A repair method for unlocking of dense sand layer steel sheet piles

A repair method and technology for steel sheet piles, which are applied in sheet pile walls, buildings, infrastructure engineering, etc., and can solve problems such as difficulty in guaranteeing weld quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

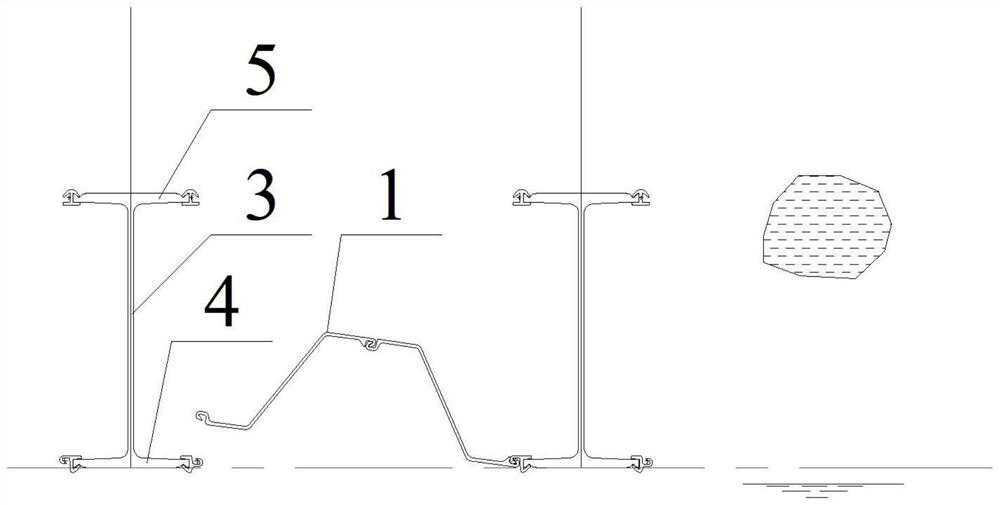

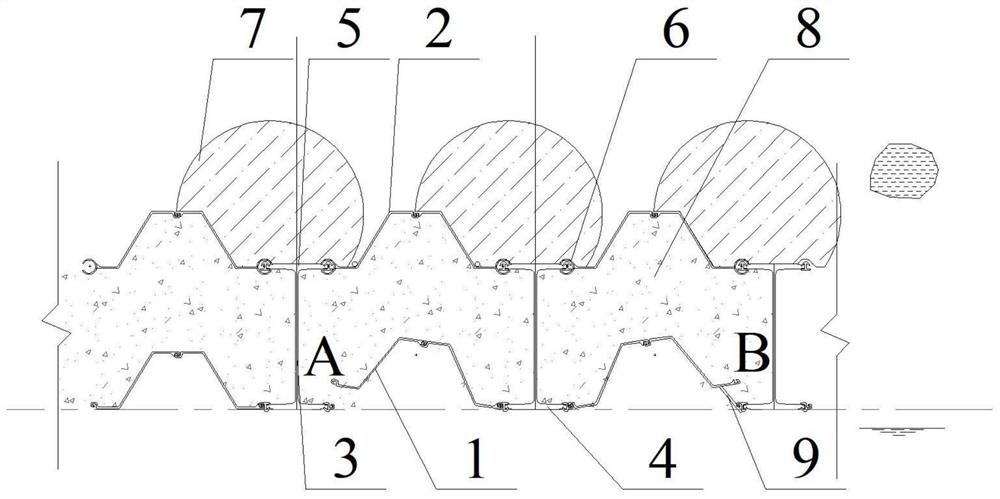

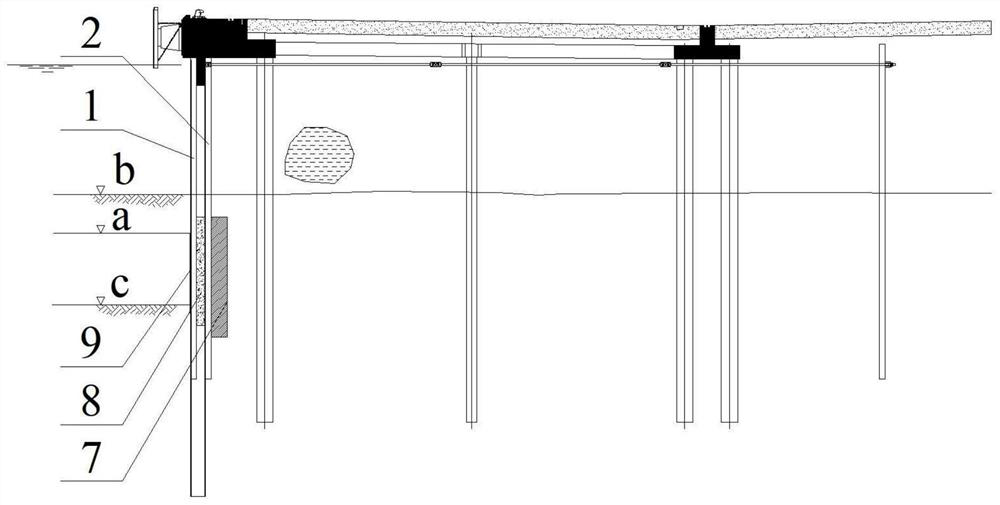

[0026] Such as figure 1 As shown, during the dredging process, the first steel sheet pile 1 of this embodiment was found to be out of lock with the I-shaped steel sheet pile 3, that is, the first steel sheet pile 1 and the first flange 4 of the I-shaped steel sheet pile 3 There is a phenomenon that the lock is disengaged at the end, such as figure 2 As shown at A and B, the elevation a of the unlocking place is below the original mud surface b (such as image 3 As shown), the harbor basin needs to be dredged to the design mud surface c. During the dredging process, the out-of-lock position is exposed. If the out-of-lock position is not repaired, the sand backfilled on the side of the first steel sheet pile 1 away from the harbor basin will pass through the out-of-lock It flowed into the harbor basin, causing the front edge of the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com