Feed processing and forming device for animal husbandry

A molding device and feed processing technology, applied in feed, mixer with rotary stirring device, application and other directions, can solve the problems of inability to guarantee the nutritional value of feed, low utilization rate of straw, quality of life of filmmakers, etc., and achieve the degree of production automation High, good crushing effect, environmental protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

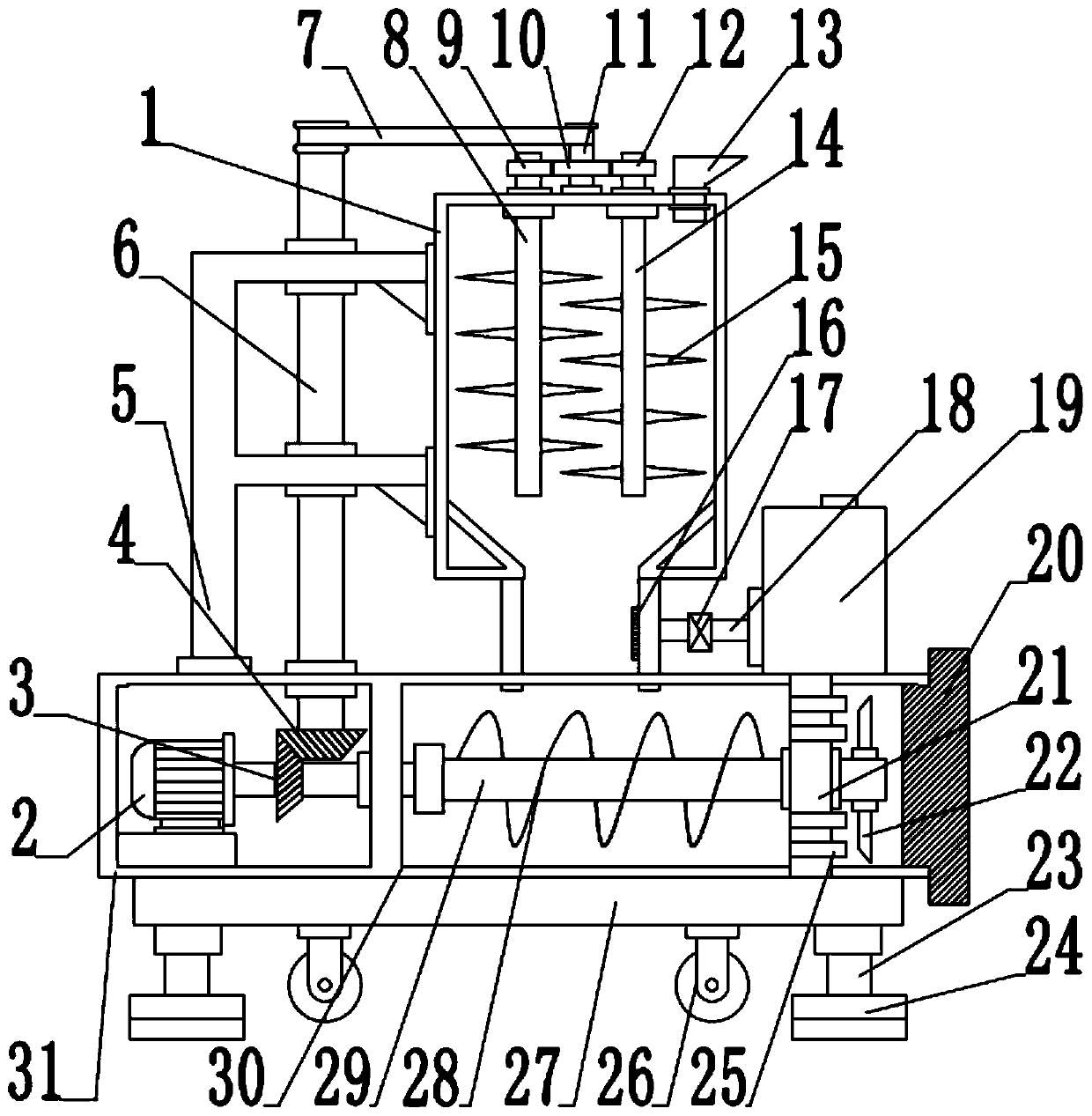

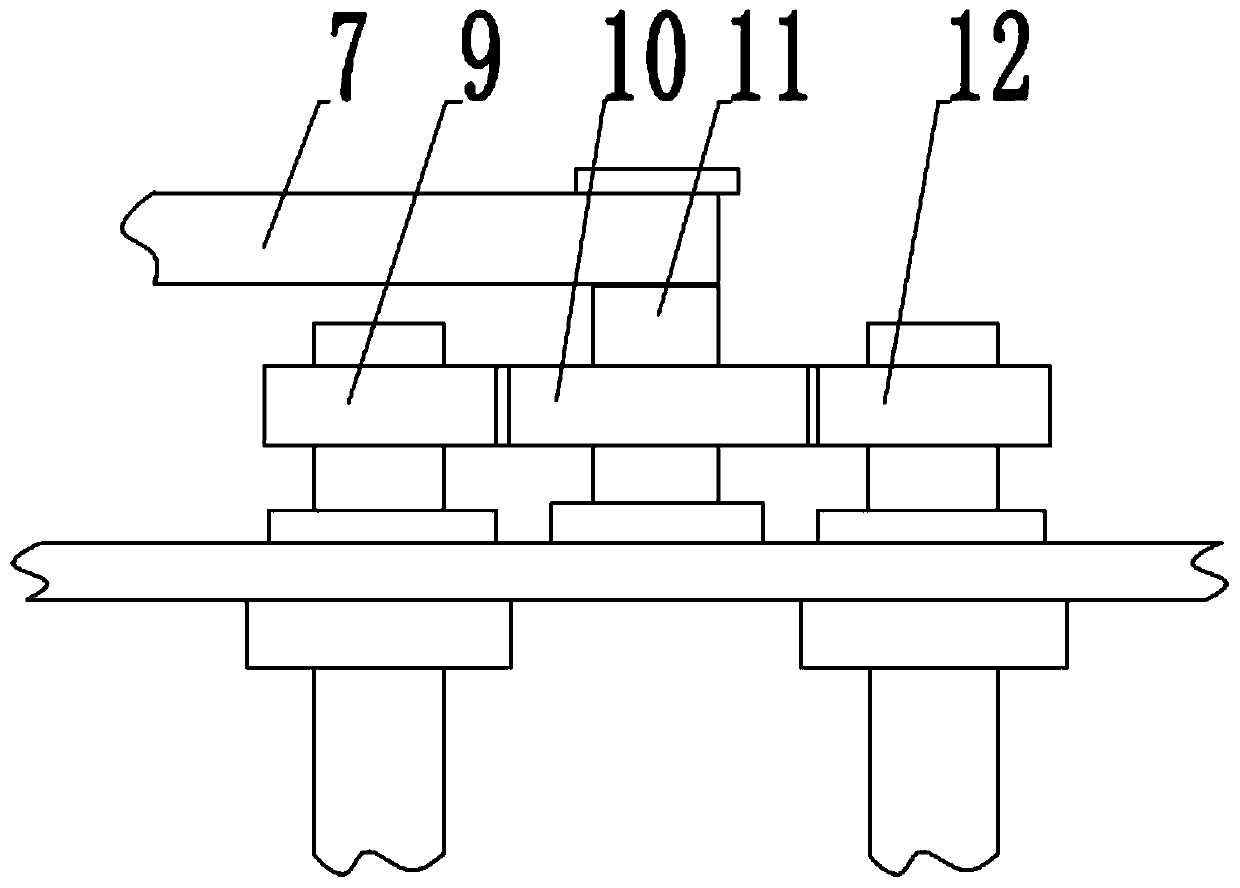

[0021] see Figure 1-3 , a feed processing molding device for animal husbandry, comprising a stirring box 1, a No. 1 stirring shaft 8 and a No. 2 stirring shaft 14 are arranged in the stirring box 1, and the No. 1 stirring shaft 8 and the No. 2 stirring shaft 14 are all fixed Connect the crushing knife 15, the top of the mixing box 1 is provided with a transmission assembly, the bottom of the mixing box 1 is provided with a molding barrel 30, and a rotating shaft 29 is arranged horizontally in the molding barrel 30, and a spiral blade 28 is arranged on the rotating shaft 29. One side of the barrel 30 is fixedly connected to the mold plate 21, and a plurality of discharge holes 25 are arranged through the mold plate 21. The side of the forming barrel 30 away from the mold plate 21 is fixedly connected to the drive box 31, and the drive box 31 is fixedly connected to the drive motor. 2. The top of the drive box 31 is fixedly connected to the F-shaped bracket 5, the transverse st...

Embodiment 2

[0026] see Figure 1-3 , the other content of this embodiment is the same as that of Embodiment 1, the difference is that: the top side of the stirring box 1 is provided with a feed inlet 13, the bottom end of the stirring box 1 is fixedly connected with the molding barrel 30, and the The pulverizing knives 15 on the No. 1 stirring shaft 8 and the No. 2 stirring shaft 14 are arranged at intervals of dislocation up and down.

[0027] In the implementation process of the present invention, when in use, the device is moved to a suitable position, supported and stabilized by the hydraulic cylinder 23, put straw, etc. The No. 1 bevel gear 3 on the drive shaft drives the No. 2 bevel gear 4 so that the transmission rod 6 rotates, and the transmission rod 6 drives the transmission shaft 11 to rotate through the transmission belt 7, so that the No. 1 gear 10 rotates and drives the No. 2 gear 9 and the No. 3 gear. No. gear 12 rotates, and the No. 1 stirring shaft 8 and No. 2 stirring s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com