Suction barrel device for sucking, grabbing and stacking food without turning over food

A food and suction cup technology, applied in the field of food processing and packaging equipment, can solve the problems of high production cost and maintenance cost, complex processing process, and impact on production efficiency, and achieve reduced installation and maintenance costs, high power transmission efficiency, and high action efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

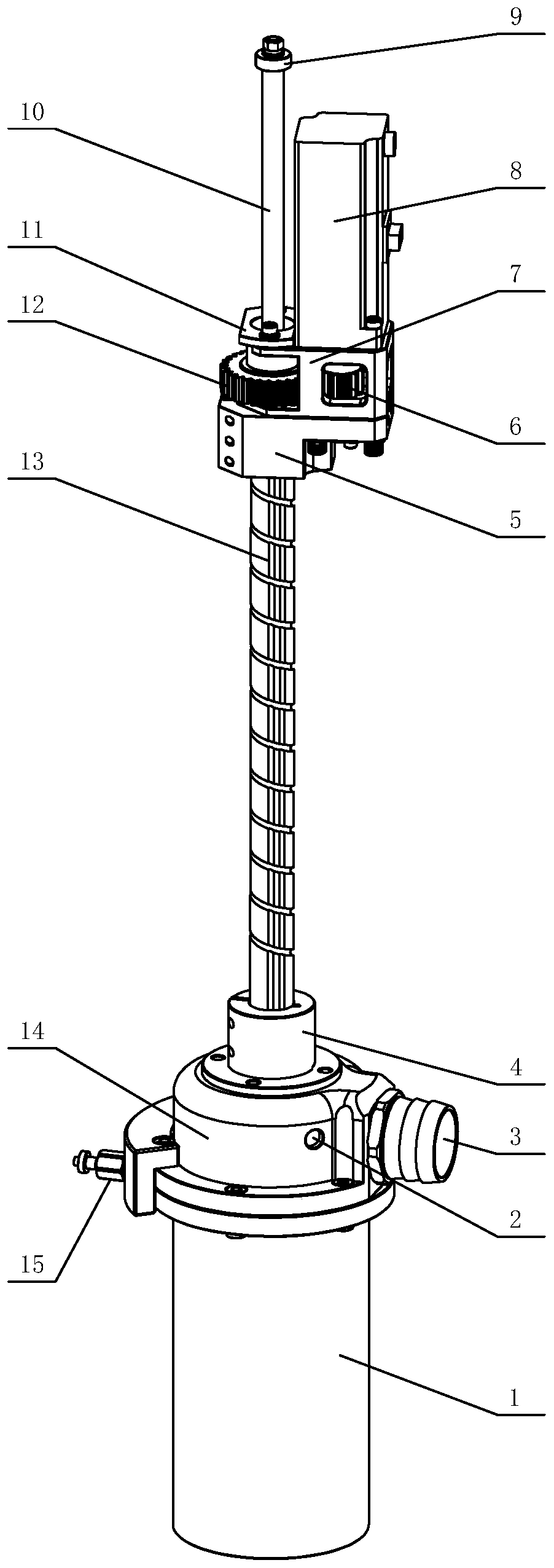

[0031] Such as Figure 1-5 As shown, a suction bucket device for absorbing, grasping and stacking food with anti-turnover, the device includes a Z-axis screw 13, a suction bucket assembly, and a suction cup lifting drive mechanism that drives the suction cup 18 to lift up and down in the suction bucket 1, the described The suction bucket 1 assembly includes the suction bucket fixing seat 14 and the suction bucket 1, and the suction bucket 1 is provided with a suction cup 18, and the suction bucket assembly is located below the Z-axis screw 13, and the Z-axis screw 13 is a hollow structure The lifting drive mechanism of the suction cup 18 is connected with the suction cup 18 through the internal hollow cavity of the Z-axis screw 13, and drives the suction cup 18 to lift in the suction bucket 1. The lifting and lowering driving mechanism of the suction cup 18 is mechanical.

[0032] In this embodiment, the suction cup lifting drive mechanism includes a push rod device, a push ro...

Embodiment 2

[0048] The difference between this embodiment and embodiment 1 is:

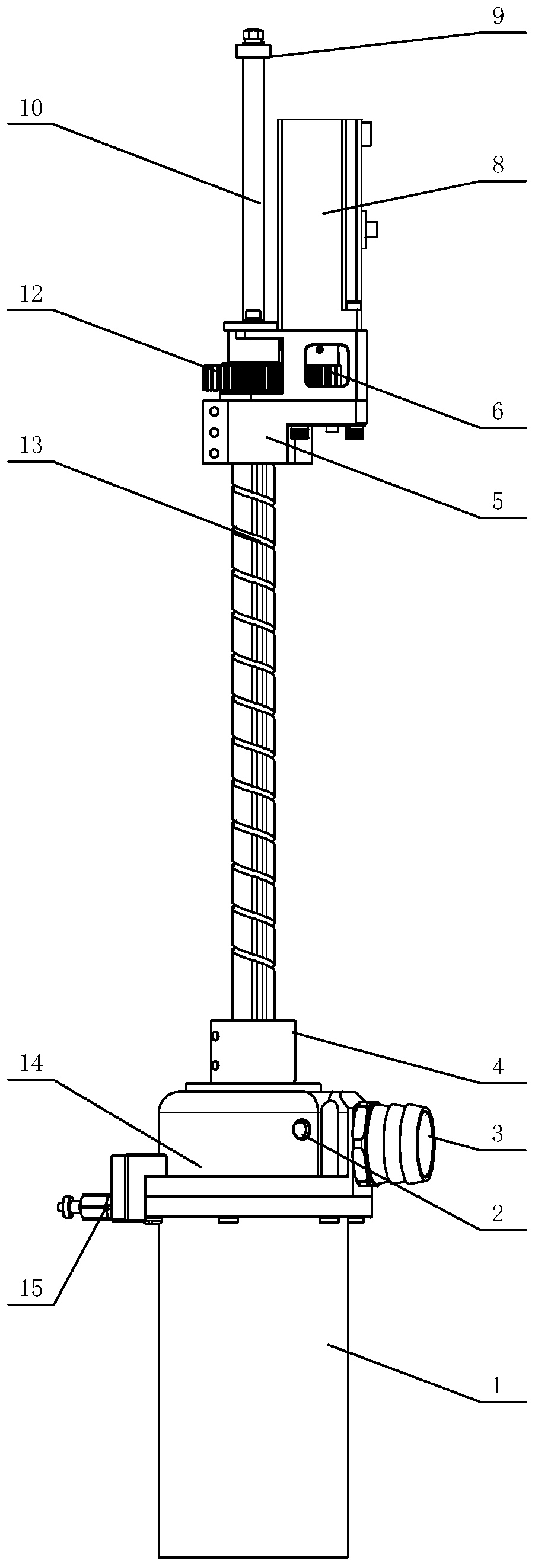

[0049] Such as Image 6 As shown, in this embodiment, the transmission mechanism is a rack-and-pinion type, including the driving gear 6, the push rod is a rack-type push rod 20, and the upper end of the Z-axis screw 13 is provided with a push rod. The rod motor fixing seat 5, the drive gear 6 is fixedly connected with the output end of the push rod driving motor 8, and the drive gear 6 and the rack type push rod 20 are meshed with each other. The driving gear 6 is driven to rotate by the push rod driving motor 8, and is transmitted to the rack type push rod 20 by the driving gear 6. When the internally threaded gear 12 rotates, the rack type push rod 20 can be driven on the hollow Z-axis screw 13 to move up and down, thereby driving the suction cup 18 to move up and down in the suction bucket 1.

[0050] In this embodiment, the push rod motor fixing seat 5 is provided with a rack guide seat 26 , and the ra...

Embodiment 3

[0054] Such as Figure 10-12 As shown, a suction bucket device for absorbing, grasping and stacking food with anti-turnover, the device includes a Z-axis screw 13, a suction bucket assembly, and a suction cup lifting drive mechanism that drives the suction cup 18 to lift up and down in the suction bucket 1, the described The suction bucket assembly includes a suction bucket fixing seat 14 and a suction bucket 1. The suction bucket assembly is provided with a suction cup 18. The suction bucket assembly is located below the Z-axis screw 13, and the Z-axis screw 13 is Hollow structure, the suction cup lifting drive mechanism is connected with the suction cup 18 through the inner hollow cavity of the hollow Z-axis screw 13, and drives the suction cup 18 to rise and fall in the suction bucket 1, and the suction cup lifting drive mechanism is pneumatic Mode.

[0055] In the present embodiment, the suction cup lifting drive mechanism includes a push rod 32, a lifting cylinder 27, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com