Folium mori protein hydrolysate, preparation method thereof and enzyme beverage prepared from folium mori protein hydrolysate

A protein hydrolyzate and enzyme beverage technology, applied in the field of mulberry leaf protein hydrolyzate and its preparation, and enzyme beverage, can solve the problems of long time consumption and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

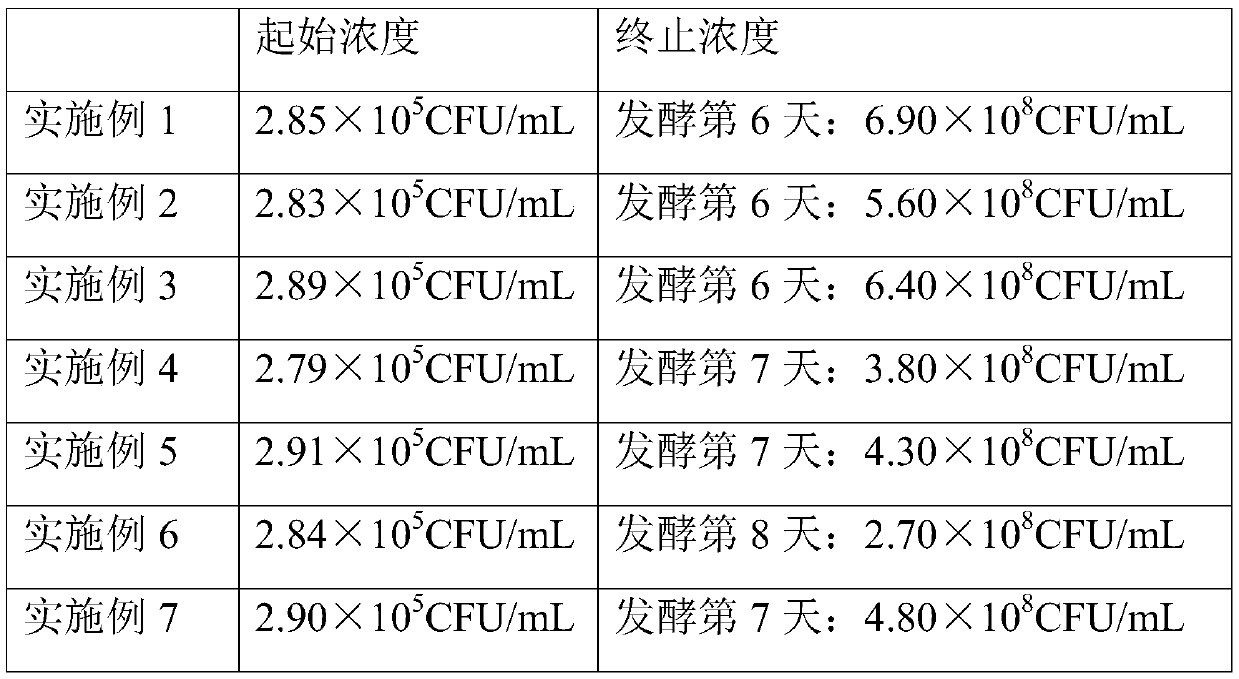

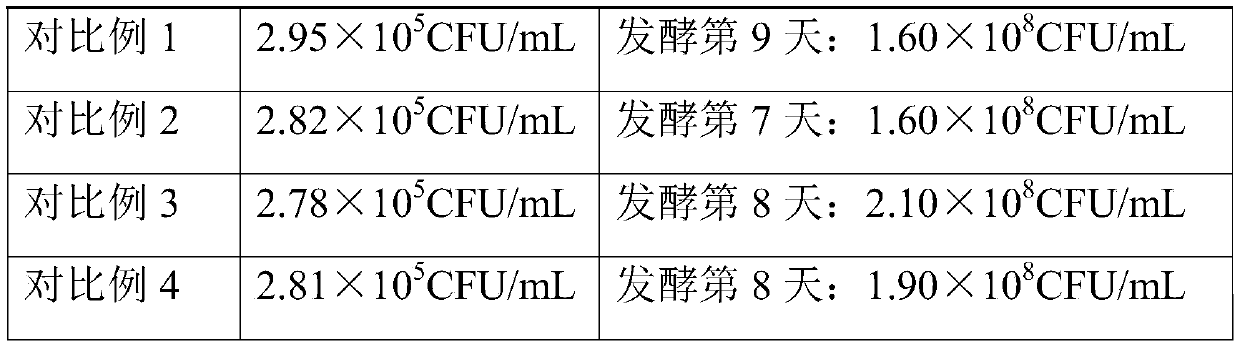

Examples

preparation example Construction

[0024] A preparation method of mulberry leaf protein hydrolyzate, said preparation method comprising:

[0025] The mulberry leaves are prepared into mulberry leaf slurry, and biological enzymes are added to the mulberry leaf slurry for enzymolysis; the biological enzymes include cellulase, pectinase and neutral protease.

[0026] Cellulase can decompose the fiber in mulberry leaf pulp, pectinase can decompose pectin and polysaccharide macromolecular substances, and neutral protease can degrade mulberry leaf macromolecular protein. When the mulberry leaf protein hydrolyzate is used for microbial fermentation, it can shorten the lag phase of fermentation microorganisms and prolong the logarithmic phase of fermentation microorganisms, and can obtain fermentation products with higher active ingredient content in the case of shorter fermentation time.

[0027] The present invention prepares mulberry leaves into mulberry leaf slurry mainly by pulverizing the mulberry leaves as much ...

Embodiment 1

[0056] 1. Preparation of mulberry leaf protein hydrolyzate

[0057] The production process of mulberry leaf protein hydrolyzate: mulberry leaf beating → enzymatic hydrolysis → adding acid to adjust pH → water bath → centrifugation → supernatant is mulberry leaf protein hydrolyzate.

[0058] 1. Mulberry leaf beating: mulberry leaves are beaten with 2 times the quality of water.

[0059] 2. Biological enzymatic hydrolysis: first add 30-200U / mL cellulase to enzymolyze the mulberry leaf beating liquid at 50°C for 20 minutes, then add 50-400U / mL pectinase to enzymolyze the mulberry leaf beating liquid at 40°C for 40 minutes, and finally Add 10-150U / mL neutral protease to enzymolyze the mulberry leaf beating solution at 35°C for 2h.

[0060] 3. Enzyme inactivation: after enzymatic hydrolysis, adjust the pH to 4.0, and keep the temperature at 75°C for 8 minutes.

[0061] 4. Adjust the pH to neutral.

[0062] 5. Centrifuge and take the supernatant.

[0063] 2. Beverage preparation...

Embodiment 2

[0069] 1. Preparation of mulberry leaf protein hydrolyzate

[0070] The production process of mulberry leaf protein hydrolyzate: mulberry leaf beating → enzymatic hydrolysis → adding acid to adjust pH → water bath → centrifugation → supernatant is mulberry leaf protein hydrolyzate.

[0071] 1. Mulberry leaf beating: mulberry leaves are beaten with 2 times the quality of water.

[0072] 2. Biological enzymatic hydrolysis: first add 30-200U / mL cellulase to enzymolyze the mulberry leaf beating liquid at 46°C for 25 minutes, then add 50-400U / mL pectinase to enzymolyze the mulberry leaf beating liquid at 36°C for 45 minutes, and finally Add 10-150U / mL neutral protease to enzymolyze the mulberry leaf beating solution at 32°C for 2.2h.

[0073] 3. Enzyme inactivation: After enzymatic hydrolysis, adjust the pH to 4.0, and keep the temperature at 70°C for 10 minutes.

[0074] 4. Adjust the pH to neutral.

[0075] 5. Centrifuge and take the supernatant.

[0076] 2. Beverage preparat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com