Compaction pile construction device and method thereof

A construction device and compaction pile technology, which is applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of high noise affecting the environment, low processing efficiency, time-consuming and labor-intensive, etc., to shorten the release time, reduce maintenance costs, noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

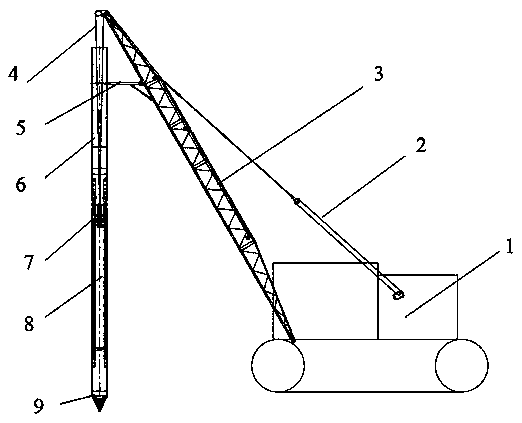

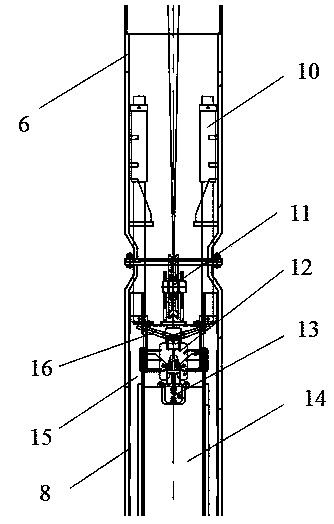

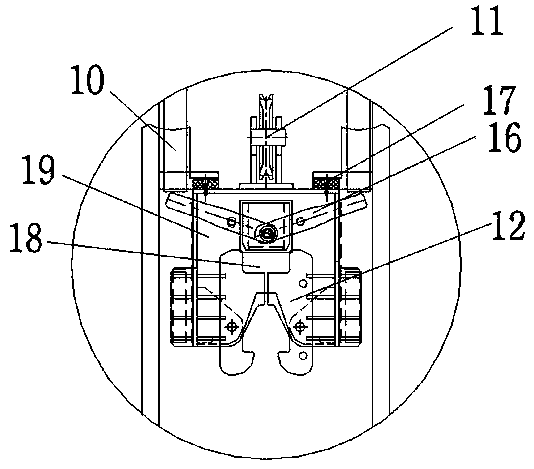

[0036]As shown in the drawings: a construction device for compaction piles, including a host platform 1, a tower frame 3 and pile pipes 25, the tower frame 3 is set on the host platform 1, and the upper end of the tower frame 3 is connected to the host platform 1 through a tie rod 2 , the host platform 1 and the tower frame 3 are used to control and adjust the position and work of the pile tube 25, the pile tube 25 is detachably connected with the tower frame 3 through a support device, and the pile tube 25 is provided with a hammer body 14, a decoupling device 7 and a guide rail 15 , the guide rail 15 is vertically installed on the inner wall of the pile pipe 25, and the hammer body 14 is controlled by the uncoupling device 7 along the guide rail 15 in the pile pipe 25 to freely fall and hit the bottom of the pile pipe 25 to sink together. Preferably, the upper end of the hammer body 14 is provided with a Hanging head 13, the upper end of the hanging head 13 is conical, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com