Desktop support capable of being assembled quickly

A desktop bracket and fast technology, applied in the field of intelligent lifting table, can solve the problems of cumbersome installation method, reduce production efficiency, increase production cost, etc., and achieve the effect of eliminating welding process, high production efficiency, and reliable use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

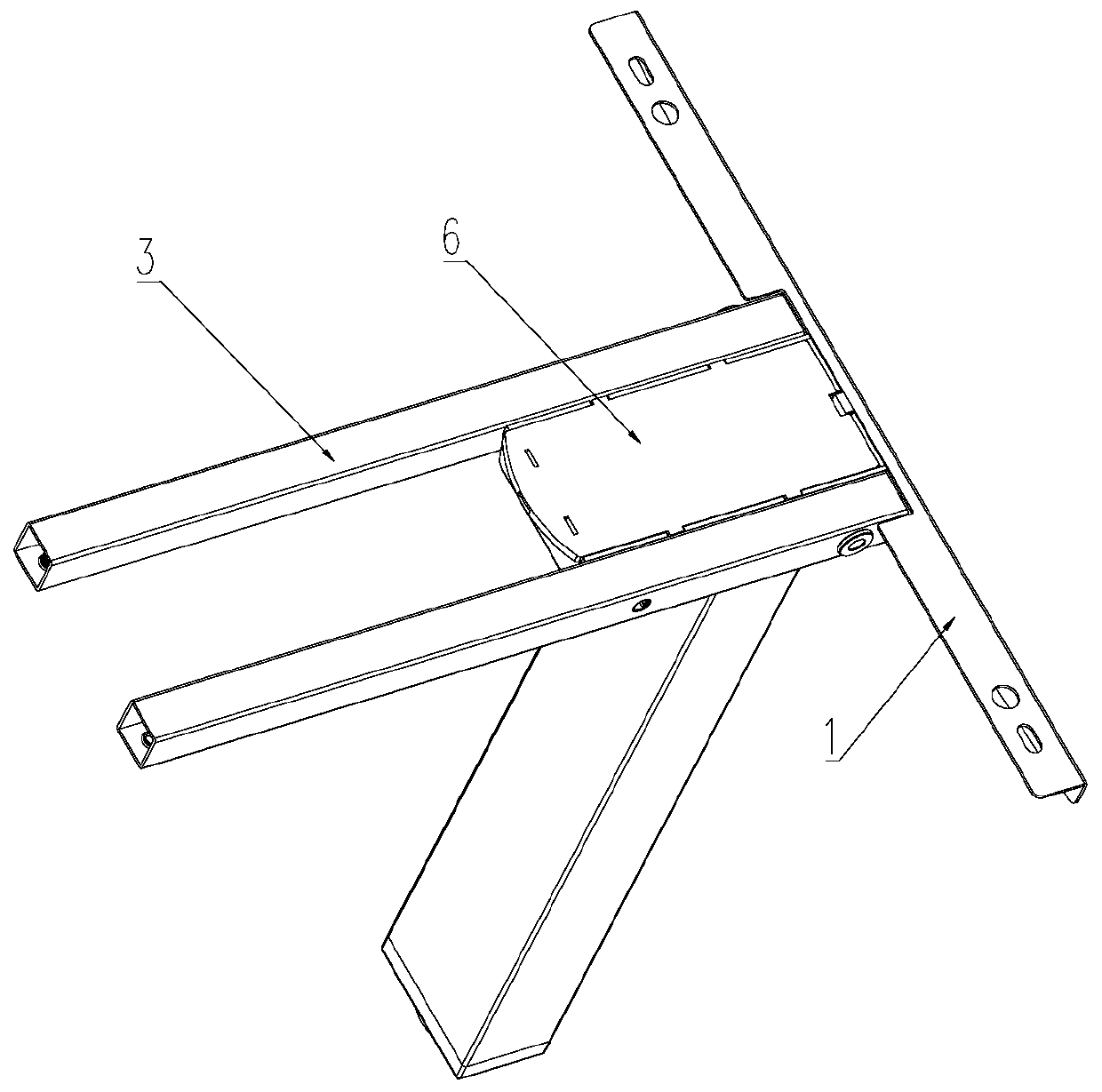

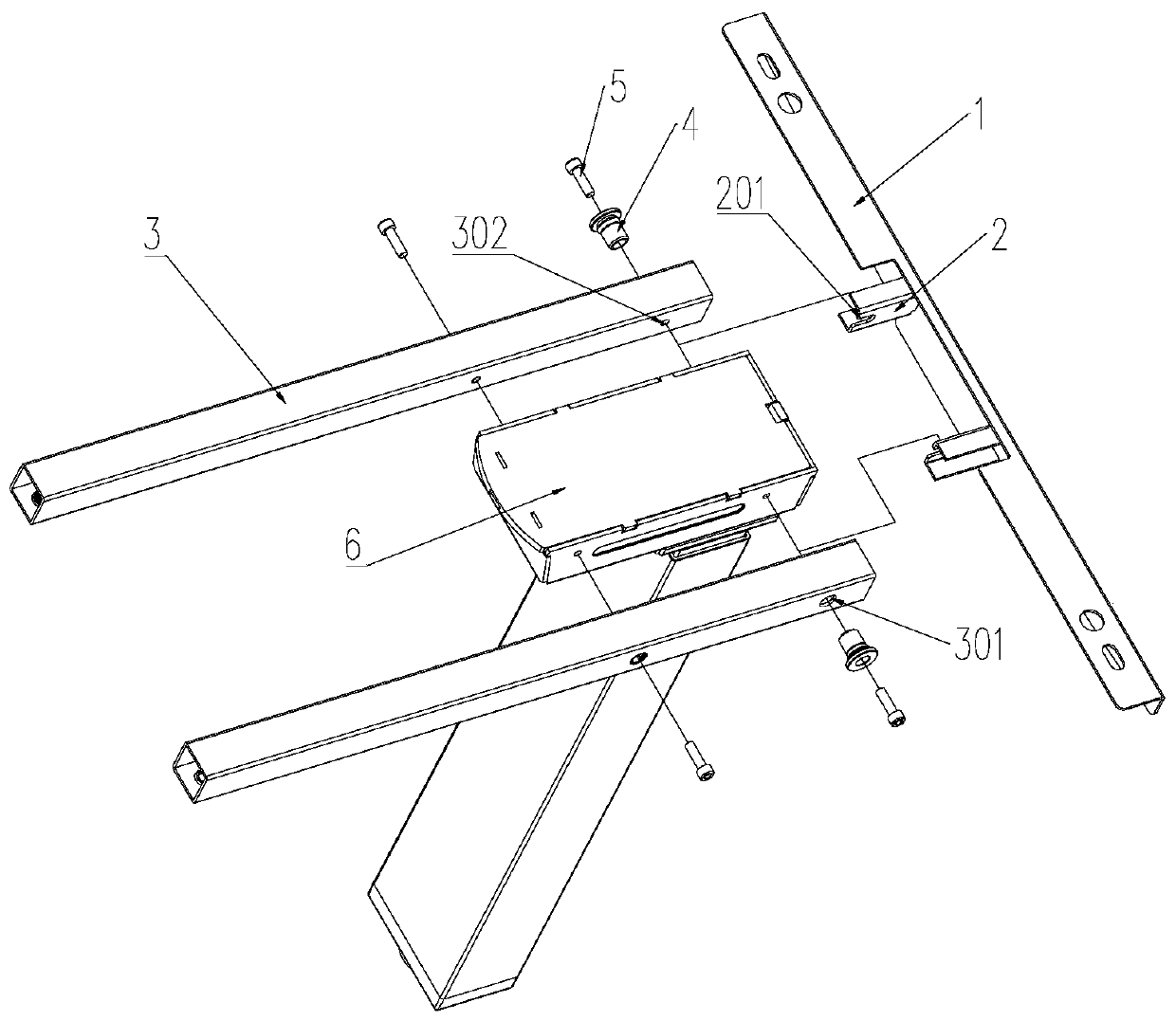

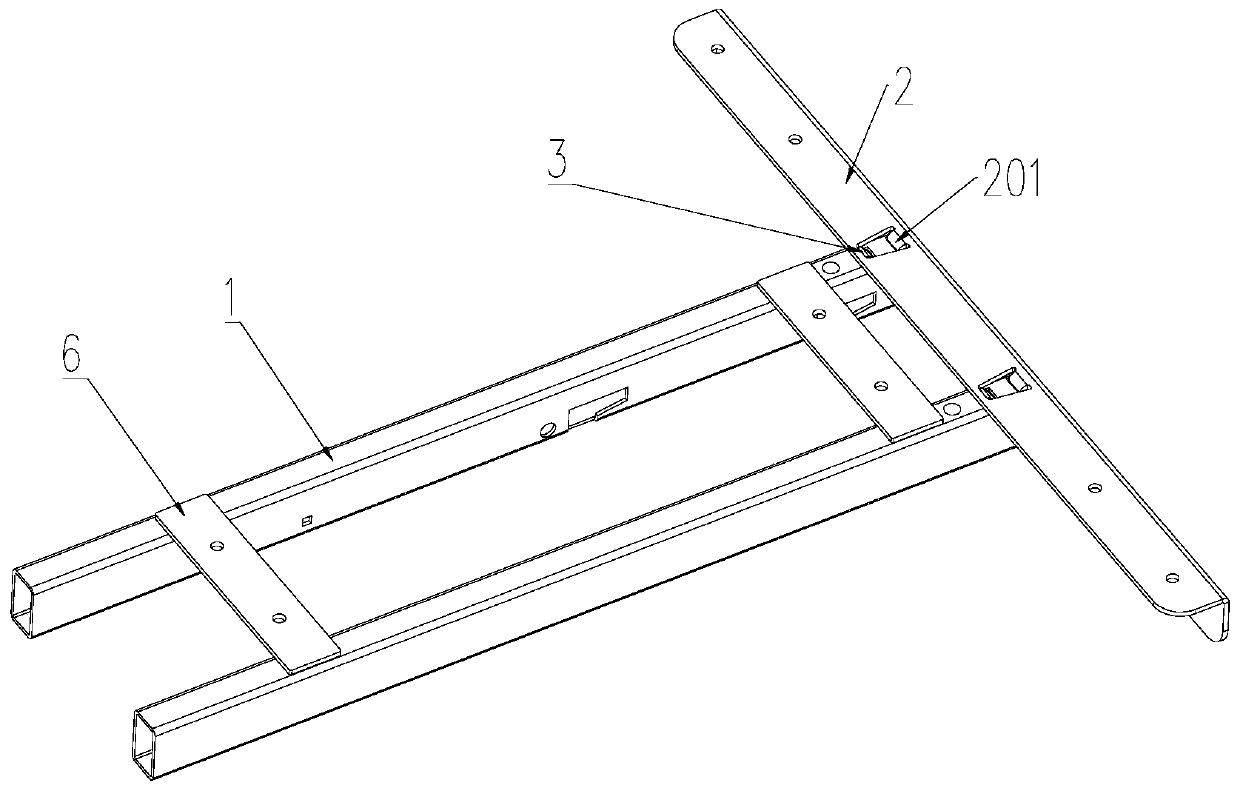

[0036] See Figure 3-7 , a rapidly assembled desktop support of the present invention can be matched with corresponding desktop boards to form a dining table, desk, office desk, conference table, student desk or coffee table, etc., with a beam 1 and a longitudinal beam 2 perpendicular to the beam 1.

[0037] A locking mechanism 3 is fixed on the crossbeam 1 , and the locking mechanism 3 is a leaf spring. The crossbeam 1 is provided with a first through hole 101 for the locking mechanism 3 to pop out. The locking mechanism 3 is made of spring steel. The locking mechanism 3 is composed of a connecting section 301 and a hemming section 302. The connecting section 301 and the hemming section 302 are integrally structured. The locking mechanism 3 is connected to the beam 1 through its connecting section 301 , the hemming section 302 has a pop-up part, the pop-up part includes a peak part 3022 and a guide part 3021 connected end to end, and the pop-up part pops out from the first th...

Embodiment 2

[0049] See Figure 8 , compared with Embodiment 1, the difference of Embodiment 2 is that the locking mechanism 3 and the crossbeam 1 are integrally structured, and the locking mechanism 3 is a part processed by the crossbeam 1. Specifically, the locking mechanism 3 utilizes the crossbeam 1 Stamping itself.

Embodiment 3

[0051] See Figure 9-10 , compared with embodiment 1, the difference of embodiment 3 is: the number of cross beams 1 is two groups, two groups of cross beams 1 are arranged along the length direction of the desktop bracket and distributed symmetrically left and right, and the inner cavities of two groups of cross beams 1 are interspersed There are connecting rods 4, and the number of connecting rods 4 is two. After the distance between the two groups of beams 1 is adjusted, they are respectively fixed with the corresponding ends of the connecting rods 4, so as to realize the adjustable length of the desktop support.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com