Electric automatic feed mixing device

A technology of electrical automation and mixing device, which is applied in the direction of feed, mixer, mixer with rotary mixing device, etc. Mixing and other problems, to achieve the effect of good mixing and crushing, reducing labor and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

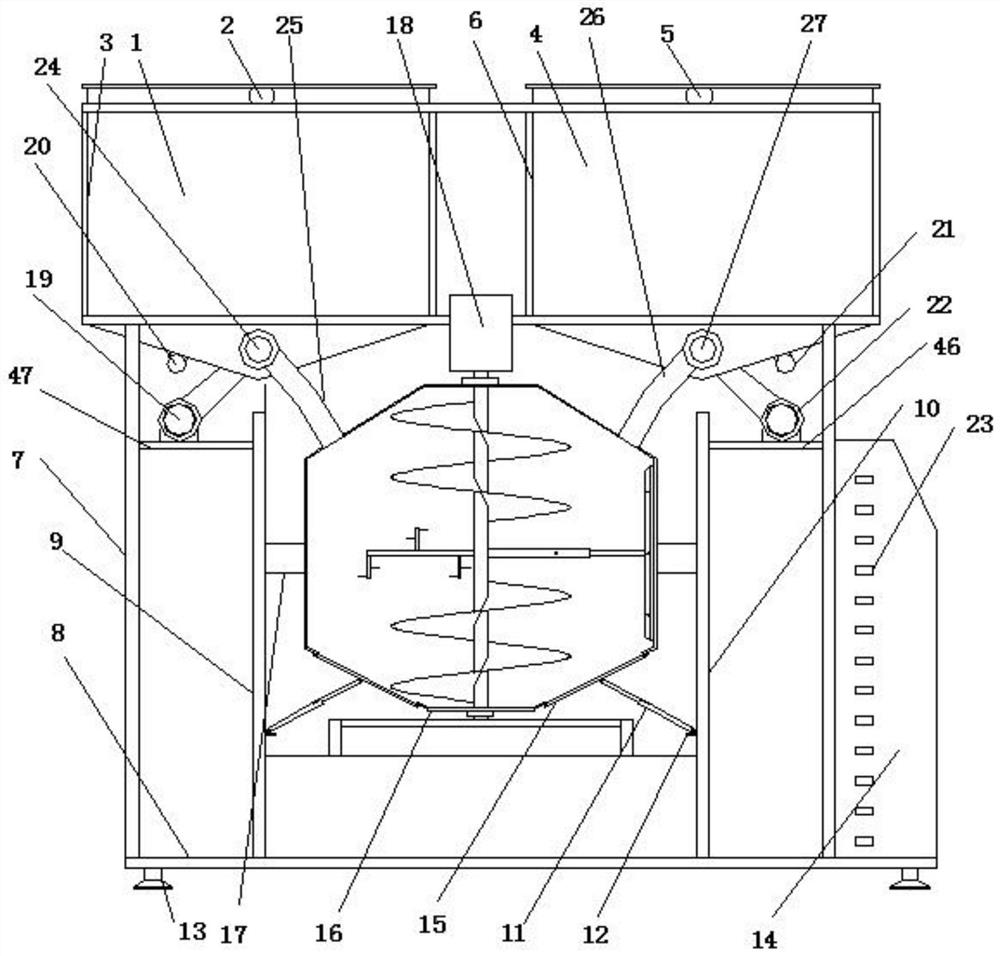

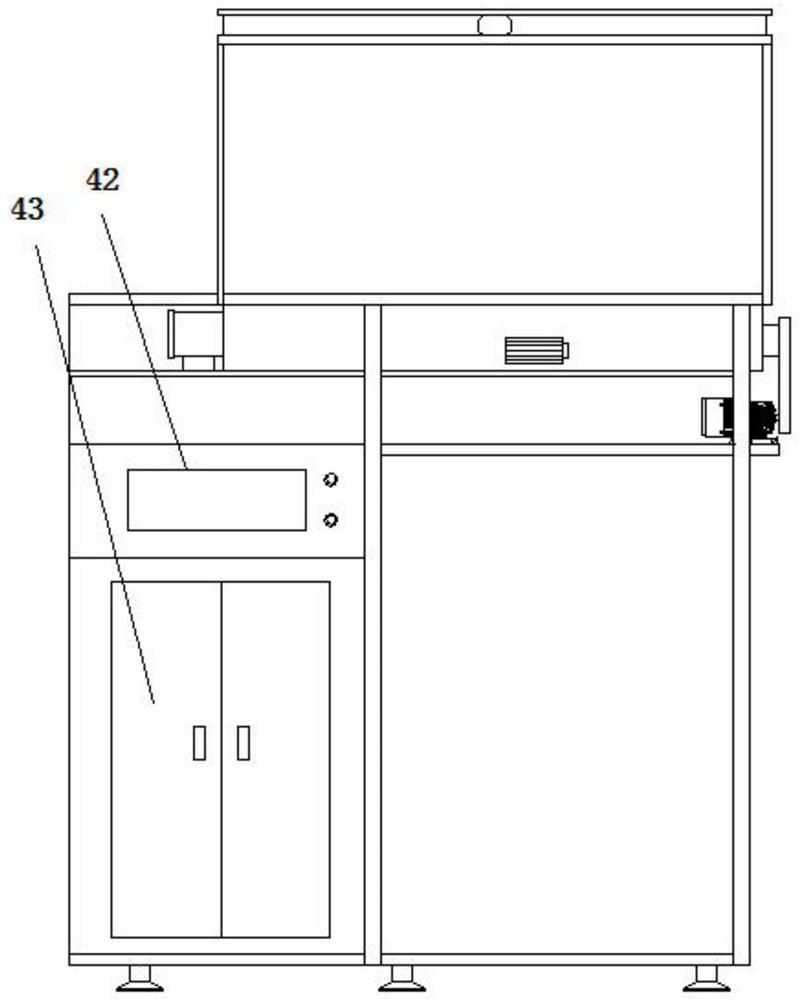

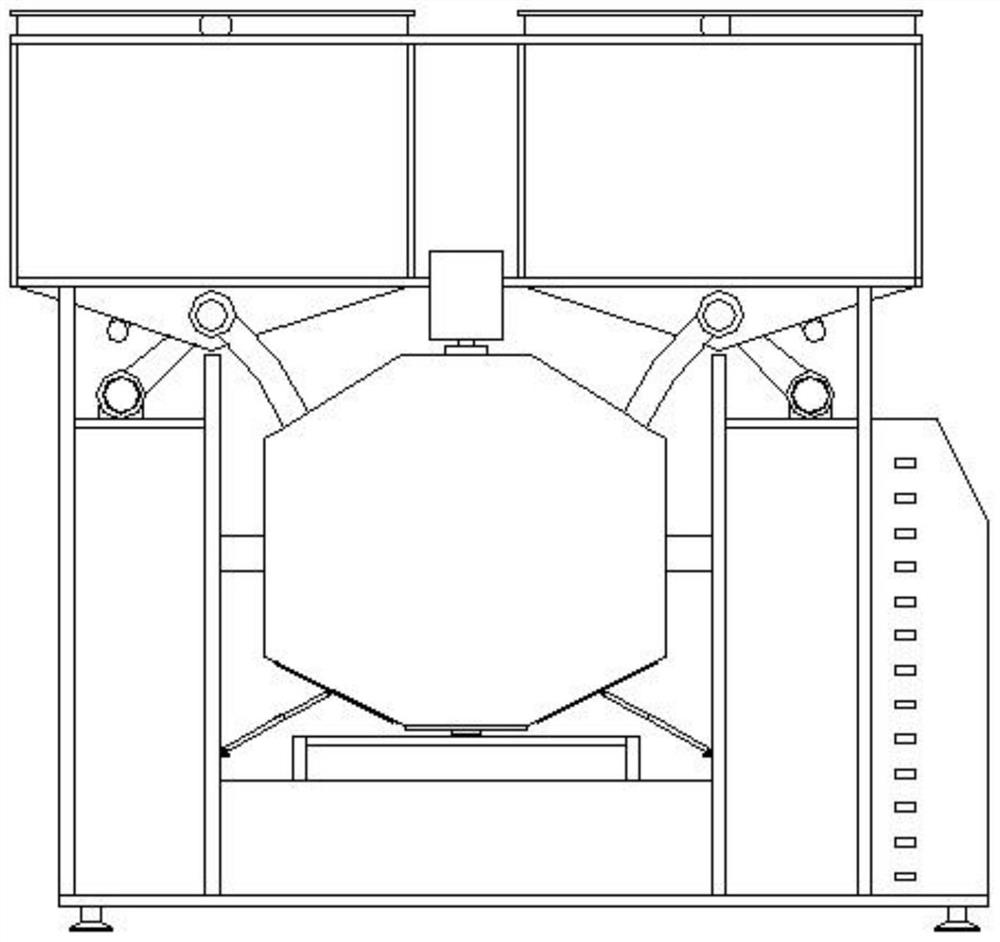

[0017] Such as Figure 1-Figure 7 Shown:

[0018]The electric automation feed mixing device is characterized in that the bottom bracket 8 is provided with symmetrical vertical plates I9 and vertical plates II10, and the vertical plates I9 and vertical plates II10 are connected to the stirring device through the connecting rod 17, and the stirring device includes a motor I18 And the stirring box 16, the motor I18 is located in the middle position directly above the stirring box 16, the motor I18 is connected to the top of the rotating shaft 29, and the bottom of the rotating shaft 29 is connected to the bearing seat 31, and the motor I18 drives the rotating shaft 29 to rotate, and the rotation The upper and lower parts of the shaft 29 are respectively provided with mutually symmetrical helical pieces I28 and helical piece II30. The helical piece I28 and the helical piece II30 transport the material 45 to the middle position of the mixing box 16 respectively, and stir while conv...

Embodiment 2

[0020] Such as Figure 1-Figure 7 Shown:

[0021] The electric automation feed mixing device is characterized in that the bottom bracket 8 is provided with symmetrical vertical plates I9 and vertical plates II10, and the vertical plates I9 and vertical plates II10 are connected to the stirring device through the connecting rod 17, and the stirring device includes a motor I18 And the stirring box 16, the motor I18 is located in the middle position directly above the stirring box 16, the motor I18 is connected to the top of the rotating shaft 29, and the bottom of the rotating shaft 29 is connected to the bearing seat 31, and the motor I18 drives the rotating shaft 29 to rotate, and the rotation The upper and lower parts of the shaft 29 are respectively provided with mutually symmetrical helical pieces I28 and helical piece II30. The helical piece I28 and the helical piece II30 transport the material 45 to the middle position of the mixing box 16 respectively, and stir while con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com