A kind of mofs-based gel electrolyte and its preparation and application

A technology of gel electrolyte and electrolyte, which is applied in instruments, nonlinear optics, optics, etc., can solve the problems of poor ion conductivity and mechanical properties, and achieve excellent discoloration performance, excellent mechanical properties, and stable work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] (1) After dissolving 57.42g LiTFSI in 100mL PC, a 2mol / L LiTFSI / PC solution was obtained, and then 60mL of this solution was blended with 10mL [Emim][TFSI] to obtain a transparent electrolyte;

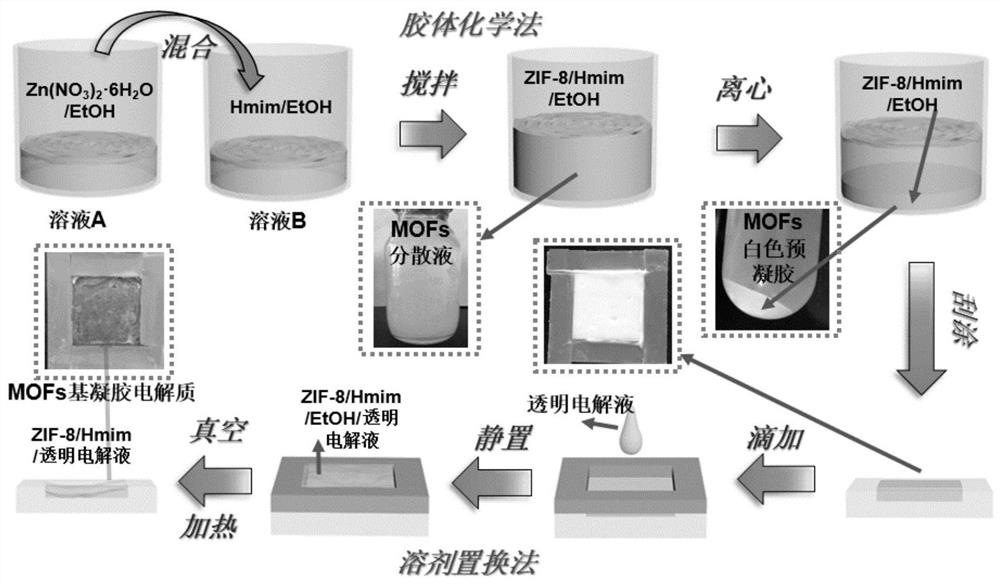

[0042] (2) 4.36g Zn(NO 3 ) 2 ·6H 2 0, 6.16g Hmim were dissolved in 300mL EtOH (molar ratio 1:5:700), respectively, to prepare solution A and solution B. After that, solution A was quickly poured into solution B, and after 45 minutes of magnetic stirring, the MOFs dispersion was obtained, and then centrifuged at 5000rpm / min for 12 minutes, and the supernatant was poured off to obtain the MOFs white pre-gel;

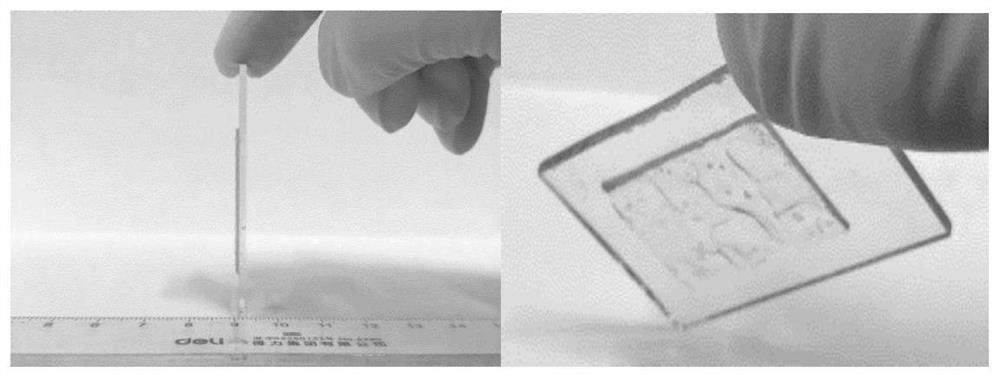

[0043] (3) Spread the MOFs pre-gel obtained in step (2) on a surface with a volume of 1.0 cm 3 In the groove, add 1.0mL transparent electrolyte obtained in step (1) dropwise on the surface of MOFs pre-gel, let it stand for 1h, and heat it at 80℃ for 14h with a vacuum degree of -0.10MPa to obtain the MOFs-based gel electrolyte .

[0044] The preparation process of the MO...

Embodiment 2

[0049] (1) 1.52g LiPF 6 After dissolving in 100mL EC, 0.1mol / L LiPF was obtained 6 / EC solution, after which 30mL of this solution was mixed with 10mL [Emim][BF 4 ] blending to obtain a transparent electrolyte;

[0050] (2) 5.82g Zn(NO 3 ) 2 ·6H 2 0 and 4.82g Hmim were dissolved in 400mL EtOH (three molar ratios were 1:3:700), respectively, to prepare solution A and solution B. After that, solution A was quickly poured into solution B, and after 90 minutes of magnetic stirring, the MOFs dispersion was obtained, and then centrifuged at 12,000 rpm / min for 4 minutes, and the supernatant was poured off to obtain the MOFs white pre-gel;

[0051] (3) Spread the MOFs pre-gel obtained in step (2) on a surface with a volume of 2.0 cm 3 Add 8.0mL of transparent electrolyte obtained in step (1) dropwise to the surface of MOFs pre-gel, let it stand for 3 hours, and heat at 90℃ for 8 hours with a vacuum degree of –0.06MPa to obtain the MOFs-based gel electrolyte. .

[0052] The app...

Embodiment 3

[0055] (1) 10.64g LiClO 4 After dissolving in 100mL PC, 1mol / L LiClO was obtained 4 / PC solution, then mix 50 mL of this solution with 5 mL of [Emim][BF 4 ] blending to obtain a transparent electrolyte;

[0056] (2) 2.911g Zn(NO 3 ) 2 ·6H 2 0, 6.427g Hmim were dissolved in 200mL EtOH (three molar ratios were 1:8:700), respectively, to prepare solution A and solution B. After that, solution A was quickly poured into solution B, and after magnetic stirring for 60 minutes, the MOFs dispersion was obtained, and then centrifuged at 8000rpm / min for 8 minutes, and the supernatant was poured off to obtain the MOFs white pre-gel;

[0057] (3) Spread the MOFs pre-gel obtained in step (2) on a surface with a volume of 2.0 cm 3 Add 4.0mL of the transparent electrolyte obtained in step (1) dropwise to the surface of the MOFs pre-gel, let it stand for 2 hours, and heat at 80°C for 12 hours with a vacuum of –0.08MPa to obtain the MOFs-based gel electrolyte. .

[0058] There is no big...

PUM

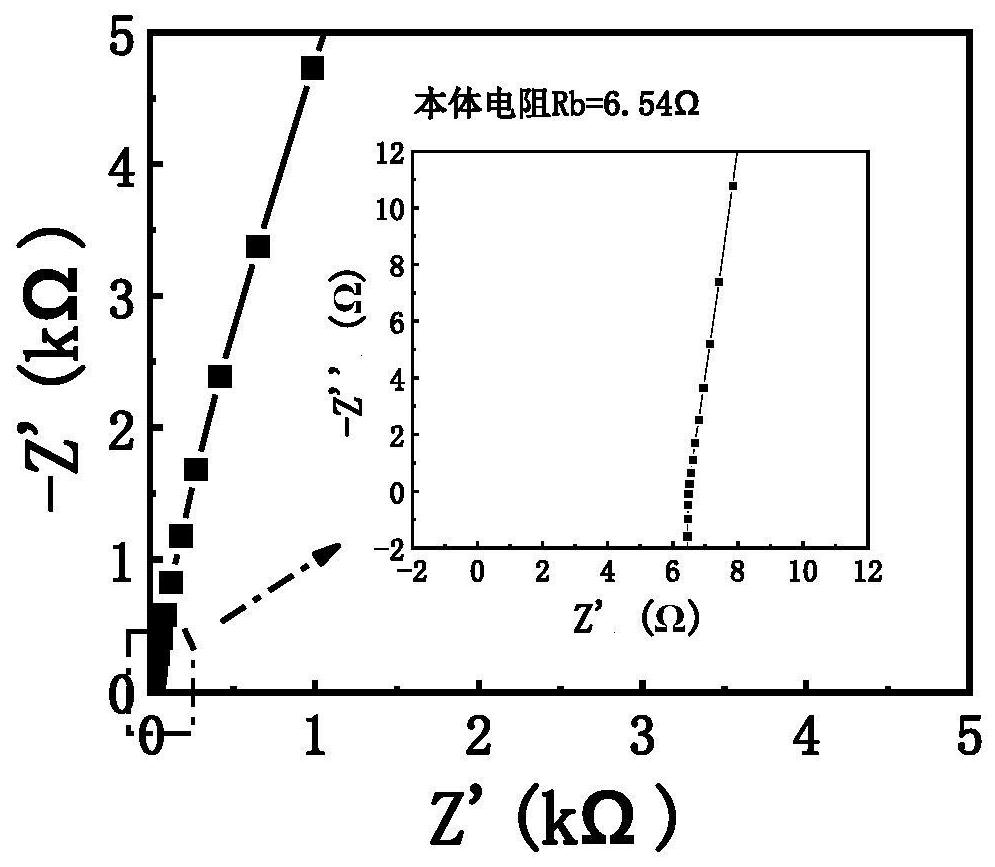

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com