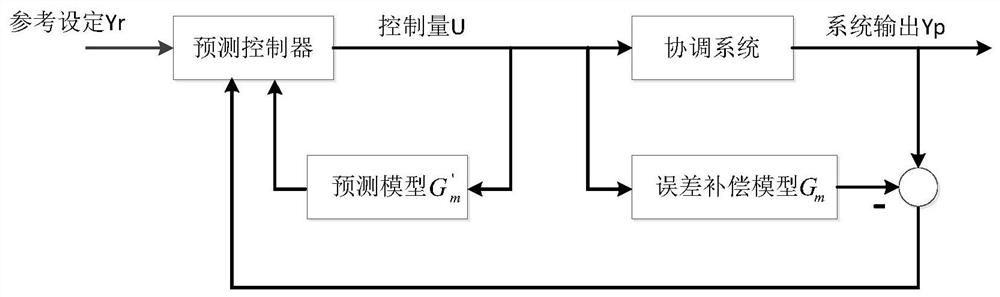

Multi-model predictive control design method for coordinated control system of supercritical thermal power units

A technology for coordinating control systems and thermal power units, applied in general control systems, control/regulation systems, electrical program control, etc., and can solve problems such as heavy computational load, complex controller structure, and difficult engineering applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

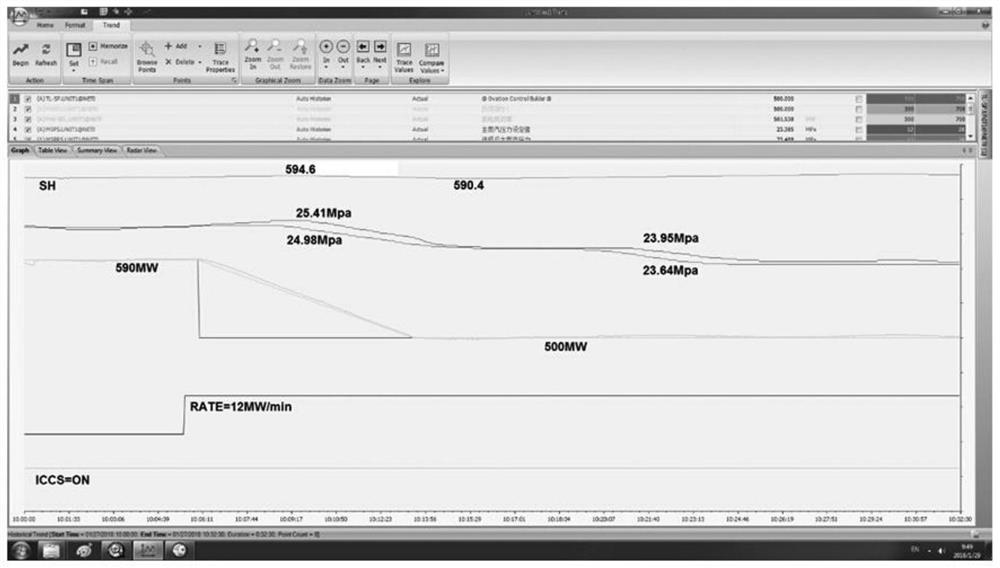

Examples

Embodiment Construction

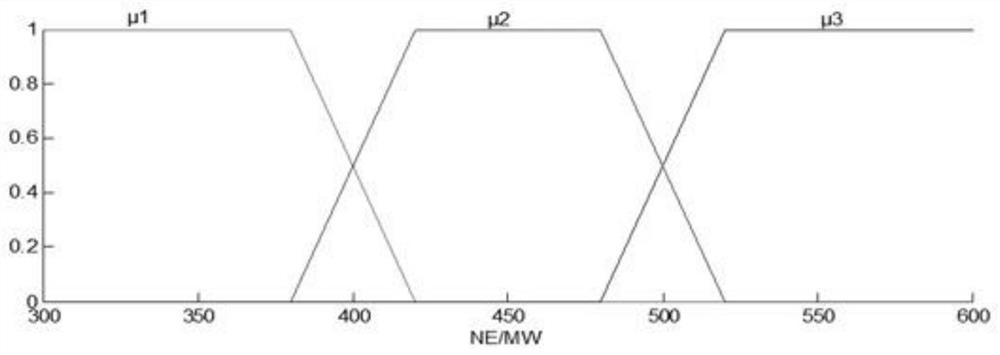

[0083] Considering that the dynamic characteristic relationship between each sub-circuit in the coordination system is a self-balancing process but there are some inverse response characteristics, a perfect second-order model is used to simplify the controlled process, the model has zero points, and the coordination object of the supercritical thermal power unit A 3×3 multi-input and multi-output object can be used, and the range of local load point cells can be represented by the model shown in formula (1):

[0084]

[0085] In formula (1), k ij (i, j=1, 2, 3) is the gain coefficient, T ij (i,j=1,2,3), T abc (a, b=1,2,3; c=1,2) is the time constant, τ ij (i, j=1, 2, 3) is the delay time, and S is the Laplacian operator. Based on formula (1), the estimated prediction of the coordinated system output can use the following expression:

[0086]

[0087] In formula (2), y 1 (s), y 2 (s), y 3 (s) is the system output, u 1 (s), u 2 (s), u 3 (s) is the system input. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com