:

[0058] Table 1

[0059] Component classification name Example 1 Example 2 Example 3 Example 4 parts by weight parts by weight parts by weight parts by weight Main drug Favipiravir 200 200 200 200 filler dextrin 0 200 500 100 suspending agent Tragacanth Gum 10 50 100 150 sweetener sucrose 2000 1300 800 0 sweetener aspartame 0 20 40 80 pH regulator citric acid 1 50 70 120 pH regulator Sodium citrate 10 75 30 20 Glidant Micropowder silica gel 50 50 50 20 Batch / gram 300 300 300 300 Main drug particle size / micron 9.4 38 29 12 Granule formulation pH 5.8 4.9 3.5 2.3 Sedimentation volume ratio 0.91 0.94 0.95 0.96 Taste score 3.1 points 3.7 points 4.3 points 3.5 points

[0060] From the above resu...

Embodiment 1

[0061] Embodiment 1 preparation process steps:

[0062] 1) Favipiravir is subjected to airflow pulverization, the materials are collected, the particle size distribution is measured and controlled, and the D90 is obtained as a bulk drug of 9.4 microns;

[0063] 2) Pass tragacanth gum, sucrose, and micropowdered silica gel through a 60-mesh sieve respectively, and set aside;

[0064] 3) Mix the materials of step 1) and step 2) together in a mixer for 20 minutes to obtain the favipiravir granule formulation.

Embodiment 2~4

[0065] Embodiment 2~4 preparation process steps:

[0066] 1) Favipiravir is subjected to airflow pulverization, the material is collected, and the particle size distribution D90 is measured and controlled to be less than 40 microns;

[0067] 2) Pass the components other than the bulk drug through a 40-mesh sieve respectively, and set aside;

[0068] 3) Mix the other materials except micropowder silica gel and aspartame in step 1) and step 2) in a high-shear granulator, and then add the solution prepared by aspartame and purified water and continue stirring. Get the soft material with suitable wetting degree;

[0069] 4) the soft material of step 3) is carried out wet granulation by using a swing granulator with 40 meshes;

[0070] 5) The material obtained in step 4) is dried, and the obtained dried granules are dry granulated using a 40-mesh screen with an aperture;

[0071] 6) Mix the glidant and the granules obtained in step 5 in a mixer for 10 minutes to obtain the favip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com