Preparation method of terbutaline derivatives

A technology for terbutaline derivatives, applied in the field of preparation of terbutaline derivatives, to achieve the effects of high product purity, good environmental protection effect, and reasonable process design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

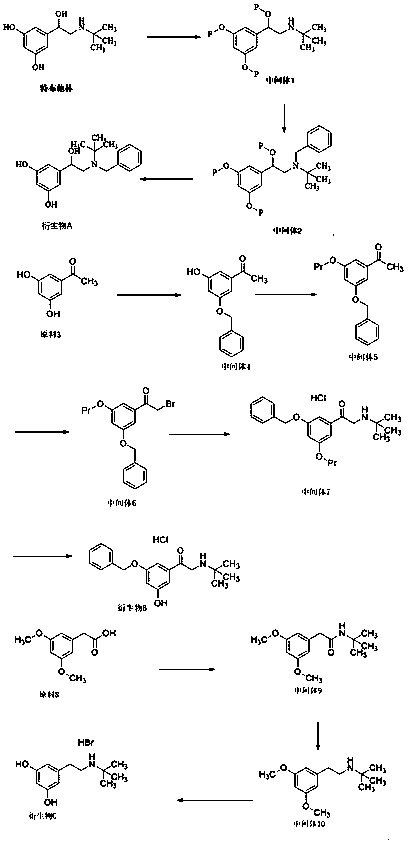

[0037] Such as figure 1 Shown, the preparation method of terbutaline derivative A comprises the following steps:

[0038] (1) Dissolve 20 g of terbutaline in 200 ml of acetonitrile, add 30 g of pyridine and 54 g of tert-butyldimethylchlorosilane to react at room temperature for two hours, concentrate, dilute with dichloromethane, wash with water, and concentrate to obtain 40 g of intermediate 1 , yield 85%;

[0039] (2) Dissolve 20g of intermediate 1 in dimethyl sulfoxide, add 10g of sodium bicarbonate and 9g of benzyl chloride, react at 40°C for 3 hours, add 300ml of water to dilute, extract with ethyl acetate, concentrate, and purify by column chromatography After obtaining about 14g of intermediate 2, the yield is 65%;

[0040] (3) Dissolve 7g of intermediate 2 in 70ml of tetrahydrofuran, add 20ml of dilute hydrochloric acid with a concentration of 4mol / L to reflux for 4 hours, adjust the pH to 7-8 with sodium hydroxide, extract with dichloromethane, and then purify by co...

Embodiment 2

[0042] Such as figure 1 Shown, the preparation method of terbutaline derivative A comprises the following steps:

[0043] (1) Dissolve 20 g of terbutaline in 200 ml of dimethyl sulfoxide, add 30 g of pyridine and 54 g of tert-butyldimethylchlorosilane to react at room temperature for two hours, concentrate, dilute with dichloromethane, wash with water, and concentrate to obtain 38g intermediate 1, yield 81%;

[0044] (2) Dissolve 20g of intermediate 1 in dimethyl sulfoxide, add 10g of sodium bicarbonate and 9g of benzyl chloride, react at 60°C for 2 hours, add 300ml of water to dilute, extract with ethyl acetate, concentrate, and purify by column chromatography After obtaining about 15g of intermediate 2, the yield is 61%;

[0045](3) Dissolve 14g of intermediate 2 in 150ml of tetrahydrofuran, add 40ml of dilute hydrochloric acid with a concentration of 4mol / L to reflux for 4 hours, adjust the pH to 7-8 with sodium hydroxide, extract with dichloromethane, and then purify by ...

Embodiment 3

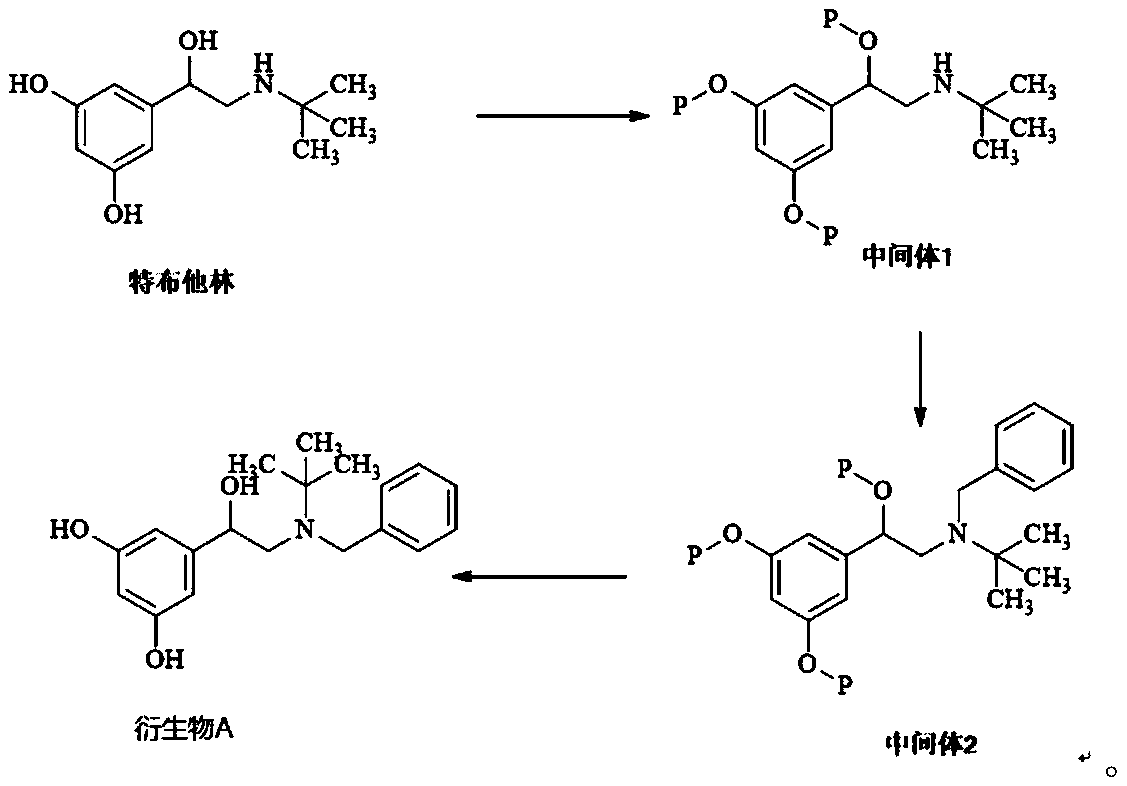

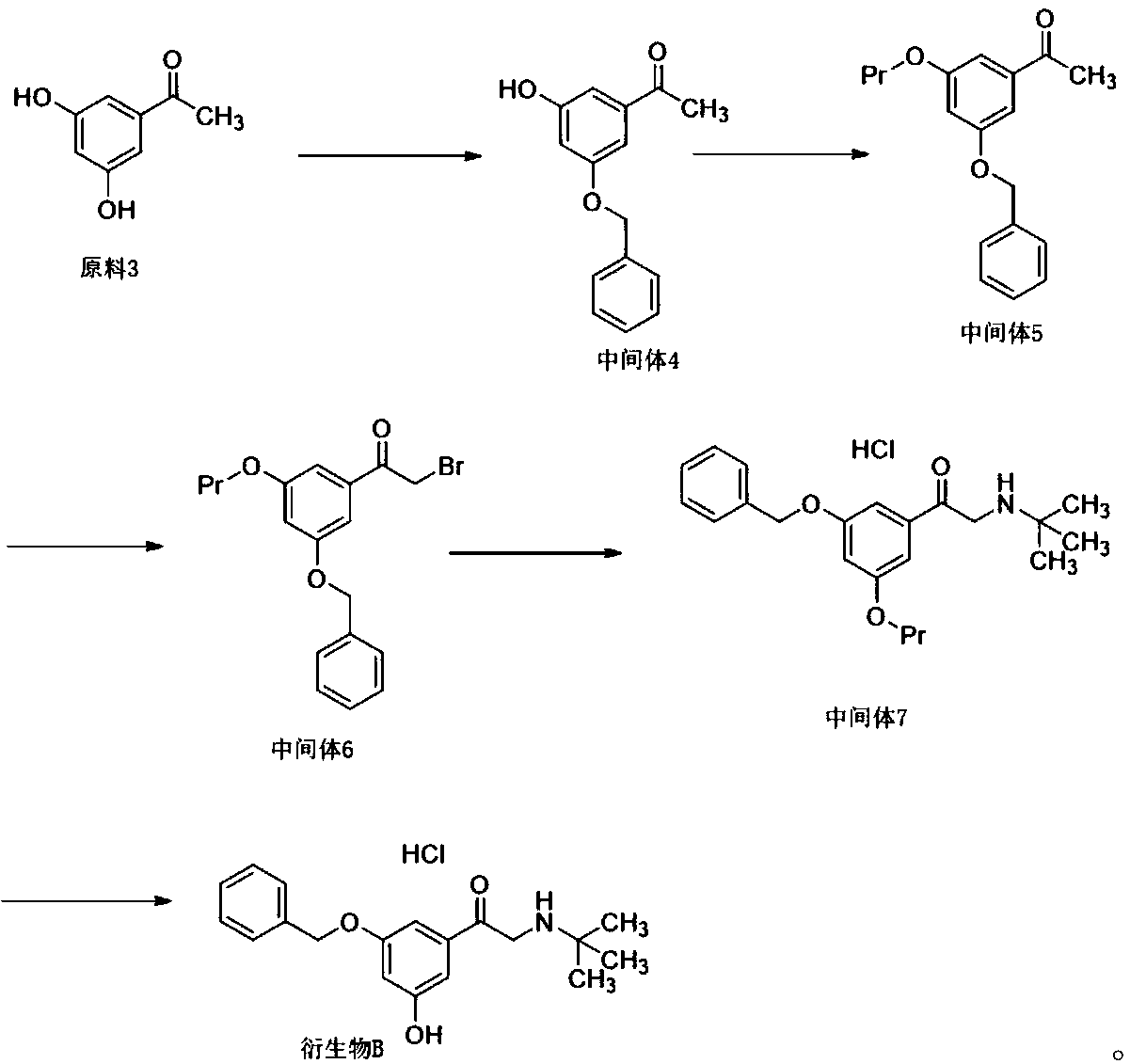

[0047] Such as figure 1 Shown, the preparation method of terbutaline derivative B comprises the following steps:

[0048] (1) Dissolve 60g of raw material 3 in 500ml of acetonitrile, add 100g of potassium carbonate and 67g of benzyl bromide to react at 40°C for 3 hours, add 600ml of water to dilute, extract with ethyl acetate, concentrate, and obtain about 80g of intermediate after purification by column chromatography 4. The yield is 84%;

[0049] (2) Dissolve 55g of intermediate 4 in 550ml of acetonitrile, add 51g of pyridine and 51g of tert-butyldimethylchlorosilane to react at room temperature for two hours, concentrate, dilute with dichloromethane, wash with water and concentrate to obtain 70g of intermediate 5, Yield 86%;

[0050] (3) Dissolve 70g of intermediate 5 in 700ml of acetonitrile, add 100g of N-bromosuccinimide, react at 60°C for 4 hours, concentrate and purify by column chromatography to obtain 70g of intermediate 6, with a yield of 82%;

[0051] (4) 25g of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com