Automatic rust removing method for large splicing seam of ship hull plate

A technology of hull outer plate and splicing seam, which is applied in the field of ship painting and manufacturing to achieve the effects of improving rust removal efficiency, reducing labor cost and improving rust removal effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

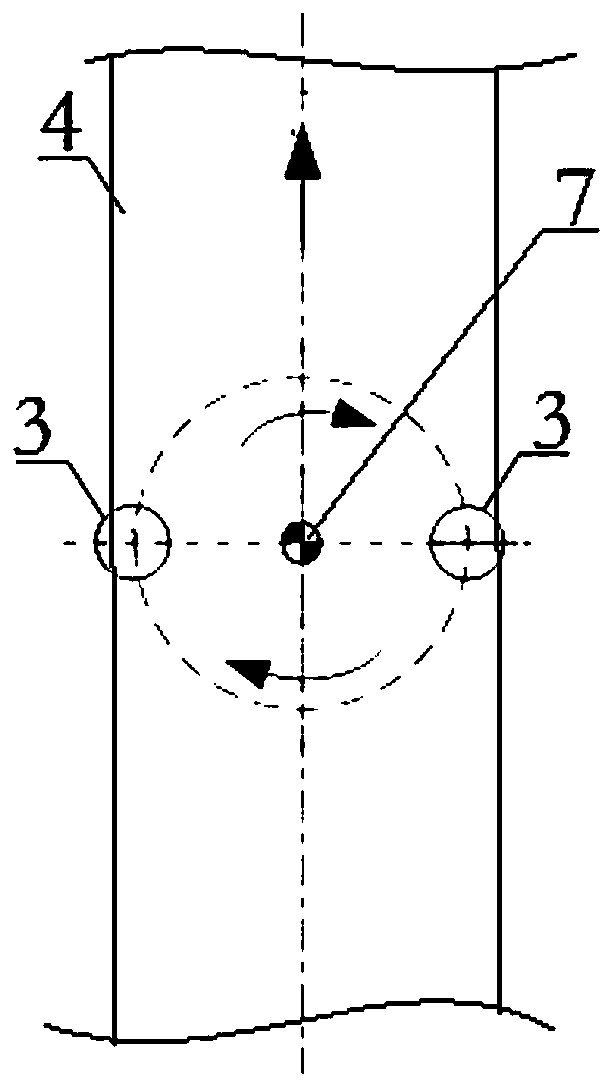

[0039] Such as figure 2 As shown, the present embodiment provides a method for automatic derusting of large joints of hull panels, comprising the following steps:

[0040] Step 1. Measure the shape, length and width of the weld seam to be sandblasted. In this embodiment, one seam 4 is set, the width of the seam 4 is 300mm, and the length of the seam 4 is 30m.

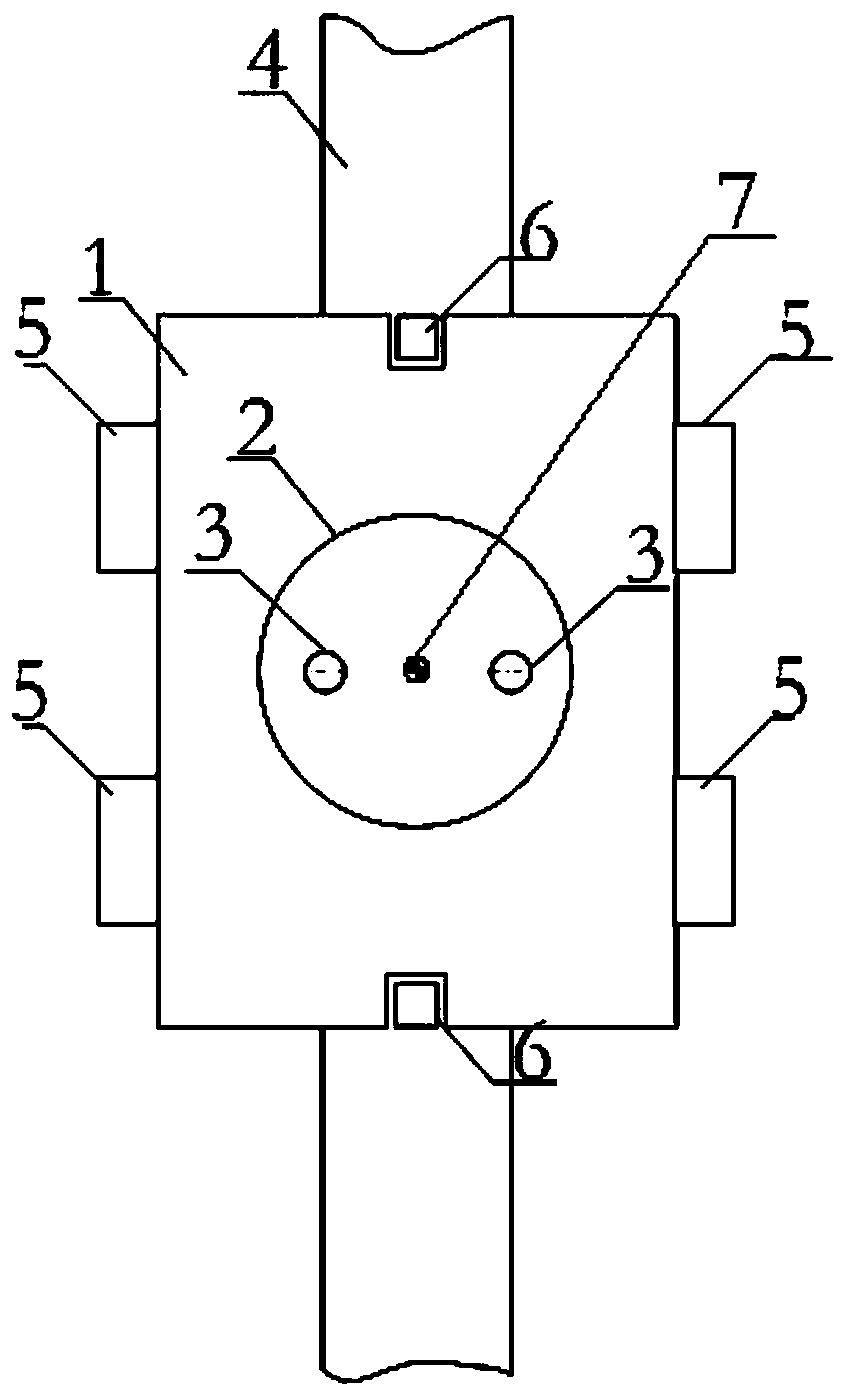

[0041] Step 2. Install the wall-climbing robot 1 and the sandblasting gun 3. The sandblasting gun 3 is installed on the edge of the rotating disk 2. There are two symmetrically arranged sandblasting guns 3. The middle part of the rotating disk 2 is connected to the wall-climbing robot 1 axis. , connect the sand inlet pipe joint of the sandblasting gun 3 to the sand conveying system, the sandblasting diameter of the sandblasting gun 3 is 30-80mm, and the distance between the nozzle of the sandblasting gun 3 and the center of the rotating disk 2 is 150mm. The rotating disk 2 is driven by a rotating motor, and the rotati...

Embodiment 2

[0046] Such as image 3 As shown, the present embodiment provides a method for automatic derusting of large joints of hull panels, comprising the following steps:

[0047] Step 1. Measure the shape, length and width of the weld seam to be sandblasted. In this embodiment, one seam 4 is set, the width of the seam 4 is 180mm, and the length of the seam 4 is 30m.

[0048] Step 2. Install the wall-climbing robot 1 and the sandblasting gun 3. The sandblasting gun 3 is installed on the edge of the rotating disk 2. There are two symmetrically arranged sandblasting guns 3. The middle part of the rotating disk 2 is connected to the wall-climbing robot 1 axis. , connect the sand inlet pipe joint of the sandblasting gun 3 to the sand conveying system, the sandblasting diameter of the sandblasting gun 3 is 30-80mm, and the distance between the nozzle of the sandblasting gun 3 and the center of the rotating disk 2 is 150mm. The rotating disk 2 is driven by a rotating motor, and the rotatin...

Embodiment 3

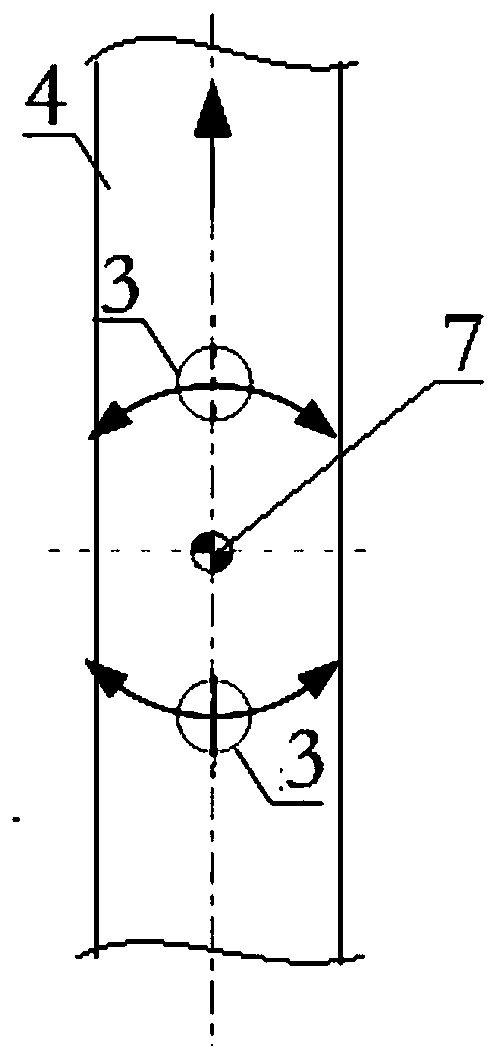

[0053] Such as Figure 4 As shown, the present embodiment provides a method for automatic derusting of large joints of hull panels, comprising the following steps:

[0054] Step 1. Measure the shape, length and width of the weld seam to be sandblasted. In this embodiment, two seams 4 are set, the width of the seam 4 is 60mm, and the length of the seam 4 is 30m.

[0055] Step 2. Install the wall-climbing robot 1 and the sandblasting gun 3. The sandblasting gun 3 is installed on the edge of the rotating disk 2. There are two symmetrically arranged sandblasting guns 3. The middle part of the rotating disk 2 is connected to the wall-climbing robot 1 axis. , connect the sand inlet pipe joint of the sandblasting gun 3 to the sand conveying system, the sandblasting diameter of the sandblasting gun 3 is 30-80mm, and the distance between the nozzle of the sandblasting gun 3 and the center of the rotating disk 2 is 150mm. The rotating disk 2 is driven by a rotating motor, and the rotat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com